Type X gypsum is formulated with glass fibers to enhance fire resistance, making it ideal for applications requiring extended fire ratings. Type C gypsum typically contains more lime and offers greater hardness and durability but has lower fire-resistant properties compared to Type X. Choosing between Type X and Type C gypsum depends on the specific fire safety requirements and structural performance needed for a project.

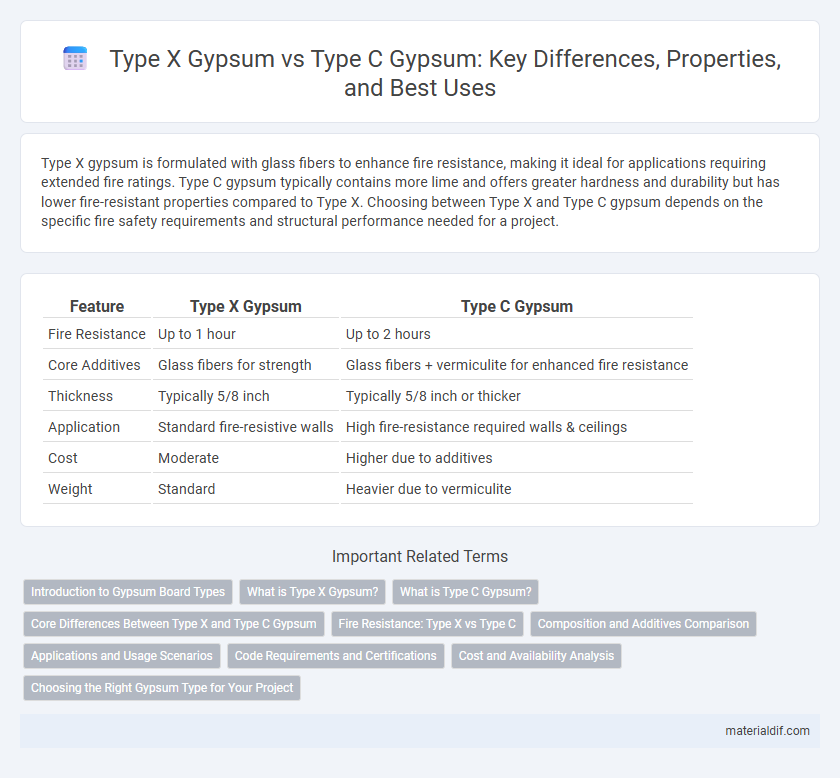

Table of Comparison

| Feature | Type X Gypsum | Type C Gypsum |

|---|---|---|

| Fire Resistance | Up to 1 hour | Up to 2 hours |

| Core Additives | Glass fibers for strength | Glass fibers + vermiculite for enhanced fire resistance |

| Thickness | Typically 5/8 inch | Typically 5/8 inch or thicker |

| Application | Standard fire-resistive walls | High fire-resistance required walls & ceilings |

| Cost | Moderate | Higher due to additives |

| Weight | Standard | Heavier due to vermiculite |

Introduction to Gypsum Board Types

Type X gypsum board features enhanced fire-resistant properties due to its dense core with non-combustible fibers, making it ideal for fire-rated wall and ceiling assemblies. Type C gypsum board offers superior fire protection with a thicker core and additional fire-retardant additives, providing longer burn resistance suitable for more demanding safety requirements. Both types serve specific roles in construction, balancing strength, fire resistance, and installation needs based on building codes and applications.

What is Type X Gypsum?

Type X gypsum is a fire-resistant drywall specifically designed to enhance fire protection in building construction. It contains non-combustible fibers and additives that increase its fire resistance compared to standard gypsum products like Type C gypsum. Commonly used in fire-rated wall assemblies, Type X gypsum helps meet building code requirements for fire safety.

What is Type C Gypsum?

Type C gypsum is a specialized fire-resistant drywall designed with enhanced additives to provide superior fire protection compared to standard gypsum boards. It typically contains fiberglass and other non-combustible materials, making it ideal for use in fire-rated wall assemblies and ceilings. Type C gypsum offers improved durability and thermal resistance, meeting stringent building codes for safety in residential and commercial construction.

Core Differences Between Type X and Type C Gypsum

Type X gypsum features enhanced fire-resistant core additives such as glass fibers, making it suitable for fire-rated wall assemblies, whereas Type C gypsum contains a special non-combustible core that provides improved sag resistance and better moisture tolerance. Type X drywall typically offers a fire-resistance rating of up to one hour, while Type C drywall is engineered to extend this rating beyond one hour in many applications due to its denser core composition. These core differences influence installation suitability, with Type X preferred for standard fire protection and Type C selected for environments requiring superior durability and extended fire resistance.

Fire Resistance: Type X vs Type C

Type X gypsum contains special glass fibers that enhance its fire resistance, providing up to one-hour protection in fire-rated wall assemblies. In contrast, Type C gypsum incorporates additional additives like vermiculite, which improves fire resistance beyond Type X, often achieving up to two-hour fire ratings. The higher density and specific additives in Type C gypsum make it the preferred choice for structures requiring superior fire protection.

Composition and Additives Comparison

Type X gypsum contains glass fibers and special additives such as vermiculite to enhance fire resistance, making it suitable for fire-rated walls and ceilings. Type C gypsum incorporates additional gypsum and other proprietary additives that improve its strength and moisture resistance, often used in applications requiring improved durability. The key compositional difference lies in Type X's fire-retardant additives versus Type C's emphasis on enhanced physical properties through increased gypsum content and moisture-resistant materials.

Applications and Usage Scenarios

Type X gypsum is primarily used in fire-resistant wall assemblies, such as fire-rated partitions in commercial buildings and multi-family residences, due to its enhanced fire-retardant additives. Type C gypsum offers even greater fire resistance and is ideal for high-risk areas like auditoriums, stairwells, and corridors requiring extended fire protection performance. Both types are essential in construction projects where fire safety codes mandate specific fire ratings, but Type C is preferred for more demanding fire-resistance requirements.

Code Requirements and Certifications

Type X gypsum drywall is specifically engineered to meet fire-resistant building code requirements, offering a minimum of one-hour fire resistance and often carrying UL (Underwriters Laboratories) and ASTM E84 certifications. Type C gypsum includes enhanced core materials that provide superior fire ratings beyond Type X standards, commonly meeting or exceeding ASTM E119 and UL fire test classifications for walls and ceilings. Both types adhere to strict code regulations but Type C is preferred in high-risk fire zones due to its advanced certifications and higher thermal insulation performance.

Cost and Availability Analysis

Type X gypsum typically costs more than Type C gypsum due to its enhanced fire-resistant additives, making it a preferred choice for fire-rated wall systems. Type C gypsum, often considered standard drywall, is widely available and more affordable, suitable for non-fire-rated applications and general construction. Availability of Type X gypsum may be limited in some regions, potentially increasing lead times and prices compared to the more commonly stocked Type C gypsum.

Choosing the Right Gypsum Type for Your Project

Type X gypsum is specifically engineered for enhanced fire resistance, making it ideal for projects requiring strict compliance with fire safety codes, such as commercial buildings and multi-family residences. Type C gypsum offers superior fire protection compared to regular drywall but is less commonly used due to its higher cost and limited availability, often reserved for specialized applications needing additional fire rating. Selecting the appropriate gypsum type depends on project-specific fire resistance requirements, budget constraints, and local building codes to ensure safety without unnecessary expense.

Type X Gypsum vs Type C Gypsum Infographic

materialdif.com

materialdif.com