Gypsum joint compound typically requires mixing with water before application, offering customization in consistency and setting time for drywall finishing projects. Ready-mix joint compound is pre-mixed and convenient for quick repairs or small patch jobs, providing ease of use without preparation. Both compounds effectively fill gaps, but gypsum joint compound is preferred for professional-grade drywall taping due to its stronger adhesion and faster drying properties.

Table of Comparison

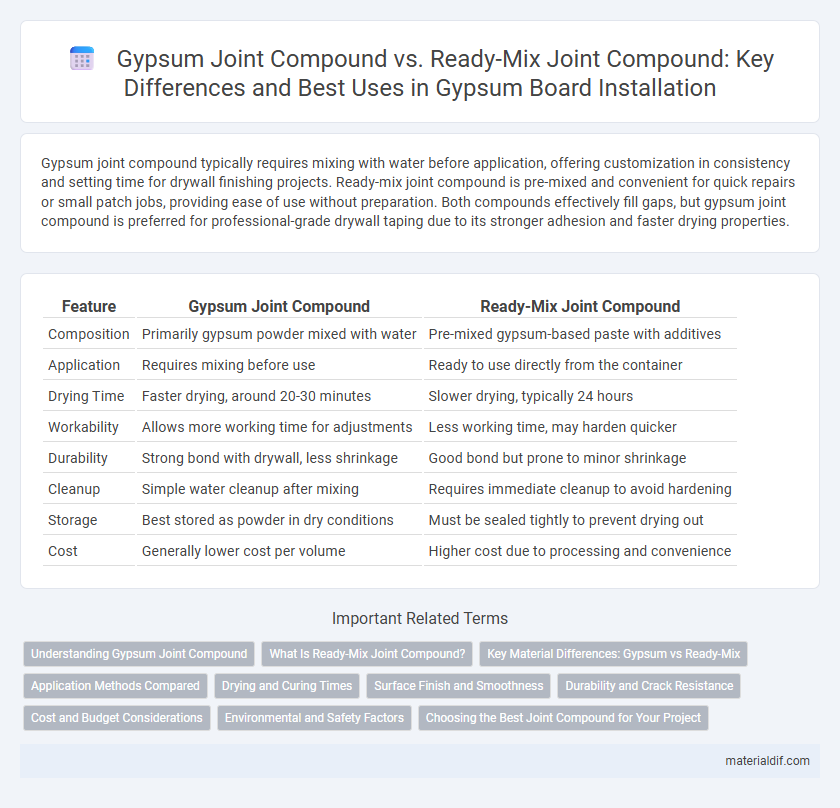

| Feature | Gypsum Joint Compound | Ready-Mix Joint Compound |

|---|---|---|

| Composition | Primarily gypsum powder mixed with water | Pre-mixed gypsum-based paste with additives |

| Application | Requires mixing before use | Ready to use directly from the container |

| Drying Time | Faster drying, around 20-30 minutes | Slower drying, typically 24 hours |

| Workability | Allows more working time for adjustments | Less working time, may harden quicker |

| Durability | Strong bond with drywall, less shrinkage | Good bond but prone to minor shrinkage |

| Cleanup | Simple water cleanup after mixing | Requires immediate cleanup to avoid hardening |

| Storage | Best stored as powder in dry conditions | Must be sealed tightly to prevent drying out |

| Cost | Generally lower cost per volume | Higher cost due to processing and convenience |

Understanding Gypsum Joint Compound

Gypsum joint compound, also known as drywall mud, is a powder that requires mixing with water before application, providing superior adhesion and faster drying times compared to ready-mix joint compound. Ready-mix joint compound is pre-mixed and convenient for small repairs or finishing touches but may contain fillers that reduce bonding strength and durability. Understanding the composition and performance differences between gypsum joint compound and ready-mix options ensures optimal results for drywall finishing projects.

What Is Ready-Mix Joint Compound?

