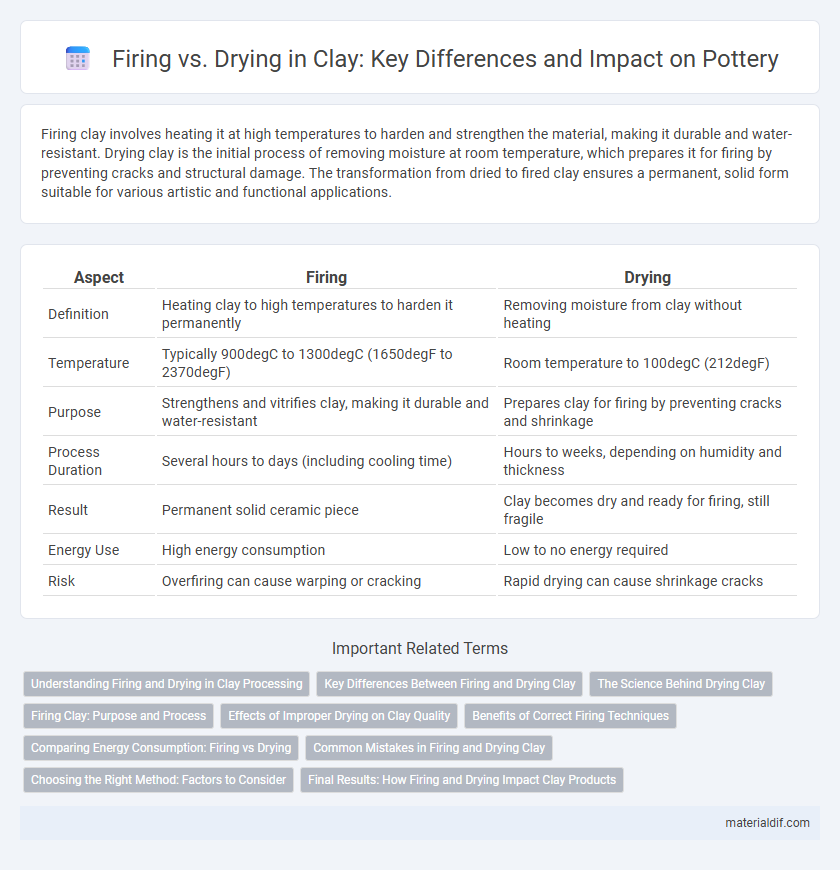

Firing clay involves heating it at high temperatures to harden and strengthen the material, making it durable and water-resistant. Drying clay is the initial process of removing moisture at room temperature, which prepares it for firing by preventing cracks and structural damage. The transformation from dried to fired clay ensures a permanent, solid form suitable for various artistic and functional applications.

Table of Comparison

| Aspect | Firing | Drying |

|---|---|---|

| Definition | Heating clay to high temperatures to harden it permanently | Removing moisture from clay without heating |

| Temperature | Typically 900degC to 1300degC (1650degF to 2370degF) | Room temperature to 100degC (212degF) |

| Purpose | Strengthens and vitrifies clay, making it durable and water-resistant | Prepares clay for firing by preventing cracks and shrinkage |

| Process Duration | Several hours to days (including cooling time) | Hours to weeks, depending on humidity and thickness |

| Result | Permanent solid ceramic piece | Clay becomes dry and ready for firing, still fragile |

| Energy Use | High energy consumption | Low to no energy required |

| Risk | Overfiring can cause warping or cracking | Rapid drying can cause shrinkage cracks |

Understanding Firing and Drying in Clay Processing

Firing in clay processing involves heating the clay to high temperatures, typically between 1,000degC and 1,300degC, to harden and vitrify the material, transforming it into durable ceramic. Drying is the initial stage where moisture evaporates from the shaped clay at ambient temperatures or controlled conditions, reducing the risk of cracking during firing. Understanding the balance between drying and firing is crucial for achieving structural integrity and optimal physical properties in ceramic products.

Key Differences Between Firing and Drying Clay

Firing clay involves heating the material in a kiln to high temperatures, causing chemical and physical transformations that harden and strengthen the clay. Drying clay is the process of removing moisture naturally from the surface at room temperature, which prepares the piece for firing but does not increase its durability or permanence. Key differences include drying being essential but insufficient alone for permanence, whereas firing creates a vitrified, durable ceramic that resists water and wear.

The Science Behind Drying Clay

Drying clay involves the evaporation of water from its porous structure, causing the particles to draw closer and form a solid but fragile state. Firing, in contrast, subjects the dried clay to high temperatures that chemically alter the minerals, creating a durable, vitrified material. Understanding the moisture content and evaporation rate is crucial for preventing cracks and ensuring even drying before firing.

Firing Clay: Purpose and Process

Firing clay transforms raw ceramics into durable, hardened objects through controlled exposure to high temperatures typically between 1,800degF and 2,400degF (980degC to 1,315degC). This thermal process causes chemical and physical changes such as vitrification and sintering, which strengthen the clay body and make it water-resistant. Unlike drying, which removes moisture to prevent cracking, firing permanently alters clay's structure, ensuring longevity and functional integrity.

Effects of Improper Drying on Clay Quality

Improper drying of clay leads to cracks, warping, and weakened structural integrity, significantly reducing the quality of the final fired product. Moisture trapped within unevenly dried clay causes steam explosions during firing, resulting in breakage or deformation. Consistent and controlled drying is essential to ensure that the clay body retains its intended shape, strength, and durability after firing.

Benefits of Correct Firing Techniques

Correct firing techniques enhance the durability and strength of clay products by promoting optimal vitrification, which reduces porosity and increases resistance to water and mechanical stress. Proper firing also prevents structural flaws, such as cracks and warping, ensuring the longevity and aesthetic quality of ceramic pieces. Controlled temperature profiles minimize thermal shock, preserving the integrity of the clay body and glaze for high-quality finished ceramics.

Comparing Energy Consumption: Firing vs Drying

Firing clay consumes significantly more energy than drying, as the kiln temperatures often exceed 1,000degC compared to the ambient heat used in drying processes. Drying primarily relies on natural or low-energy heat sources to remove moisture, whereas firing requires sustained high temperatures to vitrify the clay. Energy efficiency considerations favor drying, but firing is essential to achieve the final material strength and durability in ceramic products.

Common Mistakes in Firing and Drying Clay

Common mistakes in firing and drying clay include rushing the drying process, which causes cracking and warping due to uneven moisture evaporation. Firing clay too quickly or at incorrect temperatures leads to thermal shock, resulting in breakage or incomplete vitrification. Ensuring gradual drying and controlled kiln heating prevents structural damage and preserves the integrity of the ceramic piece.

Choosing the Right Method: Factors to Consider

Choosing the right method between firing and drying clay depends on factors like the intended durability, moisture content, and final use of the piece. Firing involves heating clay at high temperatures to achieve permanent hardness and strength, ideal for functional pottery and ceramics. Drying, a slower moisture evaporation process, is suited for delicate or decorative items that may not withstand kiln firing.

Final Results: How Firing and Drying Impact Clay Products

Firing transforms clay by permanently hardening its structure through high-temperature heat, resulting in increased durability, water resistance, and a finished texture that cannot be altered without damage. Drying simply removes moisture from the clay, making it rigid but still fragile and prone to breakage without firing. The final quality, strength, and usability of clay products depend on successful firing rather than drying alone.

Firing vs Drying Infographic

materialdif.com

materialdif.com