Terracotta clay is porous, ideal for plants needing good drainage and aeration, while porcellaneous clay is dense and non-porous, offering a sleek finish and enhanced durability. Terracotta pots absorb moisture and can help regulate soil humidity, whereas porcellaneous pots retain water more effectively, benefiting moisture-loving plants. Choosing between the two depends on the plant's watering needs and the aesthetic preferences for your garden.

Table of Comparison

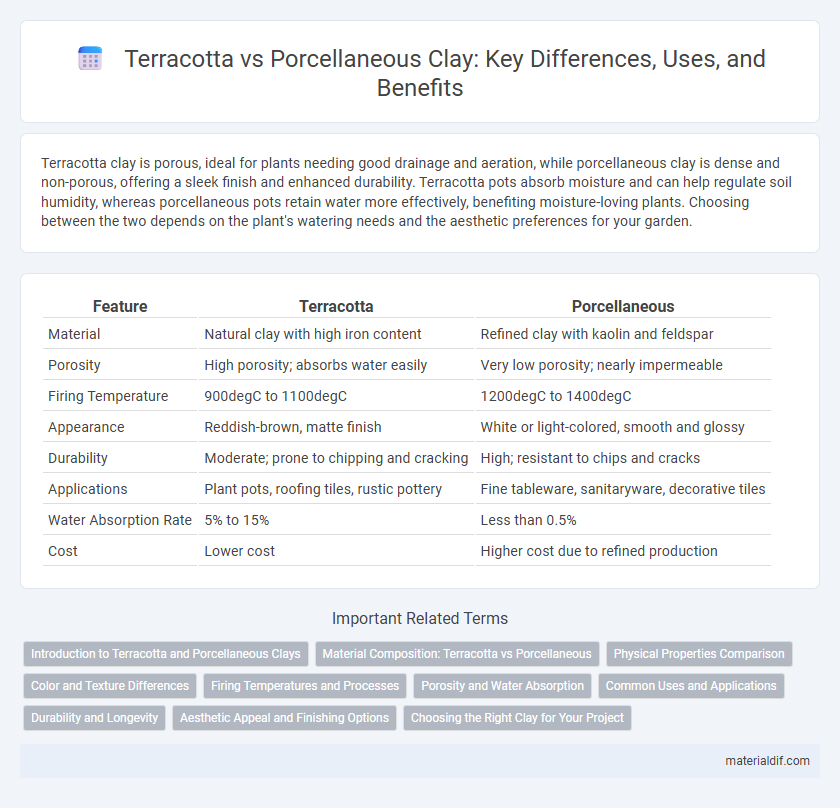

| Feature | Terracotta | Porcellaneous |

|---|---|---|

| Material | Natural clay with high iron content | Refined clay with kaolin and feldspar |

| Porosity | High porosity; absorbs water easily | Very low porosity; nearly impermeable |

| Firing Temperature | 900degC to 1100degC | 1200degC to 1400degC |

| Appearance | Reddish-brown, matte finish | White or light-colored, smooth and glossy |

| Durability | Moderate; prone to chipping and cracking | High; resistant to chips and cracks |

| Applications | Plant pots, roofing tiles, rustic pottery | Fine tableware, sanitaryware, decorative tiles |

| Water Absorption Rate | 5% to 15% | Less than 0.5% |

| Cost | Lower cost | Higher cost due to refined production |

Introduction to Terracotta and Porcellaneous Clays

Terracotta clay is a porous, low-fired ceramic material known for its rich reddish-brown color and rustic texture, commonly used in pottery, tiles, and sculptures. Porcellaneous clay, in contrast, is a dense, high-fired clay that vitrifies at higher temperatures, producing a smooth, white, and non-porous surface ideal for fine porcelain and high-quality ceramics. Understanding these fundamental differences in firing temperature, porosity, and appearance helps artists and manufacturers select the appropriate clay type for functional and decorative purposes.

