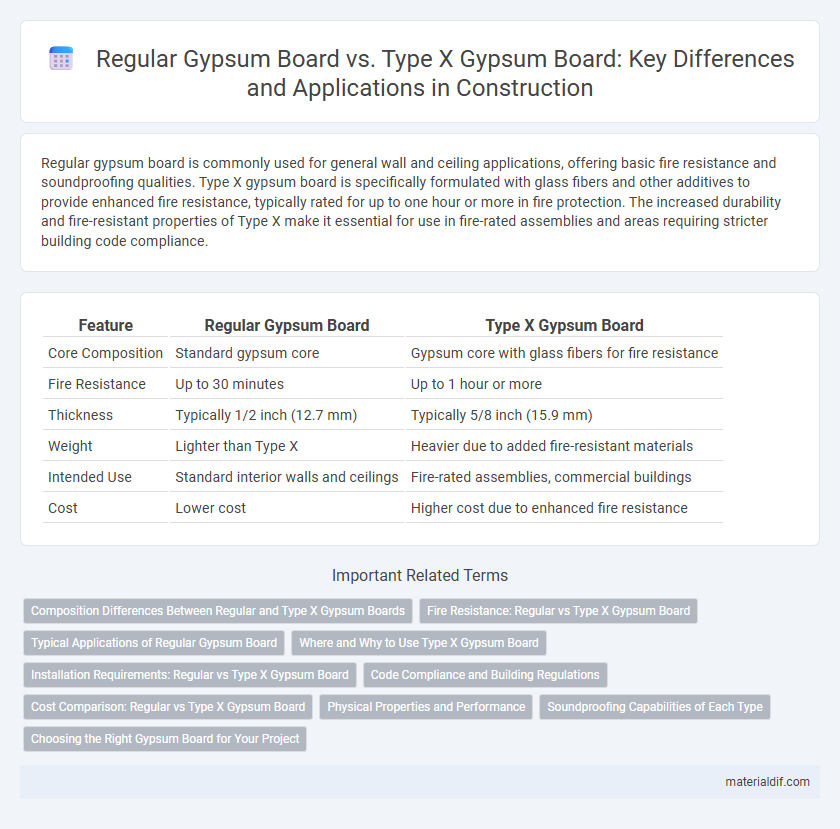

Regular gypsum board is commonly used for general wall and ceiling applications, offering basic fire resistance and soundproofing qualities. Type X gypsum board is specifically formulated with glass fibers and other additives to provide enhanced fire resistance, typically rated for up to one hour or more in fire protection. The increased durability and fire-resistant properties of Type X make it essential for use in fire-rated assemblies and areas requiring stricter building code compliance.

Table of Comparison

| Feature | Regular Gypsum Board | Type X Gypsum Board |

|---|---|---|

| Core Composition | Standard gypsum core | Gypsum core with glass fibers for fire resistance |

| Fire Resistance | Up to 30 minutes | Up to 1 hour or more |

| Thickness | Typically 1/2 inch (12.7 mm) | Typically 5/8 inch (15.9 mm) |

| Weight | Lighter than Type X | Heavier due to added fire-resistant materials |

| Intended Use | Standard interior walls and ceilings | Fire-rated assemblies, commercial buildings |

| Cost | Lower cost | Higher cost due to enhanced fire resistance |

Composition Differences Between Regular and Type X Gypsum Boards

Regular gypsum board consists primarily of a gypsum core sandwiched between paper facings, offering standard fire resistance and utility for most wall applications. Type X gypsum board incorporates glass fibers or other reinforcing materials within the core, enhancing its fire resistance by increasing structural integrity under high temperatures. This compositional difference enables Type X boards to meet stricter fire-rating standards, making them suitable for fire-rated assembly designs.

