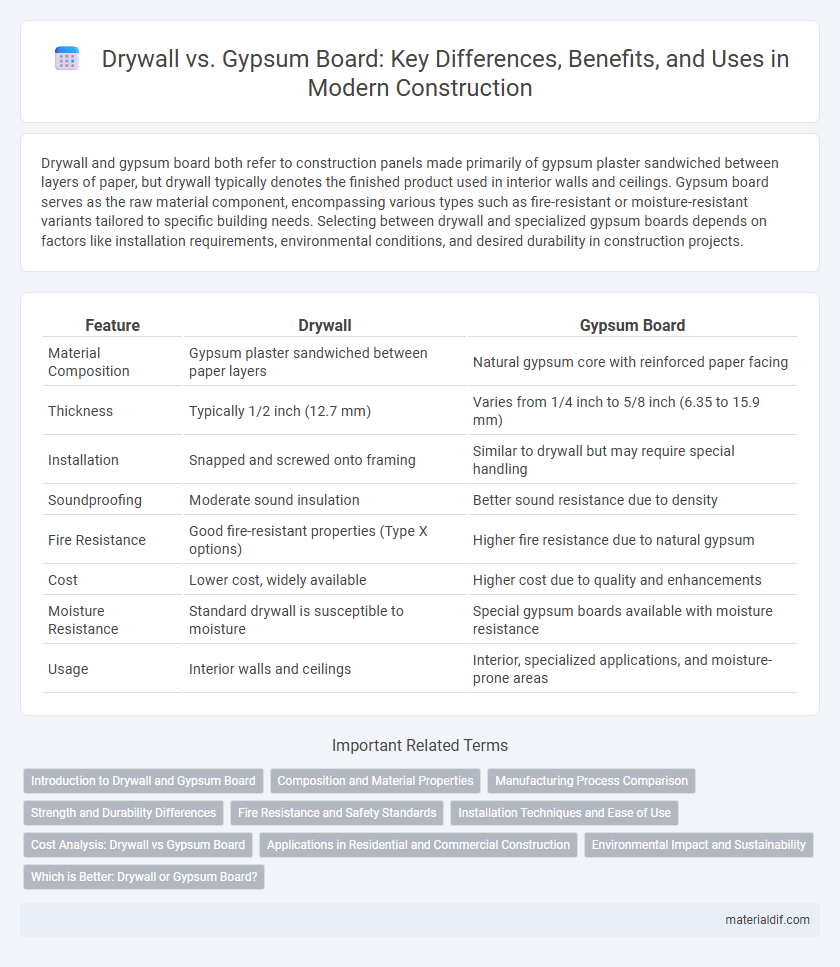

Drywall and gypsum board both refer to construction panels made primarily of gypsum plaster sandwiched between layers of paper, but drywall typically denotes the finished product used in interior walls and ceilings. Gypsum board serves as the raw material component, encompassing various types such as fire-resistant or moisture-resistant variants tailored to specific building needs. Selecting between drywall and specialized gypsum boards depends on factors like installation requirements, environmental conditions, and desired durability in construction projects.

Table of Comparison

| Feature | Drywall | Gypsum Board |

|---|---|---|

| Material Composition | Gypsum plaster sandwiched between paper layers | Natural gypsum core with reinforced paper facing |

| Thickness | Typically 1/2 inch (12.7 mm) | Varies from 1/4 inch to 5/8 inch (6.35 to 15.9 mm) |

| Installation | Snapped and screwed onto framing | Similar to drywall but may require special handling |

| Soundproofing | Moderate sound insulation | Better sound resistance due to density |

| Fire Resistance | Good fire-resistant properties (Type X options) | Higher fire resistance due to natural gypsum |

| Cost | Lower cost, widely available | Higher cost due to quality and enhancements |

| Moisture Resistance | Standard drywall is susceptible to moisture | Special gypsum boards available with moisture resistance |

| Usage | Interior walls and ceilings | Interior, specialized applications, and moisture-prone areas |

Introduction to Drywall and Gypsum Board

Drywall, also known as gypsum board, is a building material composed of a gypsum core sandwiched between two layers of paper. This versatile panel is widely used in interior wall and ceiling construction due to its ease of installation and fire-resistant properties. While both terms are often used interchangeably, drywall typically refers to the finished installation, whereas gypsum board emphasizes the raw material itself.