Material Composition: Terracotta vs Porcellaneous

Terracotta is composed primarily of natural clay with iron content, giving it a porous texture and reddish-brown color, while porcellaneous material is made from refined kaolin clay mixed with feldspar and quartz, resulting in a dense, non-porous structure. Terracotta typically undergoes low-temperature firing around 1000degC, leading to its characteristic porous surface, whereas porcellaneous ceramics are fired at higher temperatures above 1200degC, enhancing their strength and translucency. The distinct mineral composition and firing processes define terracotta's rustic, breathable quality versus porcellaneous's smooth, durable finish.

Physical Properties Comparison

Terracotta, characterized by its porous and coarse texture, exhibits lower density and greater water absorption compared to the dense, non-porous porcellaneous clay, which offers superior strength and vitrification. The physical properties of terracotta make it more breathable but less durable and prone to chipping, whereas porcellaneous clay's compact structure provides enhanced hardness, resistance to moisture, and a smooth finish. These differences impact their respective uses, with terracotta favored for rustic, decorative pottery and porcellaneous clay preferred for fine, high-quality ceramics requiring durability.

Color and Texture Differences

Terracotta clay exhibits warm, earthy tones ranging from reddish-brown to orange, featuring a porous, slightly rough texture ideal for rustic pottery and sculptures. In contrast, porcellaneous clay boasts a smooth, fine texture with a dense, glass-like surface, typically presenting in white or light cream colors that suit delicate, refined ceramic pieces. The color variability in terracotta results from iron content, while the purity and firing temperature primarily influence the consistent pale hue of porcellaneous clay.

Firing Temperatures and Processes

Terracotta is fired at lower temperatures typically between 1000degC and 1150degC, resulting in a porous and softer ceramic body that remains somewhat permeable to water. Porcellaneous clay undergoes firing at much higher temperatures, usually between 1200degC and 1400degC, causing vitrification that produces a dense, non-porous, and highly durable surface. The extended high-temperature firing process of porcellaneous clay transforms its microstructure, making it ideal for fine tableware and sanitary ware compared to the more rustic and breathable terracotta pottery.

Porosity and Water Absorption

Porcellaneous clay features a dense, non-porous structure with extremely low water absorption rates typically below 0.5%, making it highly impervious to moisture. In contrast, terracotta clay is porous with water absorption rates ranging from 5% to 15%, allowing it to retain more water and making it more susceptible to damage from freeze-thaw cycles. The low porosity of porcellaneous clay contributes to its durability and suitability for fine ceramics requiring a smooth, vitreous surface.

Common Uses and Applications

Terracotta is frequently used in garden pots, roof tiles, and artisanal pottery due to its porous nature and warm reddish color, making it ideal for decorative and functional outdoor items. Porcellaneous clay, known for its dense, non-porous, and durable quality, is preferred in fine tableware, sanitaryware, and high-quality ceramic tiles where strength and water resistance are essential. Both materials serve distinct purposes: terracotta excels in rustic, breathable products, while porcellaneous clay meets demands for sleek, durable, and water-tight ceramic goods.

Durability and Longevity

Terracotta is a porous, low-fired clay material that is less durable and more susceptible to chipping and moisture damage compared to porcellaneous clay. Porcellaneous, a highly vitrified and dense clay body fired at higher temperatures, offers superior durability and longevity, making it ideal for both functional and decorative applications. Its resistance to wear, water absorption, and thermal shock significantly extends the lifespan of products made from porcellaneous clay.

Aesthetic Appeal and Finishing Options

Terracotta offers a warm, rustic aesthetic with natural earthy tones and a matte finish, making it ideal for traditional and artisanal designs. Porcellaneous clay provides a sleek, polished surface with high translucency and a wide range of glazing options, enhancing its suitability for contemporary and refined aesthetics. The finishing options for terracotta emphasize natural textures, while porcellaneous allows for precise, smooth finishes and vibrant color applications.

Choosing the Right Clay for Your Project

Terracotta clay, known for its porous, reddish-orange composition, is ideal for rustic pottery and garden sculptures requiring breathability and natural aesthetics. Porcellaneous clay, with its fine, dense, and white vitrified body, suits high-quality ceramics demanding durability, smooth finishes, and resistance to moisture. Selecting between terracotta and porcellaneous clay depends on project requirements such as strength, water absorption, firing temperature, and desired texture.

Terracotta vs Porcellaneous Infographic

materialdif.com

materialdif.com