Fire Resistance: Regular vs Type X Gypsum Board

Regular gypsum board provides basic fire resistance suitable for everyday wall applications, while Type X gypsum board is engineered with non-combustible fibers and a denser core to enhance fire resistance significantly. Type X gypsum board typically achieves a fire resistance rating of up to 1 hour or more, making it ideal for fire-rated walls and ceilings in commercial and residential buildings. The improved fire performance of Type X gypsum board helps to delay fire spread, protect structural elements, and improve occupant safety.

Typical Applications of Regular Gypsum Board

Regular gypsum board is commonly used in standard interior walls and ceilings for residential and commercial buildings due to its cost-effectiveness and ease of installation. It serves well in areas with low moisture and minimal fire resistance requirements, such as bedrooms, living rooms, and offices. This type of gypsum board provides a smooth surface ideal for painting or wallpapering, making it a versatile option for everyday construction projects.

Where and Why to Use Type X Gypsum Board

Type X gypsum board is specifically designed for fire resistance, making it essential for walls and ceilings in commercial buildings, multi-family residences, and areas with strict fire codes. It contains glass fibers that increase its ability to withstand fire longer than regular gypsum board, providing critical time for evacuation and fire suppression. Use Type X gypsum board in fire-rated assemblies where enhanced protection is required to meet building safety standards and ensure occupant safety.

Installation Requirements: Regular vs Type X Gypsum Board

Regular gypsum board requires standard installation techniques using nails or screws spaced 12 inches apart on ceilings and 16 inches on walls, while Type X gypsum board mandates closer fastener spacing, typically 8 inches on ceilings and 12 inches on walls, to meet fire resistance standards. Type X boards must be installed with compatible joint compounds and tapes designed for fire-rated assemblies to maintain their integrity under high temperatures. Proper sealing of joints and penetrations is critical for Type X gypsum board to achieve the UL fire ratings specified in building codes.

Code Compliance and Building Regulations

Regular gypsum board meets basic fire resistance requirements but often falls short of stringent building codes demanding enhanced safety measures. Type X gypsum board is engineered with glass fibers and special additives, providing up to one-hour fire resistance, making it compliant with International Building Code (IBC) fire separation standards. Building regulations frequently mandate Type X boards in walls and ceilings around high-risk areas such as garages, corridors, and stairwells to ensure occupant safety and structural integrity.

Cost Comparison: Regular vs Type X Gypsum Board

Regular gypsum board typically costs less per square foot compared to Type X gypsum board, making it a budget-friendly option for standard interior walls. Type X gypsum board, designed with fire-resistant additives and multiple glass fibers, demands a higher price due to enhanced safety features required in fire-rated assemblies. The cost differential can range from 20% to 50%, reflecting the specialized manufacturing process and compliance with fire safety codes.

Physical Properties and Performance

Regular gypsum board features a standard paper facing with a gypsum core, providing basic fire resistance and moderate durability, ideal for typical interior walls and ceilings. Type X gypsum board incorporates glass fibers within the core, enhancing its fire resistance to withstand fire for up to one hour or more, making it suitable for fire-rated assemblies and commercial construction. Physically, Type X is denser and thicker than regular gypsum board, contributing to improved impact resistance and structural integrity under fire exposure.

Soundproofing Capabilities of Each Type

Regular gypsum board offers basic soundproofing properties suitable for standard residential walls, attenuating typical noise levels. Type X gypsum board enhances soundproofing with a denser core and additional layers of fiberglass, providing superior noise reduction and improved fire resistance. These sound dampening features make Type X ideal for multi-family housing, commercial buildings, and environments requiring stringent sound control.

Choosing the Right Gypsum Board for Your Project

Regular gypsum board offers cost-effective, lightweight wall solutions ideal for non-fire-rated interior applications, while Type X gypsum board incorporates glass fibers for enhanced fire resistance, making it essential for code-compliant fire-rated assemblies. Selecting the right gypsum board depends on building code requirements, fire safety needs, and project specifications, with Type X typically specified where fire-rated walls or ceilings are mandated. Ensuring compliance with local fire regulations and project demands optimizes safety and performance in construction.

Regular gypsum board vs Type X gypsum board Infographic

materialdif.com

materialdif.com