Glaze fit refers to how well the glaze adheres to the clay body without cracking or crazing during firing, ensuring durability and aesthetic appeal. The clay body composition, including its thermal expansion rate, must complement the glaze to prevent stress and defects in the finished piece. Achieving the ideal balance between glaze fit and clay body is crucial for functional and visually pleasing ceramic creations.

Table of Comparison

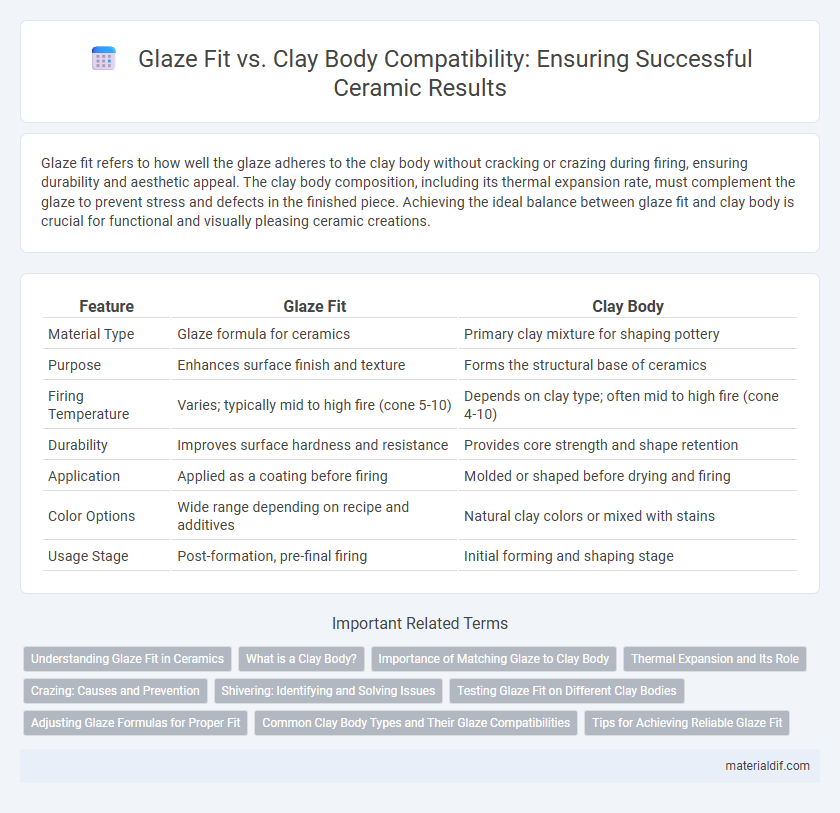

| Feature | Glaze Fit | Clay Body |

|---|---|---|

| Material Type | Glaze formula for ceramics | Primary clay mixture for shaping pottery |

| Purpose | Enhances surface finish and texture | Forms the structural base of ceramics |

| Firing Temperature | Varies; typically mid to high fire (cone 5-10) | Depends on clay type; often mid to high fire (cone 4-10) |

| Durability | Improves surface hardness and resistance | Provides core strength and shape retention |

| Application | Applied as a coating before firing | Molded or shaped before drying and firing |

| Color Options | Wide range depending on recipe and additives | Natural clay colors or mixed with stains |

| Usage Stage | Post-formation, pre-final firing | Initial forming and shaping stage |

Understanding Glaze Fit in Ceramics

Glaze fit in ceramics refers to the compatibility between the glaze and the clay body, ensuring that the glaze adheres properly without cracking or crazing. Proper glaze fit is achieved by matching the thermal expansion rates of both the glaze and clay body, which prevents stress during firing and cooling. Understanding the chemistry and physical properties of the clay body is essential for achieving a durable, defect-free ceramic surface.

What is a Clay Body?

A clay body is a blend of different clays and minerals formulated to achieve specific properties such as plasticity, firing temperature, and texture tailored for pottery or sculpture. It provides the fundamental structure and durability needed for ceramics, influencing the final product's strength and appearance. Understanding the clay body is essential for matching the appropriate glaze fit, as incompatible combinations can lead to issues like crazing or peeling.

Importance of Matching Glaze to Clay Body

Matching glaze to clay body is crucial for preventing defects such as crazing, peeling, and shivering in ceramics. Proper compatibility ensures thermal expansion rates align, maintaining structural integrity during firing and cooling cycles. Selecting a glaze formulated specifically for the clay body enhances durability, aesthetic quality, and longevity of the finished piece.

Thermal Expansion and Its Role

Thermal expansion plays a critical role in the interaction between glaze fit and clay body, impacting the durability and aesthetic quality of ceramic pieces. A glaze with a thermal expansion rate closely matched to the clay body minimizes stress during cooling, reducing the risk of crazing, flaking, or cracking. Understanding and controlling these thermal expansion properties ensures a strong and visually appealing bond between glaze and clay body.

Crazing: Causes and Prevention

Crazing occurs when the glaze contracts more than the clay body during cooling, causing surface cracks that compromise both aesthetics and durability. Preventing crazing involves matching the glaze's coefficient of thermal expansion closely with that of the specific clay body, ensuring proper firing schedules, and avoiding rapid cooling. Clay bodies with high thermal expansion rates, such as earthenware, require specially formulated glazes to minimize the mismatch and reduce risk of crazing.

Shivering: Identifying and Solving Issues

Shivering occurs when a glaze contracts more than the clay body during cooling, causing small flakes to peel off the ceramic surface. To solve shivering, potters can adjust the glaze recipe by reducing its silica content or increasing its coefficient of expansion to better match the clay body. Testing compatibility between the glaze fit and clay body through firing trials helps identify and prevent shivering in ceramics.

Testing Glaze Fit on Different Clay Bodies

Testing glaze fit on different clay bodies is essential to prevent defects like crazing or shivering, which result from mismatched thermal expansion rates. Conducting glaze fit tests involves applying the same glaze on various clay bodies, firing them under identical kiln schedules, and closely examining surface tension, cracking, and adhesion. Understanding variations in porosity, flux content, and firing temperature of each clay body helps potters achieve optimal glaze fit and durability.

Adjusting Glaze Formulas for Proper Fit

Adjusting glaze formulas for proper fit with a specific clay body involves balancing thermal expansion to prevent crazing or shivering. Testing glaze coefficients relative to the clay's maturation temperature ensures compatibility and durability. Precise modifications in silica and flux ratios help achieve optimal adherence and surface quality on the fired clay piece.

Common Clay Body Types and Their Glaze Compatibilities

Common clay body types include earthenware, stoneware, and porcelain, each with unique firing temperatures and compositions that affect glaze fit. Earthenware typically fires at lower temperatures (around 1,000degC to 1,150degC) and requires glazes formulated for porous surfaces to prevent crazing or peeling. Stoneware and porcelain fire at higher temperatures (1,200degC to 1,400degC), demanding glazes with compatible thermal expansion to ensure a strong, durable bond without cracking or shivering.

Tips for Achieving Reliable Glaze Fit

Achieving reliable glaze fit on clay bodies requires careful consideration of the thermal expansion rates to prevent crazing or peeling. Testing small glaze samples on the specific clay body and firing them through multiple cycles ensures compatibility and durability. Using a glaze formulated specifically for the clay's chemistry and consistently maintaining kiln temperatures within the recommended range can significantly improve glaze adhesion and finish.

Glaze Fit vs Clay Body Infographic

materialdif.com

materialdif.com