Raku firing involves rapid heating and cooling of clay pieces, producing crackled glaze surfaces and smoky effects, while sagger firing encloses the pottery in a container with combustible materials that create unique smoke patterns and color variations. Raku firing is often done outdoors with immediate removal from the kiln, enhancing thermal shock effects, whereas sagger firing allows for controlled environments that influence surface textures through atmospheric interactions. Both methods offer distinct artistic expressions, with raku emphasizing dramatic glaze finishes and sagger highlighting subtle, organic surface alterations.

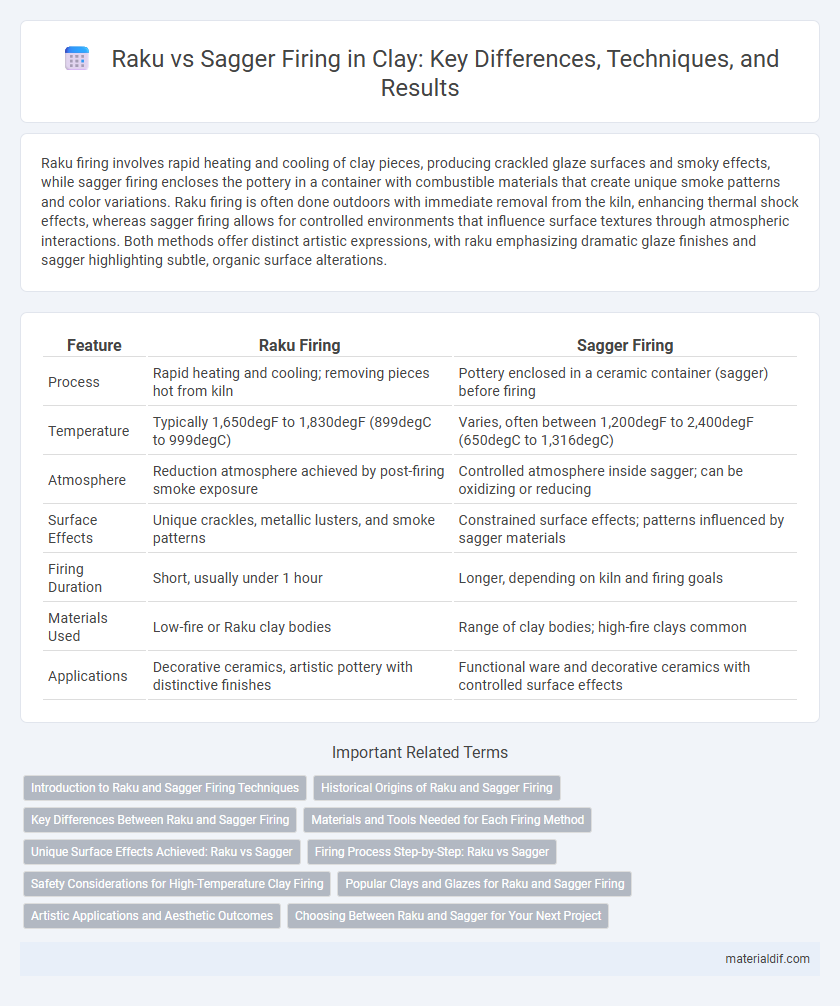

Table of Comparison

| Feature | Raku Firing | Sagger Firing |

|---|---|---|

| Process | Rapid heating and cooling; removing pieces hot from kiln | Pottery enclosed in a ceramic container (sagger) before firing |

| Temperature | Typically 1,650degF to 1,830degF (899degC to 999degC) | Varies, often between 1,200degF to 2,400degF (650degC to 1,316degC) |

| Atmosphere | Reduction atmosphere achieved by post-firing smoke exposure | Controlled atmosphere inside sagger; can be oxidizing or reducing |

| Surface Effects | Unique crackles, metallic lusters, and smoke patterns | Constrained surface effects; patterns influenced by sagger materials |

| Firing Duration | Short, usually under 1 hour | Longer, depending on kiln and firing goals |

| Materials Used | Low-fire or Raku clay bodies | Range of clay bodies; high-fire clays common |

| Applications | Decorative ceramics, artistic pottery with distinctive finishes | Functional ware and decorative ceramics with controlled surface effects |

Introduction to Raku and Sagger Firing Techniques

Raku firing is a rapid ceramic firing process originating from Japan, characterized by removing pottery from the kiln while red-hot and cooling it quickly in the open air or combustible materials, resulting in unique surface textures and crackles. Sagger firing involves enclosing clay pieces within a protective container or sagger, shielding them from direct flame and ash, which allows for controlled oxidation and reduction atmospheres to produce varied surface effects. Both techniques emphasize the interaction of heat and atmosphere to create distinctive finishes, appealing to artists seeking creative experimentation in ceramic glazing and texture.

