Glaze fit refers to the smooth, even adhesion of glaze to the clay surface without cracks or peeling, ensuring a cohesive and durable finish. Glaze crawling occurs when the glaze shrinks more than the clay body or contamination prevents proper adhesion, causing bald spots or bare patches on the pottery. Understanding the clay and glaze chemistry helps prevent crawling and achieve a perfect glaze fit for both aesthetic appeal and functionality.

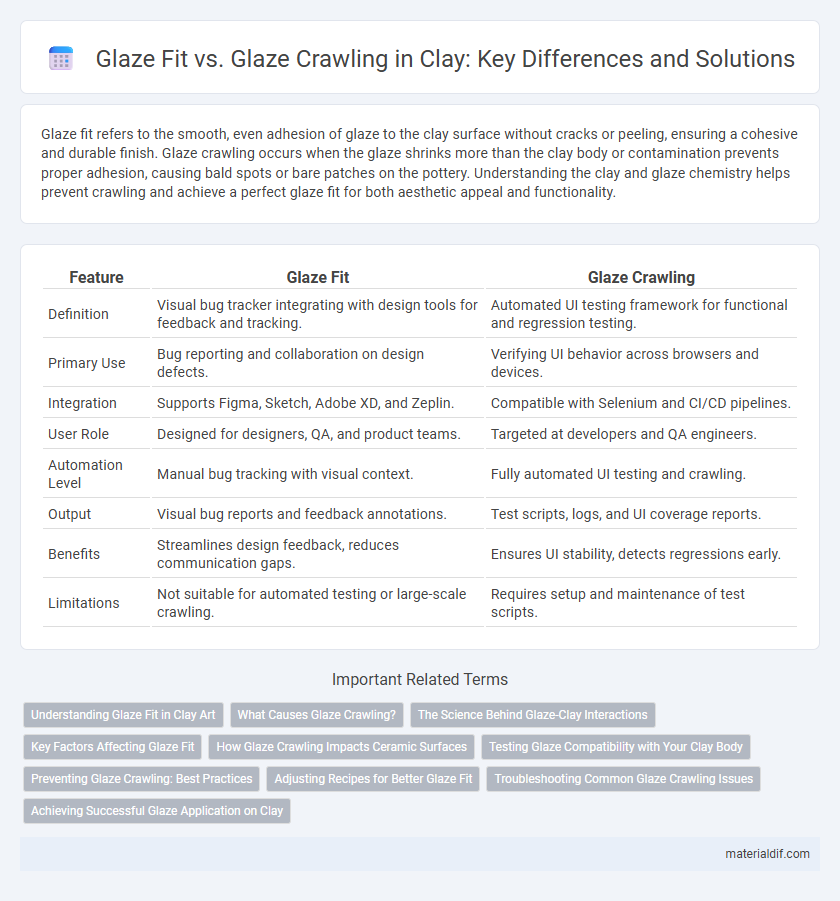

Table of Comparison

| Feature | Glaze Fit | Glaze Crawling |

|---|---|---|

| Definition | Visual bug tracker integrating with design tools for feedback and tracking. | Automated UI testing framework for functional and regression testing. |

| Primary Use | Bug reporting and collaboration on design defects. | Verifying UI behavior across browsers and devices. |

| Integration | Supports Figma, Sketch, Adobe XD, and Zeplin. | Compatible with Selenium and CI/CD pipelines. |

| User Role | Designed for designers, QA, and product teams. | Targeted at developers and QA engineers. |

| Automation Level | Manual bug tracking with visual context. | Fully automated UI testing and crawling. |

| Output | Visual bug reports and feedback annotations. | Test scripts, logs, and UI coverage reports. |

| Benefits | Streamlines design feedback, reduces communication gaps. | Ensures UI stability, detects regressions early. |

| Limitations | Not suitable for automated testing or large-scale crawling. | Requires setup and maintenance of test scripts. |

Understanding Glaze Fit in Clay Art

Glaze fit in clay art refers to the compatibility between the glaze and clay body during firing, ensuring that the glaze adheres smoothly without cracking or peeling. Poor glaze fit causes defects like glaze crawling, where the glaze pulls away from the clay surface, exposing bare areas. Mastering glaze fit involves matching the thermal expansion rates of glaze and clay to prevent stress, enhancing the durability and aesthetic finish of ceramic pieces.

