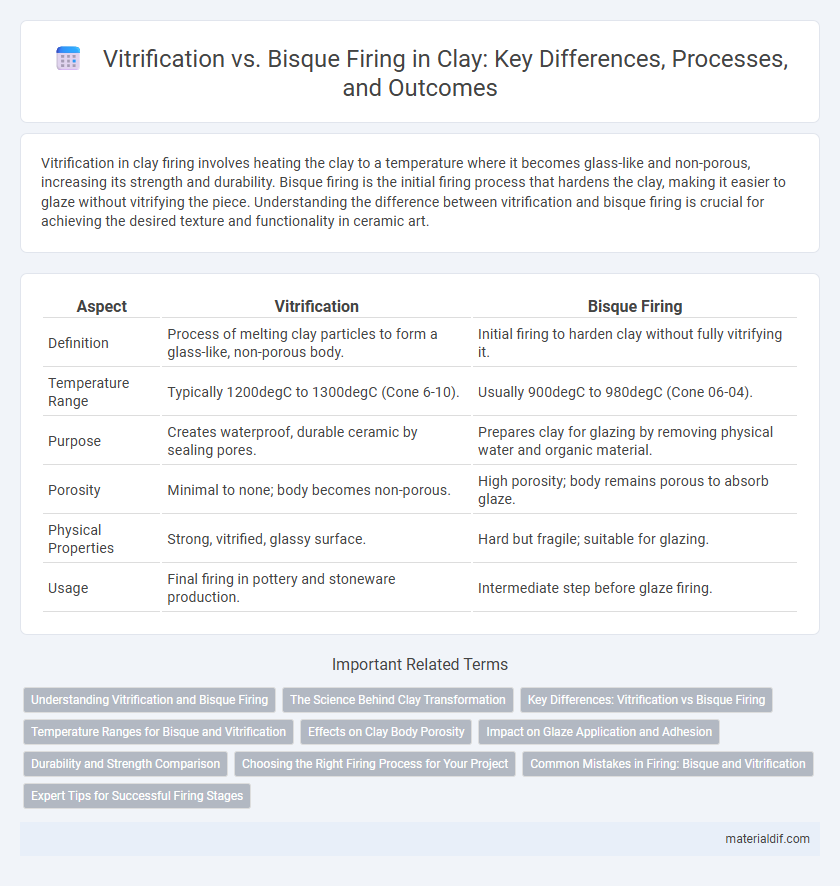

Vitrification in clay firing involves heating the clay to a temperature where it becomes glass-like and non-porous, increasing its strength and durability. Bisque firing is the initial firing process that hardens the clay, making it easier to glaze without vitrifying the piece. Understanding the difference between vitrification and bisque firing is crucial for achieving the desired texture and functionality in ceramic art.

Table of Comparison

| Aspect | Vitrification | Bisque Firing |

|---|---|---|

| Definition | Process of melting clay particles to form a glass-like, non-porous body. | Initial firing to harden clay without fully vitrifying it. |

| Temperature Range | Typically 1200degC to 1300degC (Cone 6-10). | Usually 900degC to 980degC (Cone 06-04). |

| Purpose | Creates waterproof, durable ceramic by sealing pores. | Prepares clay for glazing by removing physical water and organic material. |

| Porosity | Minimal to none; body becomes non-porous. | High porosity; body remains porous to absorb glaze. |

| Physical Properties | Strong, vitrified, glassy surface. | Hard but fragile; suitable for glazing. |

| Usage | Final firing in pottery and stoneware production. | Intermediate step before glaze firing. |

Understanding Vitrification and Bisque Firing

Vitrification in clay refers to the process where the clay body reaches a temperature high enough to become glass-like and non-porous, typically around 1,200degC to 1,300degC during glaze firing. Bisque firing occurs at lower temperatures, approximately 900degC to 1,000degC, to harden the clay while keeping it porous and absorbent for glazing. Understanding the distinction between vitrification and bisque firing is essential for controlling the durability and permeability of ceramic pieces in pottery and sculpture.

