Coil construction in clay pets involves rolling long, snake-like coils of clay and stacking them to build the form, which offers greater flexibility for organic shapes and texture variations. Slab construction uses flat, rolled-out sheets of clay that are cut and joined together, providing a more uniform surface and structural stability. Each method impacts the final piece's aesthetic and strength, influencing the artist's choice based on desired detail and durability.

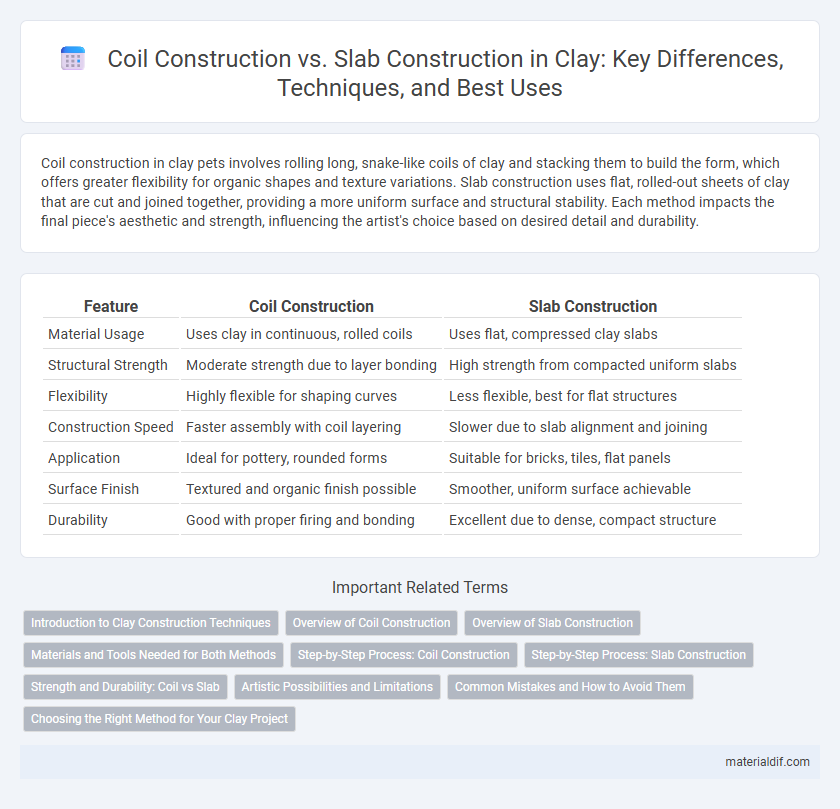

Table of Comparison

| Feature | Coil Construction | Slab Construction |

|---|---|---|

| Material Usage | Uses clay in continuous, rolled coils | Uses flat, compressed clay slabs |

| Structural Strength | Moderate strength due to layer bonding | High strength from compacted uniform slabs |

| Flexibility | Highly flexible for shaping curves | Less flexible, best for flat structures |

| Construction Speed | Faster assembly with coil layering | Slower due to slab alignment and joining |

| Application | Ideal for pottery, rounded forms | Suitable for bricks, tiles, flat panels |

| Surface Finish | Textured and organic finish possible | Smoother, uniform surface achievable |

| Durability | Good with proper firing and bonding | Excellent due to dense, compact structure |

Introduction to Clay Construction Techniques

Coil construction in clay involves rolling long, snake-like strands of clay and stacking them to build walls, allowing for organic shapes and strong structural integrity. Slab construction uses flat, rolled-out sheets of clay joined together, offering uniform thickness and precise geometric forms. Both techniques require skillful joining methods like scoring and slip application to ensure durability and prevent cracking during drying and firing.

Overview of Coil Construction

Coil construction is a pottery technique characterized by building forms using long, rolled strips of clay layered and smoothed to create walls. This method offers flexibility in shaping complex and large-scale ceramic pieces, allowing for gradual height and thickness adjustments during the construction process. The tactile nature of coil construction also promotes strong structural integrity and artistic control over surface texture and form.

Overview of Slab Construction

Slab construction involves pouring concrete directly onto a prepared ground surface, creating a flat, stable base often reinforced with steel rebar for increased strength and durability. This method is particularly effective for clay-rich soils, where consistent moisture levels help prevent cracking and shifting caused by soil expansion and contraction. Its cost-efficiency, speed of installation, and resistance to termite damage make slab construction a preferred choice for many residential and commercial buildings on clay substrates.

Materials and Tools Needed for Both Methods

Coil construction requires clay coils, a potter's wheel or shaping tools, and slip for joining coils securely, while slab construction demands clay slabs, a rolling pin or slab roller, and scoring tools to ensure proper adhesion between slabs. Both methods benefit from wire cutters for removing clay pieces and sponges for smoothing surfaces and maintaining moisture. Understanding the specific materials and tools for each technique optimizes the crafting process and enhances the structural integrity of the clay work.

Step-by-Step Process: Coil Construction

Coil construction in clay involves rolling out long, snake-like ropes of clay and stacking them progressively to build the vessel's walls, ensuring even thickness and structural integrity. Each coil layer is carefully smoothed and joined using scoring and slipping techniques to prevent cracks and maintain cohesion during drying and firing. This method allows for greater control over shape and size, making it ideal for creating organic, rounded forms and intricate designs.

Step-by-Step Process: Slab Construction

Slab construction involves spreading a wet clay mixture onto a flat surface, then smoothing and layering it for uniform thickness. The process begins with preparing the clay to a workable consistency, followed by rolling or patting it out evenly into slabs. Once the slabs are formed, they are cut to desired shapes and joined by scoring and slip application before drying and firing.

Strength and Durability: Coil vs Slab

Coil construction in clay pottery involves building the vessel with rolled clay ropes, resulting in enhanced structural flexibility and the ability to create thicker walls, which improves overall durability under stress. Slab construction uses flat, rolled sheets of clay joined together, providing uniform strength and a smooth surface but typically less resilience to bending or impact compared to coil-built pieces. Coil-built ceramics generally exhibit superior strength in curved forms, while slab construction offers consistent flat-panel rigidity, influencing the choice based on the intended use and mechanical demands.

Artistic Possibilities and Limitations

Coil construction in clay allows for intricate textures and organic shapes, enabling artists to build tall, hollow forms with detailed surface patterns, which enhances creative expression and structural flexibility. Slab construction offers broad, flat surfaces suitable for geometric designs and precise angles, promoting versatility in architectural and sculptural projects but limiting rounded or freeform shapes. Both techniques influence artistic possibilities by balancing structural stability and the complexity of form achievable in ceramic art.

Common Mistakes and How to Avoid Them

Common mistakes in coil construction include uneven coil thickness and poor joining between coils, leading to weak spots and cracks; careful smoothing and consistent coil dimensions can prevent these issues. In slab construction, improper wedging and uneven slab thickness often cause warping and cracking, so thorough wedging and uniform slab preparation are essential. Avoiding contamination and ensuring even drying times are crucial in both methods to maintain structural integrity and avoid defects.

Choosing the Right Method for Your Clay Project

Coil construction offers greater flexibility for creating organic shapes and detailed textures in clay projects, making it ideal for hand-building techniques. Slab construction provides uniform thickness and strong structural integrity, perfect for precise, flat surfaces and geometric designs. Selecting the right method depends on the intended form, scale, and functional requirements of your clay piece.

Coil Construction vs Slab Construction Infographic

materialdif.com

materialdif.com