Historical Origins of Raku and Sagger Firing

Raku firing originated in 16th-century Japan, closely tied to the tea ceremony and renowned for its rapid firing and cooling process, which produces unique surface textures and crackled glazes. Sagger firing dates back to ancient civilizations, using clay containers to shield pottery from direct flame and ash, preserving the ware while enabling oxidation or reduction atmospheres to influence surface effects. These distinct historical origins highlight Raku's cultural significance in Japanese artistry and Sagger firing's practical role in early ceramic technology worldwide.

Key Differences Between Raku and Sagger Firing

Raku firing involves rapid heating and cooling, allowing potters to remove pieces while red-hot for unique surface effects and crackling, whereas sagger firing encloses pottery within a protective container to control atmosphere and reduce direct flame contact. Raku typically results in unpredictable, metallic surfaces due to reduction atmospheres, while sagger firing produces more controlled, subtle color variations by limiting oxygen exposure. The techniques differ in firing duration, temperature ranges, and post-firing treatments, with raku favoring immediate cooling and sagger favoring longer, slower cooling phases.

Materials and Tools Needed for Each Firing Method

Raku firing requires raku clay, which is low in grog and designed to withstand rapid thermal shock, along with specialized raku glazes that crackle during cooling. Essential tools include a raku kiln capable of reaching high temperatures quickly, tongs for handling hot pieces, and a reduction vessel filled with combustible materials like sawdust or newspaper to create unique surface effects. In contrast, sagger firing involves using a sagger--a protective container made from refractory clay or firebrick--to encase ceramic pieces, protecting them from direct flame and ash, with materials often including organic matter or metal oxides inside the sagger to influence surface coloration.

Unique Surface Effects Achieved: Raku vs Sagger

Raku firing produces unpredictable crackles, metallic lusters, and smoky textures through rapid cooling and post-firing reduction, creating organic and spontaneous surface effects. Sagger firing encapsulates clay pieces in containers packed with combustible materials, resulting in controlled carbonization, ash deposits, and subtle color variations unique to the materials enclosed. Both methods manipulate atmosphere and heat, but Raku emphasizes dramatic, immediate surface transformations while Sagger achieves more nuanced, layered textures.

Firing Process Step-by-Step: Raku vs Sagger

Raku firing involves removing the pottery from the kiln at high temperatures (about 1,650degF or 900degC) and placing it into combustible materials such as sawdust or newspaper, creating a reduction atmosphere that results in unique glaze effects. Sagger firing requires enclosing pots in a protective container called a sagger before placing them in the kiln, allowing for higher temperatures (up to 2,300degF or 1,260degC) and more controlled exposure to flames and smoke, which imparts distinct surface textures and colors. The key difference lies in Raku's rapid cooling and direct interaction with combustibles outside the kiln, versus Sagger's prolonged exposure within a controlled environment inside the kiln.

Safety Considerations for High-Temperature Clay Firing

Raku firing involves rapid heating and cooling, exposing potters to thermal shock and toxic fumes from combustible materials, requiring proper ventilation and protective gear. Sagger firing, which encloses clay pieces in ceramic containers within a kiln, minimizes direct flame exposure but still demands heat-resistant gloves and careful handling to prevent burns. Both methods necessitate training in kiln operation, fire-resistant clothing, and strict adherence to safety protocols to mitigate risks during high-temperature clay firing.

Popular Clays and Glazes for Raku and Sagger Firing

Raku firing typically uses low-fire clays such as earthenware and terra cotta that withstand thermal shock, paired with metallic or crackle glazes like copper or manganese to achieve vibrant, unpredictable finishes. Sagger firing allows a broader range of clays including stoneware and porcelain due to the protective sagger container, facilitating higher firing temperatures and promoting subtle, atmospheric glaze effects from natural ash or carbon deposits. Popular glazes for sagger firing include ash glazes and celadons, which develop unique textures and colors influenced by the smoky, reduction atmosphere inside the sagger.

Artistic Applications and Aesthetic Outcomes

Raku firing produces unique crackled glazes and metallic finishes that emphasize spontaneity and texture, making it ideal for expressive and bold artistic applications. Sagger firing allows for controlled atmosphere effects and subtle surface textures by enclosing the clay in a protective container, resulting in earthy, organic aesthetics with muted color variations. Artists often choose raku for striking, unpredictable results, while sagger firing is favored for refined, nuanced finishes that highlight natural materials.

Choosing Between Raku and Sagger for Your Next Project

Choosing between Raku and Sagger firing depends on the desired surface effects and firing atmosphere. Raku firing produces unique crackle glazes and smoky textures through rapid cooling, ideal for expressive, one-of-a-kind pieces. Sagger firing offers controlled environments that protect the clay from direct flame while allowing specific decorative effects, making it suitable for more refined and predictable finishes.

Raku vs Sagger Firing Infographic

materialdif.com

materialdif.com