The Science Behind Clay Transformation

Vitrification in clay occurs when the material reaches high temperatures, causing silica particles to fuse and create a glass-like, non-porous surface that significantly enhances strength and durability. Bisque firing, conducted at lower temperatures, primarily drives off physical and chemical water without fully melting the clay body, leaving it porous and soft enough for glazing. The distinct temperature thresholds in vitrification and bisque firing fundamentally alter clay's molecular structure, transitioning it from a fragile state to one suited for functional or artistic purposes.

Key Differences: Vitrification vs Bisque Firing

Vitrification in clay refers to the process where the ceramic material becomes glass-like and non-porous due to high-temperature firing, typically above 1200degC, enhancing strength and watertightness. Bisque firing occurs at lower temperatures, usually between 900degC and 1000degC, aiming to harden the clay while maintaining its porous structure for glazing. Key differences include vitrification's role in final durability and impermeability compared to bisque firing's function in preparing pieces for glazing and decoration.

Temperature Ranges for Bisque and Vitrification

Bisque firing typically occurs between 1730degF and 1940degF (945degC to 1060degC), transforming clay into a porous and durable state ready for glazing. Vitrification happens at higher temperatures, often ranging from 2192degF to 2372degF (1200degC to 1300degC), where clay particles fuse to form a glass-like, non-porous surface. Understanding these temperature ranges is crucial for optimizing the strength, porosity, and final appearance of ceramic pieces.

Effects on Clay Body Porosity

Vitrification significantly reduces clay body porosity by causing the silica and fluxes to fuse into a glass-like surface, making the clay denser and less absorbent. Bisque firing, on the other hand, leaves the clay body porous and porous enough to absorb water, facilitating glaze application. The porous nature after bisque firing aids in glaze adhesion but does not enhance the strength or water resistance that results from vitrification.

Impact on Glaze Application and Adhesion

Vitrification creates a dense, non-porous clay body that requires glazing to achieve a smooth, often glossy surface, enhancing glaze adhesion and durability. Bisque firing results in a porous clay body that readily absorbs glaze, allowing for better mechanical bonding but requiring careful glaze application to avoid over-saturation or uneven coverage. The choice between vitrification and bisque firing directly affects glaze effectiveness, with vitrified surfaces demanding formulations that bond chemically, while bisque ware relies more on physical adhesion.

Durability and Strength Comparison

Vitrification significantly enhances the durability and strength of clay by transforming it into a glass-like, non-porous material through high-temperature firing, making it ideal for functional pottery and structural ceramics. Bisque firing, performed at lower temperatures, leaves the clay porous and more fragile, suitable mainly for glazing and handling before final firing. The vitrification process results in increased mechanical strength and water resistance, whereas bisque-fired clay remains susceptible to chipping and absorption.

Choosing the Right Firing Process for Your Project

Selecting between vitrification and bisque firing depends on the clay body's purpose and desired durability; vitrification achieves a glass-like, non-porous surface ideal for functional ceramics, while bisque firing hardens the clay to a porous state suitable for glazing. Vitrification occurs at high temperatures, typically above 1200degC, causing clay particles to fuse and increase strength, whereas bisque firing is a lower temperature process around 900-1000degC that prepares the piece for glazing. Choosing the right firing process hinges on the final use, design requirements, and clay composition to ensure optimal performance and aesthetic results.

Common Mistakes in Firing: Bisque and Vitrification

Common mistakes in bisque firing include under-firing clay, resulting in fragile, porous pots prone to chipping, or over-firing, which can cause warping and loss of surface detail. During vitrification, failing to reach the correct temperature range leads to insufficient melting of clay particles, producing weak, non-waterproof ceramics or excessive melting that can deform the ware. Accurate temperature control and understanding the clay body's maturation point are essential to avoid these firing errors and achieve durable, vitrified pottery.

Expert Tips for Successful Firing Stages

Vitrification marks the stage where clay transforms into a glass-like, non-porous state, achieved at higher kiln temperatures between 1,200degC and 1,400degC depending on the clay body. Bisque firing, typically conducted at 900degC to 1,000degC, hardens the clay without full vitrification, allowing for easier glazing and handling. Experts recommend slow temperature ramps and consistent kiln atmosphere control during bisque firing to prevent cracking, while precise temperature holds during vitrification ensure optimal strength and durability of the final ceramic piece.

Vitrification vs Bisque Firing Infographic

materialdif.com

materialdif.com