Ready-mix joint compound is a pre-mixed gypsum-based product formulated for drywall installation and repair, designed for immediate use without the need for mixing powder and water. This compound typically contains gypsum, limestone, and binders, ensuring a smooth consistency that simplifies application and reduces preparation time compared to traditional dry powders. Ready-mix joint compound offers consistent quality, minimizes mess, and maintains excellent adhesion and sanding properties essential for seamless drywall finishing.

Key Material Differences: Gypsum vs Ready-Mix

Gypsum joint compound mainly consists of powdered gypsum that requires mixing with water before application, providing superior hardness and shrinkage control. Ready-mix joint compound is a pre-mixed blend containing gypsum and additional additives like binders and preservatives, offering convenience but potentially softer drying properties. The primary material difference lies in gypsum's purity and customization potential versus ready-mix formulations designed for ease of use and extended shelf life.

Application Methods Compared

Gypsum joint compound typically requires mixing with water to achieve the desired consistency, allowing for customization depending on the project's needs, while ready-mix joint compound comes pre-mixed and is immediately applicable, saving preparation time. Application methods for gypsum joint compound involve using taping knives or hawks and trowels, often needing more skill to manage drying times and mixing ratios. Ready-mix joint compound provides ease of use for quick repairs and finishing touches, with smoother consistency and less cracking during application compared to gypsum-based compounds.

Drying and Curing Times

Gypsum joint compound typically requires longer drying and curing times due to its powder form needing water mixing, which allows for greater control over consistency but extends the overall set time. Ready-mix joint compound offers faster drying and curing times as it comes pre-mixed with optimized moisture levels, enabling quicker application and sanding processes. The choice between the two depends on project timelines, with gypsum joint compound favored for large-scale taping jobs and ready-mix preferred for rapid repairs and finishing coats.

Surface Finish and Smoothness

Gypsum joint compound typically offers superior surface finish and smoothness due to its finer texture and better adherence properties, making it ideal for detailed drywall repairs and finishing. Ready-mix joint compound provides convenience with pre-mixed consistency but may require additional sanding to achieve the same level of smoothness as gypsum-based alternatives. The choice between the two affects the final appearance and ease of application in drywall finishing projects.

Durability and Crack Resistance

Gypsum joint compound offers superior durability due to its high calcium sulfate content, which enhances its structural integrity over time. Ready-mix joint compound contains acrylic binders that provide excellent crack resistance and flexibility, making it ideal for environments prone to slight movements. Selecting the appropriate compound depends on balancing the need for long-lasting strength with the ability to withstand potential cracking from structural shifts.

Cost and Budget Considerations

Gypsum joint compound typically offers a lower initial cost per batch compared to ready-mix joint compound, making it a budget-friendly option for large-scale projects requiring extensive taping and finishing. Ready-mix joint compound, while generally more expensive upfront due to processing and packaging, reduces labor costs and material waste by eliminating mixing time and ensuring consistent quality. Choosing between the two depends on project size and labor availability, with gypsum joint compound favoring cost efficiency for larger crews and ready-mix providing convenience and time savings for smaller teams or tight deadlines.

Environmental and Safety Factors

Gypsum joint compound typically contains fewer volatile organic compounds (VOCs) compared to many ready-mix joint compounds, resulting in improved indoor air quality and reduced environmental impact. Ready-mix joint compounds often include additives and preservatives that can release harmful emissions during application and drying, posing greater health risks to workers without proper ventilation. Choosing gypsum-based compounds with low VOC content supports safer handling practices and aligns with eco-friendly building standards such as LEED certification.

Choosing the Best Joint Compound for Your Project

Gypsum joint compound offers a superior finish with excellent adhesion, making it ideal for detailed drywall work and repairs requiring multiple coats. Ready-mix joint compound provides convenience with its pre-mixed consistency, saving time for projects that demand quick application and minimal preparation. Selecting the best joint compound depends on project size, drying time preference, and the complexity of surface repairs.

Gypsum joint compound vs Ready-mix joint compound Infographic

materialdif.com

materialdif.com