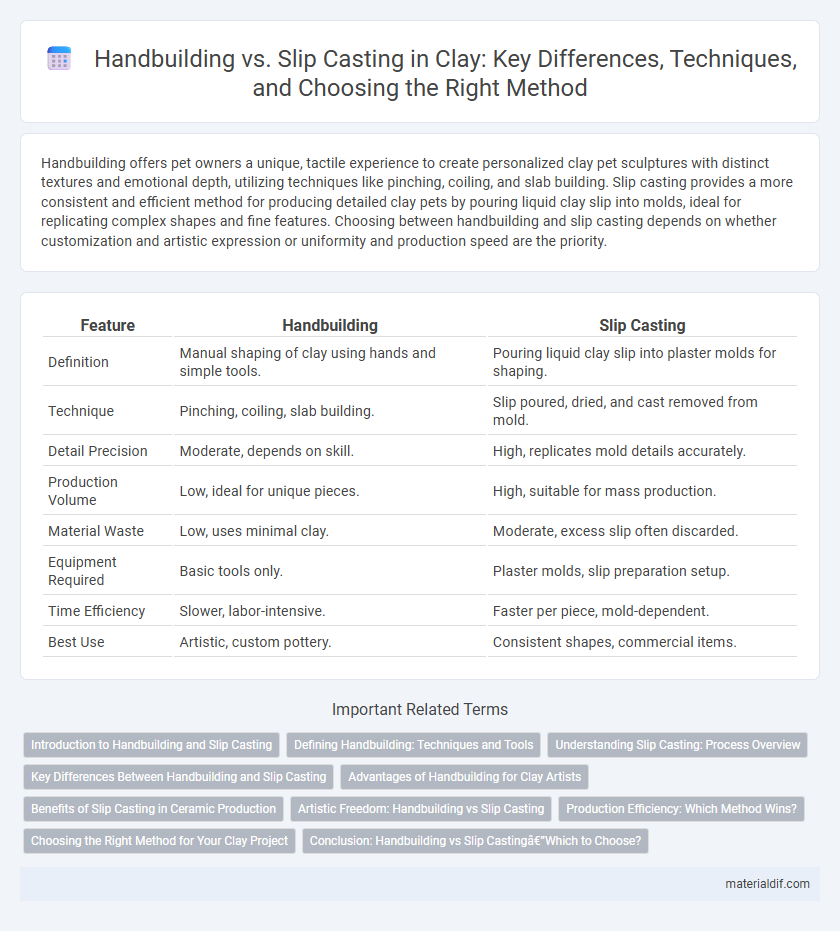

Handbuilding offers pet owners a unique, tactile experience to create personalized clay pet sculptures with distinct textures and emotional depth, utilizing techniques like pinching, coiling, and slab building. Slip casting provides a more consistent and efficient method for producing detailed clay pets by pouring liquid clay slip into molds, ideal for replicating complex shapes and fine features. Choosing between handbuilding and slip casting depends on whether customization and artistic expression or uniformity and production speed are the priority.

Table of Comparison

| Feature | Handbuilding | Slip Casting |

|---|---|---|

| Definition | Manual shaping of clay using hands and simple tools. | Pouring liquid clay slip into plaster molds for shaping. |

| Technique | Pinching, coiling, slab building. | Slip poured, dried, and cast removed from mold. |

| Detail Precision | Moderate, depends on skill. | High, replicates mold details accurately. |

| Production Volume | Low, ideal for unique pieces. | High, suitable for mass production. |

| Material Waste | Low, uses minimal clay. | Moderate, excess slip often discarded. |

| Equipment Required | Basic tools only. | Plaster molds, slip preparation setup. |

| Time Efficiency | Slower, labor-intensive. | Faster per piece, mold-dependent. |

| Best Use | Artistic, custom pottery. | Consistent shapes, commercial items. |

Introduction to Handbuilding and Slip Casting

Handbuilding is a traditional clay modeling technique involving shaping clay manually using hands and simple tools to create unique, textured pottery pieces. Slip casting employs liquid clay slip poured into plaster molds, allowing for precise replication and smooth, uniform ceramic forms. Both methods offer distinct advantages for artists, with handbuilding emphasizing creative expression and slip casting focusing on efficiency and consistency.

