Vitrified clay undergoes a high-temperature firing process that transforms its structure into a glass-like, non-porous material, making it highly durable and resistant to water and chemicals. Non-vitrified clay, by contrast, remains porous and is more prone to absorbing moisture, which can affect its strength and longevity in certain applications. The choice between vitrified and non-vitrified clay depends on the intended use, with vitrified clay preferred for outdoor and high-moisture environments where durability is critical.

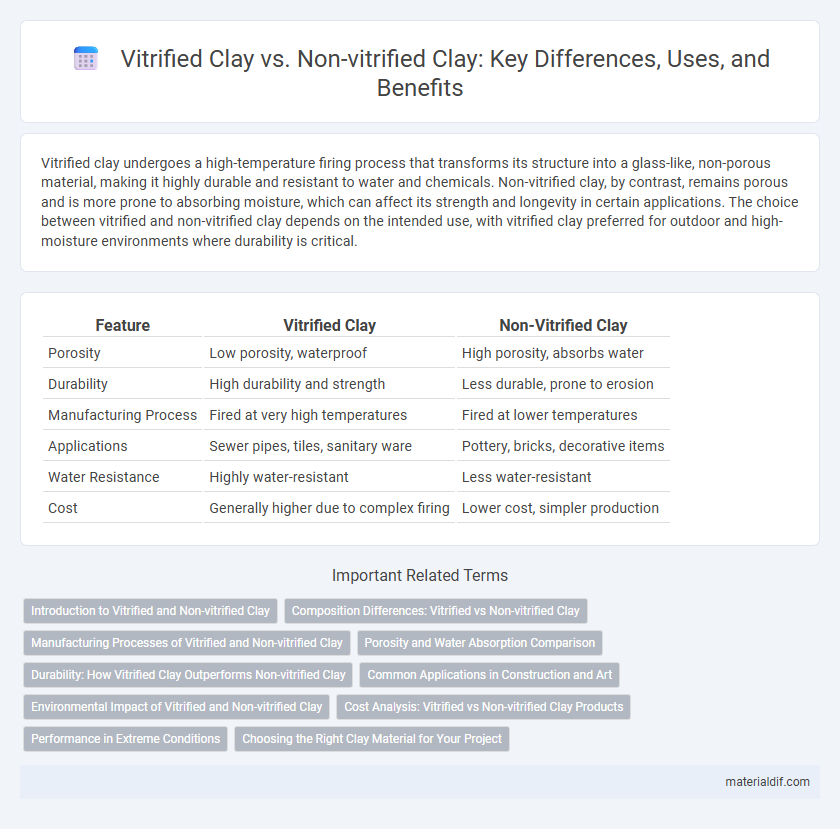

Table of Comparison

| Feature | Vitrified Clay | Non-Vitrified Clay |

|---|---|---|

| Porosity | Low porosity, waterproof | High porosity, absorbs water |

| Durability | High durability and strength | Less durable, prone to erosion |

| Manufacturing Process | Fired at very high temperatures | Fired at lower temperatures |

| Applications | Sewer pipes, tiles, sanitary ware | Pottery, bricks, decorative items |

| Water Resistance | Highly water-resistant | Less water-resistant |

| Cost | Generally higher due to complex firing | Lower cost, simpler production |

Introduction to Vitrified and Non-vitrified Clay

Vitrified clay undergoes a high-temperature firing process that transforms it into a dense, glass-like material with low porosity and enhanced strength, making it ideal for durable applications such as pipes and tiles. Non-vitrified clay remains porous and less compact as it is fired at lower temperatures or left unfired, retaining its natural absorptive qualities, commonly used in pottery and earthenware. Understanding the differences in firing methods and resulting physical properties is essential for selecting the appropriate type of clay for specific industrial or artistic purposes.

Composition Differences: Vitrified vs Non-vitrified Clay

Vitrified clay consists of a high percentage of silica and fluxing agents that, when fired at elevated temperatures, result in a glass-like, non-porous structure, enhancing strength and durability. Non-vitrified clay contains higher levels of alumina and iron oxides, which prevent full vitrification, leading to a more porous, less dense material ideal for water drainage applications. The key compositional difference lies in the silica content and firing temperature, determining the clay's degree of vitrification and its suitability for various industrial and construction uses.

