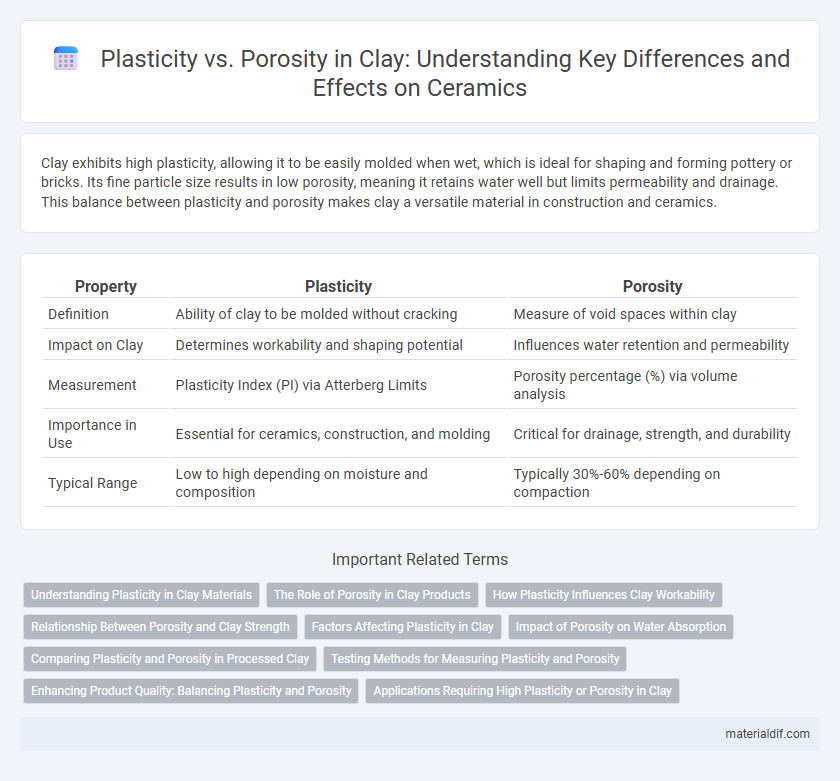

Clay exhibits high plasticity, allowing it to be easily molded when wet, which is ideal for shaping and forming pottery or bricks. Its fine particle size results in low porosity, meaning it retains water well but limits permeability and drainage. This balance between plasticity and porosity makes clay a versatile material in construction and ceramics.

Table of Comparison

| Property | Plasticity | Porosity |

|---|---|---|

| Definition | Ability of clay to be molded without cracking | Measure of void spaces within clay |

| Impact on Clay | Determines workability and shaping potential | Influences water retention and permeability |

| Measurement | Plasticity Index (PI) via Atterberg Limits | Porosity percentage (%) via volume analysis |

| Importance in Use | Essential for ceramics, construction, and molding | Critical for drainage, strength, and durability |

| Typical Range | Low to high depending on moisture and composition | Typically 30%-60% depending on compaction |

Understanding Plasticity in Clay Materials

Plasticity in clay materials refers to their ability to deform under stress without cracking, a property primarily influenced by the clay's mineralogy, water content, and particle size distribution. Unlike porosity, which measures the volume of void spaces within the clay, plasticity determines how clay can be shaped and molded, crucial for applications in ceramics, construction, and geotechnical engineering. High plasticity clays exhibit increased workability and cohesion, enabling better form retention and durability after drying and firing processes.

The Role of Porosity in Clay Products

Porosity in clay products significantly influences their strength, durability, and insulation properties by controlling the volume of air pockets within the material. Higher porosity leads to lower density and increased permeability, affecting water absorption and thermal resistance. Proper management of porosity during the firing process ensures optimal mechanical performance and longevity of clay ceramics and bricks.

How Plasticity Influences Clay Workability

Plasticity in clay directly affects its workability by determining how easily the material can be shaped without cracking or crumbling. High plasticity clay retains moisture effectively, allowing for smoother molding and better cohesion between particles during sculpting or construction. In contrast, clay with low plasticity tends to be more brittle and less adaptable, limiting its use in detailed or load-bearing applications.

Relationship Between Porosity and Clay Strength

Porosity in clay directly influences its strength, as higher porosity usually reduces the load-bearing capacity by increasing void spaces within the material. The inverse relationship between porosity and clay strength is critical in geotechnical engineering for predicting soil stability and settlement behavior. Understanding this relationship helps optimize clay use in construction by balancing plasticity and strength for improved durability and performance.

Factors Affecting Plasticity in Clay

Clay plasticity is primarily influenced by the mineral composition, particularly the presence of montmorillonite and kaolinite, which determine its ability to deform without cracking. Moisture content plays a critical role, as water acts as a lubricant between clay particles, enhancing plastic behavior. Temperature and organic matter content also affect plasticity by altering the clay's microstructure and particle interactions.

Impact of Porosity on Water Absorption

Porosity in clay significantly influences its water absorption capacity, as higher porosity allows more water to penetrate and be retained within the material. Increased porosity creates interconnected pore spaces that facilitate the movement and storage of water, directly affecting the clay's durability and structural integrity. Understanding the relationship between porosity and water absorption is essential for optimizing clay's performance in construction and ceramics.

Comparing Plasticity and Porosity in Processed Clay

Processed clay exhibits a balance between plasticity and porosity that determines its workability and durability. Higher plasticity allows for easier shaping and molding, while controlled porosity influences drying time and strength by regulating moisture retention. Optimizing the plasticity-to-porosity ratio is essential for producing clay products with minimal cracking and enhanced structural integrity.

Testing Methods for Measuring Plasticity and Porosity

Testing methods for measuring clay plasticity commonly involve the Atterberg Limits tests, including the Liquid Limit, Plastic Limit, and Shrinkage Limit, which quantify the clay's ability to deform without cracking. Porosity in clay is typically assessed through mercury intrusion porosimetry or water absorption tests, revealing the volume and distribution of pore spaces within the sample. Advanced techniques like X-ray computed tomography provide detailed visualization of pore structure and connectivity, enhancing the accuracy of porosity measurements.

Enhancing Product Quality: Balancing Plasticity and Porosity

Balancing plasticity and porosity in clay is crucial for enhancing product quality, as optimal plasticity ensures moldability while controlled porosity improves drying and firing performance. High plasticity clay allows for intricate shaping without cracking, whereas appropriate porosity prevents excessive shrinkage and enhances strength after firing. Achieving the ideal ratio between plasticity and porosity leads to durable, high-quality ceramic products with reduced defects.

Applications Requiring High Plasticity or Porosity in Clay

Clays with high plasticity are essential in ceramics and pottery, allowing for easy shaping and manipulation without cracking during drying or firing. High porosity clays are preferred in construction materials like lightweight blocks and filtration systems due to their ability to allow water and air flow while maintaining structural integrity. Industries such as wastewater treatment benefit from clays with both high plasticity and porosity, optimizing adsorptive properties and mechanical durability.

Plasticity vs Porosity Infographic

materialdif.com

materialdif.com