Gypsum powder and limestone powder differ primarily in composition and applications; gypsum is calcium sulfate dihydrate, making it ideal for wallboards and cement setting, while limestone powder is mainly calcium carbonate, used in construction aggregates and soil conditioning. Gypsum powder improves workability and controls setting times in cement, whereas limestone powder primarily acts as a filler to enhance strength and reduce costs. Both powders contribute to environmental sustainability by enabling recycling and reducing raw material consumption in construction materials.

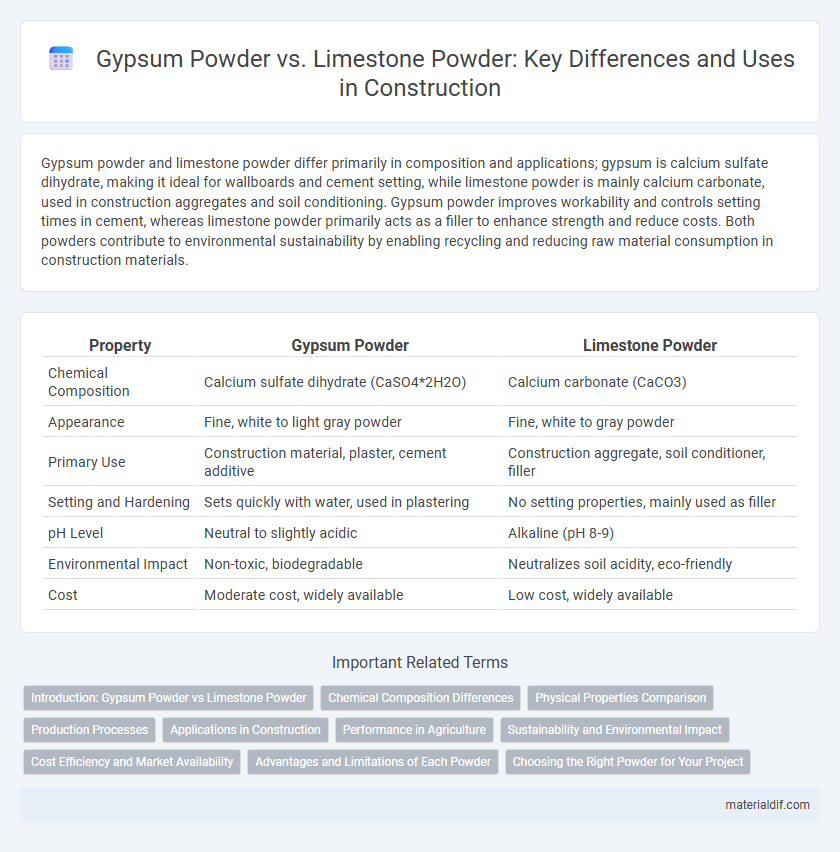

Table of Comparison

| Property | Gypsum Powder | Limestone Powder |

|---|---|---|

| Chemical Composition | Calcium sulfate dihydrate (CaSO4*2H2O) | Calcium carbonate (CaCO3) |

| Appearance | Fine, white to light gray powder | Fine, white to gray powder |

| Primary Use | Construction material, plaster, cement additive | Construction aggregate, soil conditioner, filler |

| Setting and Hardening | Sets quickly with water, used in plastering | No setting properties, mainly used as filler |

| pH Level | Neutral to slightly acidic | Alkaline (pH 8-9) |

| Environmental Impact | Non-toxic, biodegradable | Neutralizes soil acidity, eco-friendly |

| Cost | Moderate cost, widely available | Low cost, widely available |

Introduction: Gypsum Powder vs Limestone Powder

Gypsum powder, primarily composed of calcium sulfate dihydrate, is widely used in construction for its superior setting and fire-resistant properties, whereas limestone powder mainly consists of calcium carbonate and serves as an economical filler in cement and concrete. Gypsum powder controls the setting time of cement effectively, improving durability and reducing cracking, while limestone powder enhances workability and reduces CO2 emissions by partially replacing cement. The distinct chemical compositions and functional roles of gypsum and limestone powders determine their specific applications in the building industry.

