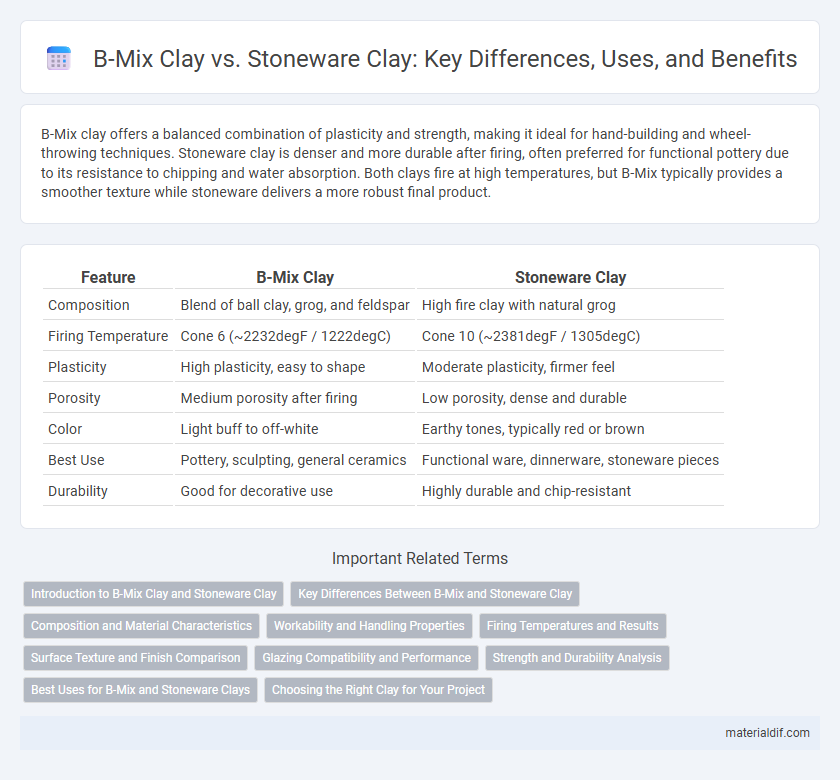

B-Mix clay offers a balanced combination of plasticity and strength, making it ideal for hand-building and wheel-throwing techniques. Stoneware clay is denser and more durable after firing, often preferred for functional pottery due to its resistance to chipping and water absorption. Both clays fire at high temperatures, but B-Mix typically provides a smoother texture while stoneware delivers a more robust final product.

Table of Comparison

| Feature | B-Mix Clay | Stoneware Clay |

|---|---|---|

| Composition | Blend of ball clay, grog, and feldspar | High fire clay with natural grog |

| Firing Temperature | Cone 6 (~2232degF / 1222degC) | Cone 10 (~2381degF / 1305degC) |

| Plasticity | High plasticity, easy to shape | Moderate plasticity, firmer feel |

| Porosity | Medium porosity after firing | Low porosity, dense and durable |

| Color | Light buff to off-white | Earthy tones, typically red or brown |

| Best Use | Pottery, sculpting, general ceramics | Functional ware, dinnerware, stoneware pieces |

| Durability | Good for decorative use | Highly durable and chip-resistant |

Introduction to B-Mix Clay and Stoneware Clay

B-Mix clay is a versatile, plastic-bodied clay that combines ball clay, fire clay, and silica, making it ideal for throwing and hand-building due to its smooth texture and high plasticity. Stoneware clay, known for its durability and vitrification at cone 5-10, contains a higher amount of feldspar and kaolin, resulting in a dense, non-porous body suitable for functional pottery. Both clays differ in firing temperature and texture, with B-Mix often preferred for beginner potters and stoneware favored for its strength and water resistance after firing.