What Causes Glaze Crawling?

Glaze crawling occurs when the glaze fails to adhere properly to the clay surface, often caused by dust, oil, or grease on the bisqueware, which prevents proper bonding. Excessive thickness of glaze application or incompatibility between glaze and clay body thermal expansion rates also contribute to crawling. Surface tension inconsistencies during firing lead to the glaze shrinking away, revealing bare clay beneath.

The Science Behind Glaze-Clay Interactions

Glaze fit and glaze crawling are critical phenomena influenced by the thermal expansion and surface tension between the clay body and glaze during firing. Glaze fit occurs when the glaze and clay have compatible coefficients of thermal expansion, ensuring the glaze remains smooth and adherent without cracking. In contrast, glaze crawling results from poor adhesion and surface tension imbalances, causing the glaze to retract and expose the bare clay beneath, often due to excessive surface contamination or mismatched thermal expansion rates.

Key Factors Affecting Glaze Fit

Glaze fit is primarily influenced by the thermal expansion compatibility between the clay body and glaze, with mismatches causing defects like crazing or crawling. Surface texture, glaze thickness, and firing temperature also significantly impact how well the glaze adheres and smooths over the clay surface. Properly balancing these factors ensures optimal glaze fit, reducing the risk of glaze crawling, which occurs when the glaze pulls away and leaves bare spots during firing.

How Glaze Crawling Impacts Ceramic Surfaces

Glaze crawling creates an uneven, patchy surface on ceramics due to poor adhesion between the glaze and clay body, often caused by surface contamination or improper drying. This defect results in exposed areas of clay where the glaze has retracted, leading to a rough texture and compromised durability. Understanding the factors that trigger glaze crawling helps potters adjust clay and glaze formulations to achieve a smooth, consistent finish.

Testing Glaze Compatibility with Your Clay Body

Testing glaze compatibility with your clay body is essential to avoid issues like glaze fit problems or glaze crawling defects. Glaze fit occurs when the glaze and clay body expand and contract at different rates during firing, causing crazing or cracking, while glaze crawling results from poor adhesion due to surface contamination or excessive glaze thickness. Conducting test tiles and varying firing schedules helps identify the ideal glaze composition and application thickness to ensure optimal glaze fit and prevent crawling on your specific clay body.

Preventing Glaze Crawling: Best Practices

Preventing glaze crawling involves thorough surface preparation and ensuring the clay is free of dust, grease, or oils before applying the glaze. Applying the glaze in thin, even layers and avoiding overly thick coats helps maintain consistent adhesion to the clay body. Proper drying and firing protocols, including gradual temperature increases, reduce the risk of glaze defects like crawling and promote optimal glaze fit.

Adjusting Recipes for Better Glaze Fit

Adjusting glaze recipes for better glaze fit involves carefully balancing the thermal expansion to prevent defects like glaze crawling or fit issues. Increasing the silica content or modifying fluxes such as potassium or sodium can enhance glaze adhesion and reduce tension. Precise testing with melt fluidity and firing temperature adjustments ensures the glaze conforms properly to the clay body without crawling or cracking.

Troubleshooting Common Glaze Crawling Issues

Glaze crawling occurs when the glaze pulls away from the clay surface, often caused by improper application, dirty or dusty bisque ware, or a surface that repels the glaze, such as a wax resist or greasy spot. To troubleshoot glaze crawling, ensure the clay body is thoroughly cleaned, bisque fire temperature is appropriate, and the glaze layer is applied evenly without excessive thickness. Adjusting glaze chemistry to increase adhesion and avoiding contamination during firing can also help prevent recurring crawling defects.

Achieving Successful Glaze Application on Clay

Glaze fit refers to the compatibility between the glaze and clay body, ensuring the glaze adheres smoothly without tension, while glaze crawling occurs when poor fit causes the glaze to pull away in patches during firing. Achieving successful glaze application requires matching the thermal expansion rates of both the glaze and clay to prevent cracks and crawling defects. Proper surface preparation and controlled application thickness also promote even coverage and avoid issues related to glaze fit.

Glaze Fit vs Glaze Crawling Infographic

materialdif.com

materialdif.com