Composition and Material Properties

Drywall and gypsum board primarily consist of a core of gypsum plaster sandwiched between layers of paper, but drywall is a commercial term encompassing various gypsum board products designed for interior walls and ceilings. Gypsum board offers excellent fire resistance and soundproofing due to its calcined gypsum core, which contains chemically combined water that slows heat transfer. The paper facings of gypsum board add structural strength and finish quality, differentiating it from other drywall varieties that may include additives or alternative facings for moisture resistance or impact durability.

Manufacturing Process Comparison

Drywall and gypsum board share similar manufacturing processes involving the layering of a non-combustible core made primarily from calcium sulfate dihydrate, commonly known as gypsum, between sheets of heavy paper or fiberglass mats. Gypsum board manufacturing includes drying the gypsum slurry to form a solid core, trimming edges, and cutting panels to size, whereas drywall production often emphasizes enhanced formulations for improved moisture resistance and fire retardancy. Both processes require precision equipment for slurry mixing, continuous board forming, and controlled drying to ensure consistent thickness and durability.

Strength and Durability Differences

Drywall and gypsum board both consist primarily of gypsum plaster sandwiched between paper layers, but gypsum board typically features enhanced formulations that improve strength and impact resistance. Gypsum board often includes fiberglass or other reinforcing additives, making it more durable and less prone to cracking or sagging over time compared to standard drywall. These strength and durability differences make gypsum board a preferred choice in high-traffic or moisture-prone areas where long-lasting performance is critical.

Fire Resistance and Safety Standards

Drywall and gypsum board are often used interchangeably, but gypsum board specifically refers to panels made with a core of gypsum plaster pressed between two thick sheets of paper, offering superior fire resistance due to the non-combustible nature of gypsum. Fire-resistant gypsum boards, such as Type X, contain glass fibers that enhance fireproofing capabilities, meeting stringent safety standards like ASTM E119 and UL 263 for one-hour or two-hour fire ratings in residential and commercial buildings. These safety standards ensure gypsum boards not only slow fire spread but also maintain structural integrity during exposure, making them essential for compliance in building codes focused on occupant protection.

Installation Techniques and Ease of Use

Drywall and gypsum board share similar installation techniques involving measuring, cutting, securing panels to wall studs, and taping seams for a smooth finish. Gypsum board often offers enhanced fire resistance and moisture control properties, making it preferable for certain applications despite installation steps being largely identical. Ease of use depends on panel thickness and weight, with standard gypsum boards designed for straightforward handling by professionals and DIY enthusiasts alike.

Cost Analysis: Drywall vs Gypsum Board

Drywall and gypsum board are often used interchangeably, but their cost differences can impact project budgets significantly. Drywall typically costs between $0.30 to $0.50 per square foot, while gypsum board prices range from $0.25 to $0.75 depending on thickness and type, with specialty gypsum boards like moisture-resistant or fire-rated variants costing more. Labor expenses for installation of both materials are similar, but gypsum board may require additional finishing costs, influencing the overall cost analysis during material selection.

Applications in Residential and Commercial Construction

Drywall and gypsum board are essential materials in residential and commercial construction, offering fire resistance, sound insulation, and ease of installation. Gypsum board is commonly used for interior walls and ceilings in homes, offices, and retail spaces due to its moisture resistance and durability. In commercial construction, drywall systems often include specialized gypsum panels designed for enhanced performance in high-traffic or high-humidity environments such as hospitals and schools.

Environmental Impact and Sustainability

Gypsum board and drywall share similar environmental impacts due to their gypsum core, but drywall often incorporates recycled paper, enhancing sustainability by reducing waste. Manufacturing processes for both materials emit CO2, yet innovations in gypsum recycling and the use of synthetic gypsum from power plants decrease landfill accumulation. Sustainable practices prioritize gypsum board products with certifications like GREENGUARD or Cradle to Cradle, highlighting lower emissions and eco-friendly content.

Which is Better: Drywall or Gypsum Board?

Drywall and gypsum board are often used interchangeably, but gypsum board is a specific type of drywall made with a core of gypsum plaster. Gypsum board offers superior fire resistance and soundproofing compared to standard drywall, making it better suited for both residential and commercial construction. Choosing gypsum board enhances durability and structural integrity, especially in areas prone to moisture or impact.

Drywall vs Gypsum board Infographic

materialdif.com

materialdif.com