Defining Handbuilding: Techniques and Tools

Handbuilding in clay involves shaping forms manually using techniques such as pinching, coiling, and slab construction, allowing for unique, tactile artistry. Essential tools include wooden modeling tools, wire cutters, rib tools, and sponges, which aid in refining shapes and textures. This method offers greater creative control compared to slip casting by emphasizing the artist's direct interaction with the clay.

Understanding Slip Casting: Process Overview

Slip casting involves pouring liquid clay, known as slip, into plaster molds that absorb water and solidify the clay against the mold walls. This technique allows for precise replication of intricate shapes and is ideal for producing multiple uniform pieces with fine detail. Key factors influencing slip casting quality include slip viscosity, mold porosity, and drying time.

Key Differences Between Handbuilding and Slip Casting

Handbuilding in clay involves directly shaping the material using hands and simple tools, allowing for organic, unique forms with texture variations, while slip casting uses liquid clay poured into molds for consistent, reproducible shapes. Handbuilding techniques such as pinching, coiling, and slab construction offer creative flexibility, whereas slip casting emphasizes efficiency and uniformity in mass production. The drying and firing processes also differ, with handbuilt pieces requiring careful attention to thickness variation to avoid cracking and slip cast items benefiting from uniform wall thickness for structural stability.

Advantages of Handbuilding for Clay Artists

Handbuilding offers clay artists unparalleled creative control, enabling unique textures and forms that slip casting cannot replicate. This technique fosters a direct, tactile connection with the clay, enhancing artistic expression and allowing spontaneous adjustments during the crafting process. Unlike slip casting, handbuilding requires minimal equipment, making it accessible and suitable for both beginners and experienced artisans seeking personalized, one-of-a-kind ceramic pieces.

Benefits of Slip Casting in Ceramic Production

Slip casting offers precise control over complex shapes and fine details, enabling consistent replication of intricate ceramic designs. The process reduces material waste by using liquid clay slip, which fills molds efficiently and promotes uniform drying and firing. This method is highly scalable, making it ideal for mass production while maintaining high-quality surface finishes and minimizing labor costs.

Artistic Freedom: Handbuilding vs Slip Casting

Handbuilding in clay offers unparalleled artistic freedom, allowing artists to shape, texture, and customize their pieces with direct tactile control, resulting in unique, expressive forms. Slip casting, while efficient for producing uniform and intricate shapes, limits spontaneity and personal touch due to its reliance on molds. The choice between handbuilding and slip casting significantly influences the creative process and artistic outcomes in ceramic art.

Production Efficiency: Which Method Wins?

Handbuilding offers greater artistic flexibility but demands more time and skilled labor, limiting production efficiency. Slip casting excels in mass production by rapidly creating consistent, intricate shapes with minimal manual intervention. Factories favor slip casting when prioritizing high-volume output and reduced labor costs over custom craftsmanship.

Choosing the Right Method for Your Clay Project

Handbuilding offers tactile control and artistic flexibility, ideal for one-of-a-kind sculptures or intricate details, while slip casting suits mass production with consistent shapes and smooth finishes. Selecting the right method depends on the project scale, desired surface texture, and production speed; handbuilding excels in customization, whereas slip casting provides efficiency and uniformity. Understanding the clay body's compatibility with either technique ensures optimal drying, firing, and final durability for your ceramic piece.

Conclusion: Handbuilding vs Slip Casting—Which to Choose?

Handbuilding offers tactile control and artistic freedom, ideal for unique, handcrafted pottery with intricate textures. Slip casting enables high-volume production with uniform shapes, leveraging molds to replicate detailed designs efficiently. Selecting between handbuilding and slip casting depends on whether the priority is artistic expression or consistent, large-scale manufacturing.

Handbuilding vs Slip Casting Infographic

materialdif.com

materialdif.com