Chemical Composition Differences

Gypsum powder primarily consists of calcium sulfate dihydrate (CaSO4*2H2O), providing sulfur and calcium essential for soil and construction applications. Limestone powder is mainly calcium carbonate (CaCO3), which serves as a neutralizing agent for acidic soils and a filler in industrial processes. The presence of sulfur in gypsum distinguishes its chemical composition from the carbonate-based limestone, influencing their respective uses and benefits.

Physical Properties Comparison

Gypsum powder exhibits a finer particle size and higher moisture content compared to limestone powder, influencing its superior workability in construction applications. The soft, crystalline structure of gypsum powder results in lower density and greater solubility than the denser, more granular limestone powder. Gypsum's unique setting and binding properties make it essential for plaster and drywall, whereas limestone powder primarily serves as a filler and pH adjuster in various industries.

Production Processes

Gypsum powder is produced through the calcination of natural gypsum, where controlled heating removes water molecules to create a fine, consistent powder primarily used in construction and agriculture. Limestone powder is made by crushing and grinding limestone rock, followed by optional heating to produce quicklime or hydrated lime, widely applied in cement manufacturing and soil conditioning. The calcination temperatures and raw material compositions significantly differentiate gypsum powder production from the more mechanically focused processes used for limestone powder.

Applications in Construction

Gypsum powder is widely used in construction for producing drywall, plaster, and cement due to its excellent setting and fire-resistant properties. Limestone powder serves primarily as a filler material in cement and concrete mixtures, enhancing strength and workability while reducing cost. Both materials contribute to durability and sustainability, but gypsum's role in improving fire resistance and surface finish distinguishes it from limestone in construction applications.

Performance in Agriculture

Gypsum powder enhances soil structure by improving water infiltration and providing essential calcium and sulfur nutrients, which promote healthier root development and higher crop yields. Limestone powder primarily adjusts soil pH by neutralizing acidity, but it lacks the sulfur content necessary for optimal plant growth. Gypsum's ability to improve soil physical properties and supply vital nutrients makes it more effective than limestone powder for agricultural performance.

Sustainability and Environmental Impact

Gypsum powder offers enhanced sustainability compared to limestone powder due to its role in reducing carbon emissions during cement production by controlling the setting time and improving durability. Unlike limestone powder, which requires extensive quarrying and energy-intensive calcination that releases significant CO2, gypsum is often sourced as an industrial byproduct, lowering environmental impact. Utilizing gypsum powder in construction materials supports waste valorization and decreases reliance on virgin mineral extraction, aligning with sustainable building practices.

Cost Efficiency and Market Availability

Gypsum powder offers cost efficiency due to its widespread availability and lower processing costs compared to limestone powder, which often requires extensive mining and refining. Market availability of gypsum powder is higher in construction and agricultural sectors, driven by steady demand in plaster, drywall, and soil amendment applications. Limestone powder, while versatile, tends to have fluctuating prices influenced by quarrying regulations and transportation expenses.

Advantages and Limitations of Each Powder

Gypsum powder offers superior fire resistance and enhances the setting time in cement mixtures, making it ideal for construction and plaster applications, but it can be more expensive and less abundant than limestone powder. Limestone powder provides excellent workability and is cost-effective for large-scale concrete production, yet it has lower sulfate resistance and less ability to control setting time compared to gypsum. Both powders serve distinct roles in construction, with gypsum preferred for durability and control, and limestone favored for economic and volumetric benefits.

Choosing the Right Powder for Your Project

Selecting gypsum powder over limestone powder enhances construction projects due to gypsum's superior setting time control and fire resistance properties. Limestone powder offers benefits in reducing shrinkage and improving workability but lacks the strength and durability provided by gypsum. Prioritizing gypsum powder is essential for applications requiring enhanced structural integrity and moisture regulation.

Gypsum powder vs Limestone powder Infographic

materialdif.com

materialdif.com