Grog and chamotte are both fired clay materials used to enhance the strength and thermal shock resistance of clay bodies. Grog is ground, fired clay that adds texture and reduces shrinkage during drying and firing, making it ideal for pottery and sculpture. Chamotte, a type of grog usually made from high-quality, refractory clays, offers superior heat resistance and is commonly used in ceramics requiring durability in high-temperature environments.

Table of Comparison

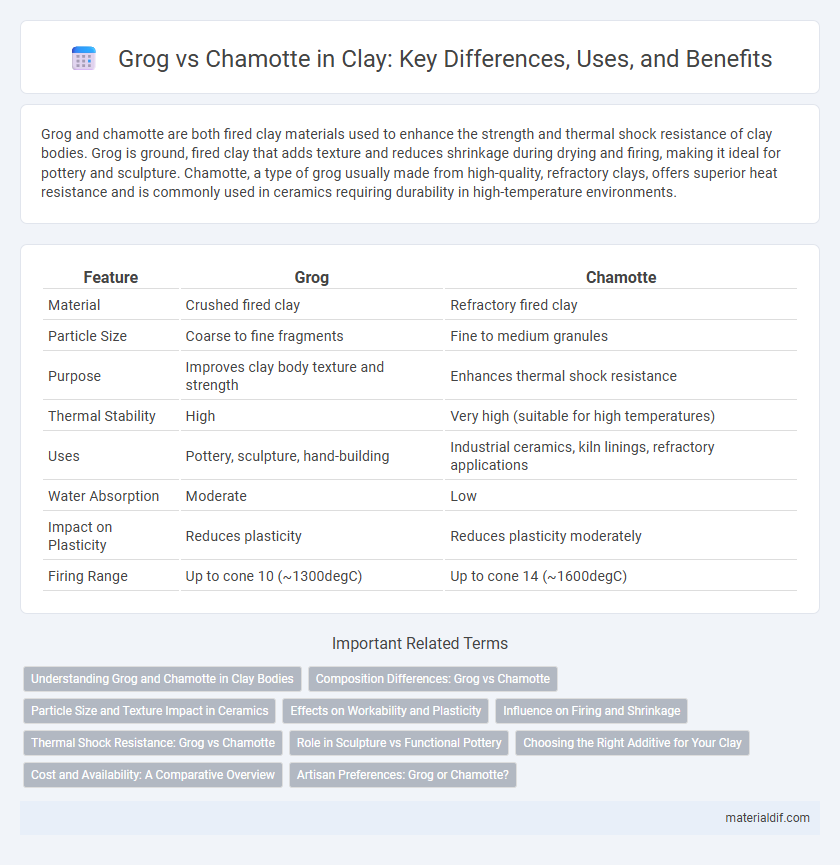

| Feature | Grog | Chamotte |

|---|---|---|

| Material | Crushed fired clay | Refractory fired clay |

| Particle Size | Coarse to fine fragments | Fine to medium granules |

| Purpose | Improves clay body texture and strength | Enhances thermal shock resistance |

| Thermal Stability | High | Very high (suitable for high temperatures) |

| Uses | Pottery, sculpture, hand-building | Industrial ceramics, kiln linings, refractory applications |

| Water Absorption | Moderate | Low |

| Impact on Plasticity | Reduces plasticity | Reduces plasticity moderately |

| Firing Range | Up to cone 10 (~1300degC) | Up to cone 14 (~1600degC) |

Understanding Grog and Chamotte in Clay Bodies

Grog and chamotte are both granular materials added to clay bodies to enhance strength, thermal resistance, and workability. Grog, fired and crushed clay, offers coarse particles that reduce shrinkage and improve drying, while chamotte specifically refers to finely ground fired clay with a more uniform texture, providing smoother surfaces and increased refractoriness. Selecting between grog and chamotte depends on the desired texture and firing temperature of the clay body, with grog suited for pottery needing added durability and chamotte ideal for ceramic sculpture and high-fire applications.

