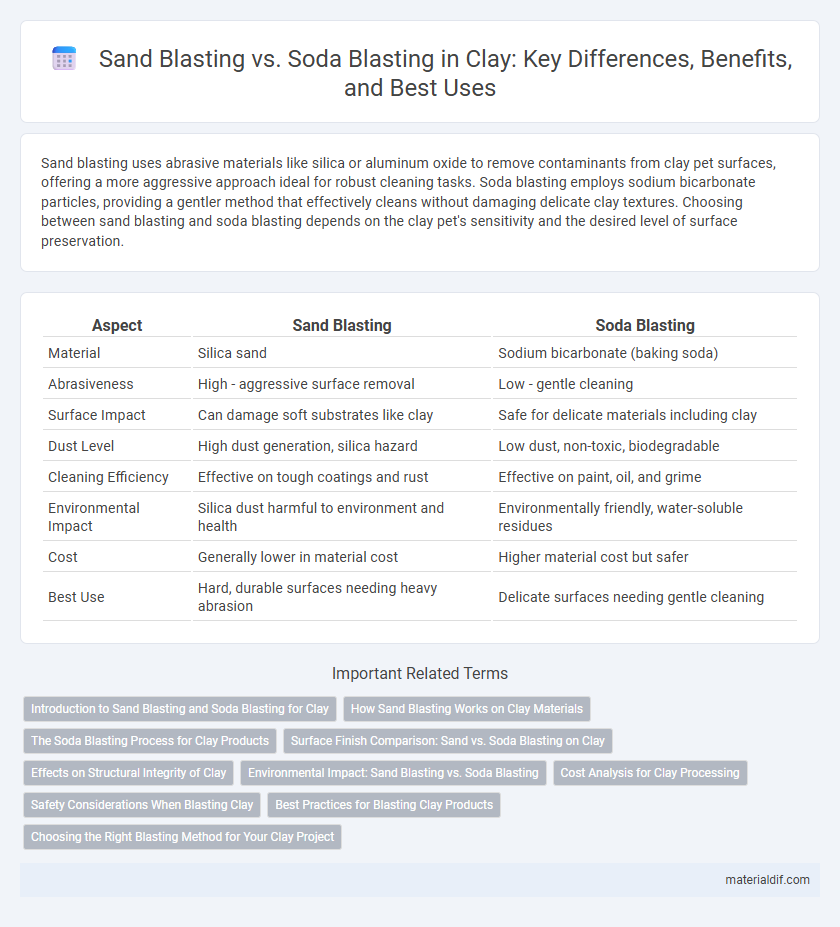

Sand blasting uses abrasive materials like silica or aluminum oxide to remove contaminants from clay pet surfaces, offering a more aggressive approach ideal for robust cleaning tasks. Soda blasting employs sodium bicarbonate particles, providing a gentler method that effectively cleans without damaging delicate clay textures. Choosing between sand blasting and soda blasting depends on the clay pet's sensitivity and the desired level of surface preservation.

Table of Comparison

| Aspect | Sand Blasting | Soda Blasting |

|---|---|---|

| Material | Silica sand | Sodium bicarbonate (baking soda) |

| Abrasiveness | High - aggressive surface removal | Low - gentle cleaning |

| Surface Impact | Can damage soft substrates like clay | Safe for delicate materials including clay |

| Dust Level | High dust generation, silica hazard | Low dust, non-toxic, biodegradable |

| Cleaning Efficiency | Effective on tough coatings and rust | Effective on paint, oil, and grime |

| Environmental Impact | Silica dust harmful to environment and health | Environmentally friendly, water-soluble residues |

| Cost | Generally lower in material cost | Higher material cost but safer |

| Best Use | Hard, durable surfaces needing heavy abrasion | Delicate surfaces needing gentle cleaning |

Introduction to Sand Blasting and Soda Blasting for Clay

Sand blasting uses high-pressure air to force abrasive sand particles onto clay surfaces, effectively smoothing or shaping the material by removing unwanted layers or textures. Soda blasting employs sodium bicarbonate particles propelled at lower pressure, providing a gentler cleaning method ideal for delicate clay pieces without causing surface damage. Both techniques offer unique advantages for refining clay artwork, with sand blasting suited for robust surface modification and soda blasting preferred for precision cleaning and restoration.

