Terracotta is a porous, reddish clay primarily used for pottery and decorative objects, firing at lower temperatures, which results in a softer and more fragile finish. Fire clay, in contrast, is composed of highly refractory materials that withstand extremely high temperatures, making it ideal for industrial applications such as kiln linings and firebricks. The key difference lies in their heat resistance and structural durability, with fire clay offering greater strength and thermal stability compared to terracotta.

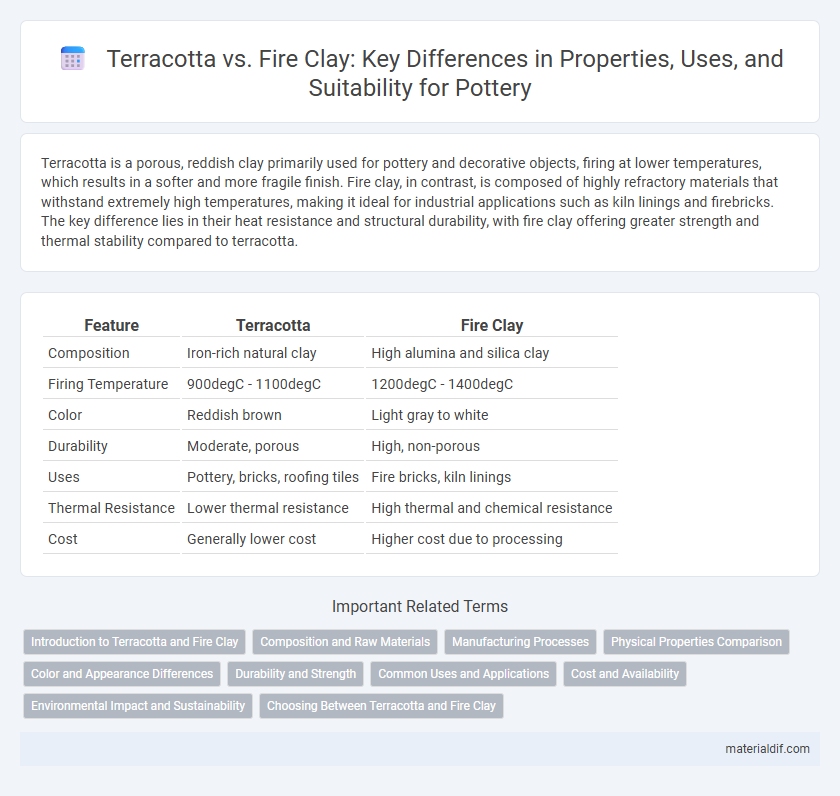

Table of Comparison

| Feature | Terracotta | Fire Clay |

|---|---|---|

| Composition | Iron-rich natural clay | High alumina and silica clay |

| Firing Temperature | 900degC - 1100degC | 1200degC - 1400degC |

| Color | Reddish brown | Light gray to white |

| Durability | Moderate, porous | High, non-porous |

| Uses | Pottery, bricks, roofing tiles | Fire bricks, kiln linings |

| Thermal Resistance | Lower thermal resistance | High thermal and chemical resistance |

| Cost | Generally lower cost | Higher cost due to processing |

Introduction to Terracotta and Fire Clay

Terracotta is a porous, reddish-brown clay fired at lower temperatures, commonly used for pottery, sculptures, and architectural elements due to its rustic aesthetic and breathability. Fire clay, on the other hand, possesses high refractory properties, allowing it to withstand extreme heat, making it ideal for kiln linings, firebricks, and industrial applications. Both types of clay serve distinct purposes, with terracotta emphasizing decorative and functional ceramics, while fire clay is primarily valued for thermal resistance.

Composition and Raw Materials

Terracotta is primarily composed of iron-rich clay, which gives it the characteristic reddish-brown color, and typically includes natural impurities like sand and silt that influence its porosity. Fire clay contains a higher percentage of alumina and silica, making it more refractory and resistant to high temperatures, and is often derived from deposits with low iron content to prevent discoloration. The raw materials for terracotta are sourced from softer, plastic clays, whereas fire clay is extracted from harder, more mature deposits that have undergone extensive weathering.

Manufacturing Processes

Terracotta is manufactured through a low-temperature firing process, typically between 1,000degC and 1,100degC, which results in a porous and reddish-orange product ideal for decorative and architectural uses. Fire clay undergoes high-temperature firing, often above 1,400degC, to achieve vitrification, creating a dense, heat-resistant material suitable for refractory applications such as kiln linings and crucibles. The distinction in firing temperatures and raw material composition directly influences the mechanical properties and intended industrial uses of terracotta and fire clay products.

Physical Properties Comparison

Terracotta exhibits lower density and porosity compared to fire clay, resulting in more absorbent and less durable pottery. Fire clay boasts higher refractoriness and thermal stability, making it ideal for high-temperature applications like kiln linings. The physical strength of fire clay surpasses terracotta, providing superior resistance to thermal shock and mechanical stress.

Color and Appearance Differences

Terracotta typically exhibits a warm reddish-brown color due to its high iron content, resulting in a porous, rustic appearance that is ideal for decorative pottery and garden planters. Fire clay, recognized for its pale gray or off-white hue, features a denser, smoother texture designed to withstand high temperatures in industrial applications such as kiln linings and refractory bricks. The visual distinctions between terracotta's earthy, rough look and fire clay's lighter, more refined surface highlight their different compositional properties and intended uses.

Durability and Strength

Terracotta, a porous ceramic made from low-fire clay, offers moderate durability suitable for decorative and light-use applications but lacks high strength under stress or impact. Fire clay, composed of refractory materials, withstands intense heat and mechanical stress due to its superior durability and high strength, making it ideal for industrial uses like kiln linings and firebricks. The dense structure and heat resistance of fire clay provide significantly greater longevity compared to the more brittle and absorbent terracotta.

Common Uses and Applications

Terracotta is primarily used for decorative pottery, roof tiles, and garden sculptures due to its porous nature and warm reddish color. Fire clay, known for its high refractory properties, is commonly utilized in kiln linings, firebrick production, and heat-resistant industrial components. Both materials serve distinct purposes, with terracotta favored for aesthetic applications and fire clay essential for high-temperature environments.

Cost and Availability

Terracotta is generally more affordable and widely available due to its abundance and simpler manufacturing process. Fire clay, known for its high heat resistance, tends to be more expensive and less readily available because it requires specific raw materials and processing. Budget-conscious projects often favor terracotta, while industrial applications prefer fire clay for durability despite higher costs.

Environmental Impact and Sustainability

Terracotta, made from natural red clay and fired at lower temperatures, generally consumes less energy and produces fewer carbon emissions compared to fire clay, which requires higher firing temperatures for its dense, refractory properties. Fire clay's durability and heat resistance often result in longer-lasting products, potentially reducing waste over time despite its higher initial environmental cost. Choosing terracotta supports more sustainable production methods, while fire clay contributes to sustainability through enhanced product lifespan and reduced frequency of replacement.

Choosing Between Terracotta and Fire Clay

Choosing between terracotta and fire clay depends on their thermal properties and intended use; terracotta is porous and ideal for decorative pottery and low-heat applications, while fire clay withstands high temperatures, making it better suited for kiln linings and industrial ceramics. Fire clay's high alumina content provides durability and heat resistance, whereas terracotta offers more aesthetic versatility due to its reddish color and ease of shaping. Understanding these material differences ensures the best selection for projects requiring specific heat tolerance and finishing qualities.

Terracotta vs Fire Clay Infographic

materialdif.com

materialdif.com