Composition Differences: Grog vs Chamotte

Grog is created from crushed, pre-fired clay particles, providing angular texture and improved thermal shock resistance, while chamotte consists primarily of finely ground fired clay rich in alumina and silica, offering superior strength and refractoriness. The key compositional difference lies in particle size and mineral content; grog retains more coarse inclusions, enhancing plasticity and workability, whereas chamotte's finer granules deliver higher durability and heat resistance. These distinctions influence clay body formulation, with grog preferred for structural support and chamotte chosen for high-temperature kiln furniture and refractory applications.

Particle Size and Texture Impact in Ceramics

Grog and chamotte differ primarily in particle size and texture, significantly influencing ceramic properties. Grog typically has coarser, irregular particles that enhance workability and strength by reducing shrinkage and cracking during firing. Chamotte consists of finer, more uniform particles that improve surface smoothness and detail retention in finished ceramic pieces.

Effects on Workability and Plasticity

Grog improves clay workability by reducing shrinkage and increasing thermal shock resistance, making it ideal for thinner, more intricate forms. Chamotte enhances plasticity and plastic deformation, enabling smoother shaping and greater flexibility in molding processes. Both additives modify texture, but grog reduces moisture content while chamotte retains it, influencing drying rates and final strength of ceramic pieces.

Influence on Firing and Shrinkage

Grog consists of pre-fired clay particles that reduce shrinkage and thermal expansion during firing, enhancing the structural integrity of ceramics. Chamotte, made from crushed fired clay, also minimizes shrinkage but offers coarser texture and improved thermal resistance for high-temperature firings. Both materials influence firing behavior by promoting even drying and reducing warping, but grog typically provides a finer, more consistent particle size for smoother ceramic surfaces.

Thermal Shock Resistance: Grog vs Chamotte

Grog provides superior thermal shock resistance compared to chamotte due to its pre-fired clay composition, which reduces shrinkage and cracking under rapid temperature changes. Chamotte, made from crushed firebrick, offers durability but is less effective in withstanding sudden thermal stress. Optimal use of grog enhances clay body performance in high-temperature applications such as kiln furniture and refractory linings.

Role in Sculpture vs Functional Pottery

Grog enhances clay's strength and thermal shock resistance, making it ideal for functional pottery subjected to high temperatures and frequent use. Chamotte, with its coarser texture, provides superior structural support and stability, preferred in sculptural works requiring intricate detail and durability. Both additives improve workability but target different outcomes: grog for utility and chamotte for artistic form.

Choosing the Right Additive for Your Clay

Grog and chamotte are both essential additives that improve clay's thermal resistance and reduce shrinkage during firing. Grog, made from ground pre-fired clay, enhances strength and porosity, making it ideal for wheel-thrown pottery and large sculptural pieces. Chamotte, a finer, refractory particle derived from crushed fireclay, offers superior heat resistance and texture control, preferred in kiln furniture and high-temperature ceramic work.

Cost and Availability: A Comparative Overview

Grog is typically more affordable and widely available due to its production from crushed fired clay, making it a preferred choice for cost-sensitive pottery and ceramics projects. Chamotte, sourced from high-quality refractory clays, tends to be pricier and less commonly stocked, often reserved for specialized applications requiring superior thermal resistance. Both materials enhance clay bodies' workability and durability but differ significantly in pricing and market accessibility.

Artisan Preferences: Grog or Chamotte?

Artisan potters often prefer grog for its ability to enhance clay body strength and reduce shrinkage, making it ideal for wheel throwing and hand-building techniques. Chamotte, valued for its finer particle size, is favored in sculptural work and delicate ceramics where texture and surface finish are critical. The choice between grog and chamotte ultimately depends on the artist's desired durability, texture, and firing temperature requirements.

Grog vs Chamotte Infographic

materialdif.com

materialdif.com