Manufacturing Processes of Vitrified and Non-vitrified Clay

Vitrified clay undergoes a high-temperature firing process, typically above 1200degC, which causes the clay particles to fuse and become glass-like, resulting in a dense, impermeable structure. Non-vitrified clay is fired at lower temperatures, around 900-1100degC, leaving its porous structure largely intact and maintaining more absorbency. The manufacturing process of vitrified clay involves extended kiln firing and controlled cooling to achieve hardness and water resistance, whereas non-vitrified clay requires shorter firing times and less energy consumption, preserving its porous characteristics.

Porosity and Water Absorption Comparison

Vitrified clay exhibits significantly lower porosity compared to non-vitrified clay, resulting in enhanced durability and reduced water absorption rates, typically below 0.5%. Non-vitrified clay, characterized by higher porosity, can absorb water up to 10%, making it more susceptible to moisture damage and freeze-thaw cycles. This difference in porosity and water absorption impacts their applications, with vitrified clay preferred for plumbing and structural materials requiring water resistance.

Durability: How Vitrified Clay Outperforms Non-vitrified Clay

Vitrified clay exhibits superior durability compared to non-vitrified clay due to its enhanced density and reduced porosity achieved through high-temperature firing, resulting in greater resistance to water absorption and chemical corrosion. This durability makes vitrified clay ideal for applications such as sewer pipes and tiles where exposure to moisture and harsh environments is common. Non-vitrified clay, being more porous and less dense, tends to absorb more moisture, leading to increased susceptibility to cracking and degradation over time.

Common Applications in Construction and Art

Vitrified clay, known for its high density and low porosity, is commonly used in construction for sewer pipes, tiles, and bricks due to its durability and resistance to water absorption. Non-vitrified clay, which remains porous and less dense, is widely favored in artistic applications such as pottery, sculpture, and decorative ceramics for its workability and ability to absorb glazes. Both types of clay offer unique benefits tailored to their specific uses in structural longevity or creative expression.

Environmental Impact of Vitrified and Non-vitrified Clay

Vitrified clay offers enhanced durability and lower porosity, significantly reducing water infiltration and soil contamination compared to non-vitrified clay. The firing process of vitrified clay consumes more energy but results in longer-lasting products, minimizing waste and the need for frequent replacements. Non-vitrified clay, while requiring less energy to produce, tends to degrade faster, potentially increasing environmental impact through greater material consumption and disposal.

Cost Analysis: Vitrified vs Non-vitrified Clay Products

Vitrified clay products generally incur higher initial costs due to advanced firing processes that enhance durability and reduce porosity, leading to lower long-term maintenance expenses. Non-vitrified clay items are more affordable upfront but may require frequent repairs and replacements, increasing total lifetime costs. Evaluating cost-effectiveness requires balancing upfront investment with durability, especially in infrastructure projects where longevity is critical.

Performance in Extreme Conditions

Vitrified clay exhibits superior performance in extreme conditions due to its low porosity and high density, making it highly resistant to chemical corrosion and frost damage. Non-vitrified clay, with its porous structure, tends to absorb moisture and deteriorate faster when exposed to freeze-thaw cycles and harsh chemicals. The enhanced durability and structural integrity of vitrified clay make it ideal for applications requiring long-term resilience under severe environmental stresses.

Choosing the Right Clay Material for Your Project

Vitrified clay is characterized by its dense, non-porous structure achieved through high-temperature firing, making it ideal for projects requiring high durability and resistance to water absorption, such as sewer pipes and floor tiles. Non-vitrified clay retains more porosity and is less durable, suitable for decorative pottery and sculptures where aesthetic qualities outweigh structural strength. Selecting the right clay depends on the project's functional demands, balancing factors like water resistance, strength, and finish.

Vitrified Clay vs Non-vitrified Clay Infographic

materialdif.com

materialdif.com