Key Differences Between B-Mix and Stoneware Clay

B-Mix clay is a commercial blend known for its consistent plasticity and smooth texture, making it ideal for handbuilding and wheel throwing, while stoneware clay is a natural material that fires to a dense, durable, and vitrified state, suitable for functional pottery. B-Mix typically contains a mix of ball clay, kaolin, and other minerals to enhance workability, whereas stoneware clay varies in composition but generally includes higher amounts of feldspar and silica for strength and high firing temperatures. The firing range of B-Mix is usually lower than stoneware, with B-Mix firing around cone 6 (2232degF) and stoneware commonly fired from cone 5 to cone 10 (2167degF-2345degF), impacting the final hardness and porosity of the ceramic piece.

Composition and Material Characteristics

B-Mix clay is a balanced combination of ball clay, fire clay, and sometimes grog, offering moderate plasticity and strength, making it versatile for both hand-building and wheel-throwing. Stoneware clay contains higher amounts of kaolin and feldspar, resulting in a denser, more vitrified body after firing, typically at higher temperatures. The composition differences lead to B-Mix having better workability and drying qualities, while stoneware clay exhibits superior durability and water resistance upon firing.

Workability and Handling Properties

B-Mix clay offers superior workability due to its balanced particle size and plasticity, making it ideal for detailed hand-building and sculpting tasks. Stoneware clay, with its coarser texture and higher grog content, provides a more rigid handling experience suited for wheel throwing and structural pieces. The choice between B-Mix and stoneware clay depends largely on the artist's preference for smooth shaping versus robust support during firing.

Firing Temperatures and Results

B-Mix clay typically fires at lower temperatures around cone 06 to cone 04 (1828degF to 1940degF), resulting in a durable, slightly porous ceramic ideal for functional pottery and sculpture. Stoneware clay requires higher firing temperatures between cone 5 and cone 10 (2167degF to 2345degF), producing a vitrified, non-porous body with increased strength and water resistance. These firing temperature differences significantly impact the final texture, durability, and usability of the ceramic pieces made from each clay type.

Surface Texture and Finish Comparison

B-Mix clay offers a finer, smoother surface texture ideal for detailed work and a polished finish, while stoneware clay typically exhibits a coarser texture with more natural variation, resulting in a rustic, matte finish. The finer particle size of B-Mix allows for a more refined, uniform appearance, enhancing glaze adherence and vibrancy. Stoneware's robust composition provides durability and a textured aesthetic, often favored for functional pottery with a tactile, organic feel.

Glazing Compatibility and Performance

B-Mix clay offers excellent glazing compatibility due to its balanced mix of ball clay, kaolin, and feldspar, resulting in a smooth, vitrified surface that enhances glaze adherence and visual quality. Stoneware clay is known for its durability and firing range, providing a sturdy base that supports a wide variety of glaze types without crazing or peeling, making it ideal for functional pottery. Both clays perform well under high temperatures, but B-Mix tends to produce a finer texture ideal for detailed glazing, while stoneware offers greater strength and chip resistance after glazing.

Strength and Durability Analysis

B-Mix clay offers superior strength and durability compared to stoneware clay due to its optimized blend of plasticity and grog content, enhancing resistance to cracking and warping. Stoneware clay, while also durable, typically exhibits higher porosity, reducing its firmness under high-impact or thermal stress conditions. The reinforced particle structure in B-Mix clay makes it ideal for functional pottery requiring both robustness and longevity.

Best Uses for B-Mix and Stoneware Clays

B-Mix clay is ideal for beginners and hand-building projects due to its smooth texture and low shrinkage, making it perfect for pottery, sculpting, and decorative ceramics. Stoneware clay, known for its durability and versatility, excels in functional ware such as dinnerware, vases, and tiles that require high firing temperatures and strength. Choosing between B-Mix and stoneware clay depends on the intended use, with B-Mix favored for ease of use and stoneware preferred for resilience and longevity.

Choosing the Right Clay for Your Project

B-Mix Clay offers a balanced blend of plasticity and strength, making it ideal for hand-building and sculptural projects requiring intricate details. Stoneware Clay provides durability and a slightly rougher texture, suited for functional ceramics like dinnerware and pottery that withstand daily use. Selecting the right clay depends on your project's purpose, desired texture, firing temperature, and finish preferences to ensure optimal results.

B-Mix Clay vs Stoneware Clay Infographic

materialdif.com

materialdif.com