How Sand Blasting Works on Clay Materials

Sand blasting works on clay materials by propelling fine abrasive sand particles at high velocity to remove surface impurities, old glaze, and residues. This process effectively smooths and cleans the porous surface of clay, enhancing texture and preparing it for painting or glazing. The abrasive action also helps to expose underlying layers, improving adhesion for subsequent treatments.

The Soda Blasting Process for Clay Products

The soda blasting process for clay products involves using sodium bicarbonate particles propelled at high velocity to gently clean surfaces without causing damage. This method effectively removes contaminants, glazes, and residues from clay items while preserving the material's integrity and texture. Soda blasting is preferred over sand blasting for delicate clay due to its non-abrasive nature and environmentally friendly, biodegradable media.

Surface Finish Comparison: Sand vs. Soda Blasting on Clay

Sand blasting creates a rougher surface finish on clay, enhancing adhesion for coatings but risking surface damage due to its abrasive nature. Soda blasting produces a smoother, more uniform finish that gently cleans clay surfaces without erosion, preserving fine details. For delicate clay works, soda blasting is preferred to maintain integrity, while sand blasting suits more robust pieces needing strong surface texture.

Effects on Structural Integrity of Clay

Sand blasting aggressively erodes the surface of clay, leading to micro-cracks and compromising the clay's structural integrity over time. Soda blasting uses sodium bicarbonate particles, which are softer and more gentle, preserving the clay's strength and reducing the risk of damage. Choosing soda blasting minimizes surface deterioration and maintains the clay's original texture and durability.

Environmental Impact: Sand Blasting vs. Soda Blasting

Sand blasting generates significant dust containing silica particles, posing health risks and contributing to environmental pollution, whereas soda blasting uses baking soda, which is non-toxic and biodegradable, making it a safer choice for the environment. Soda blasting produces less airborne particulate matter and avoids contaminating soil or water sources with hazardous materials commonly associated with sand blasting. The reduced environmental impact and safer disposal requirements of soda blasting make it a preferred method for eco-conscious clay restoration and cleaning projects.

Cost Analysis for Clay Processing

Sand blasting incurs higher operational costs due to abrasive grit replacement and increased equipment wear when processing clay materials. Soda blasting offers a more cost-effective alternative with lower abrasive consumption and less equipment maintenance, making it suitable for delicate clay surfaces. The difference in media disposal fees and environmental compliance considerations also impacts the overall expense of each method in clay processing.

Safety Considerations When Blasting Clay

Sand blasting clay involves silica dust exposure, posing significant respiratory hazards and requiring extensive protective equipment such as respirators and ventilation systems. Soda blasting emits less harmful dust and is considered safer for operators handling clay, though eye protection and gloves remain essential to prevent irritation. Proper containment and cleanup practices are critical in both methods to minimize airborne particles and ensure worker safety during clay surface preparation.

Best Practices for Blasting Clay Products

Sand blasting effectively removes surface impurities from clay products but can be too abrasive, risking damage to delicate details. Soda blasting uses sodium bicarbonate particles, offering a gentler alternative that preserves fine textures and reduces surface erosion during cleaning. Best practices involve selecting soda blasting for fragile clay pieces and controlling pressure settings to avoid material degradation.

Choosing the Right Blasting Method for Your Clay Project

Selecting the appropriate blasting method for your clay project depends on the material's fragility and desired finish, with sand blasting offering aggressive abrasion suitable for hard, durable clay surfaces. Soda blasting provides a gentler cleaning process using sodium bicarbonate, ideal for delicate clay pieces requiring surface preservation and minimal erosion. Understanding the clay's hardness and project goals ensures optimal removal of impurities without compromising structural integrity.

Sand Blasting vs Soda Blasting Infographic

materialdif.com

materialdif.com