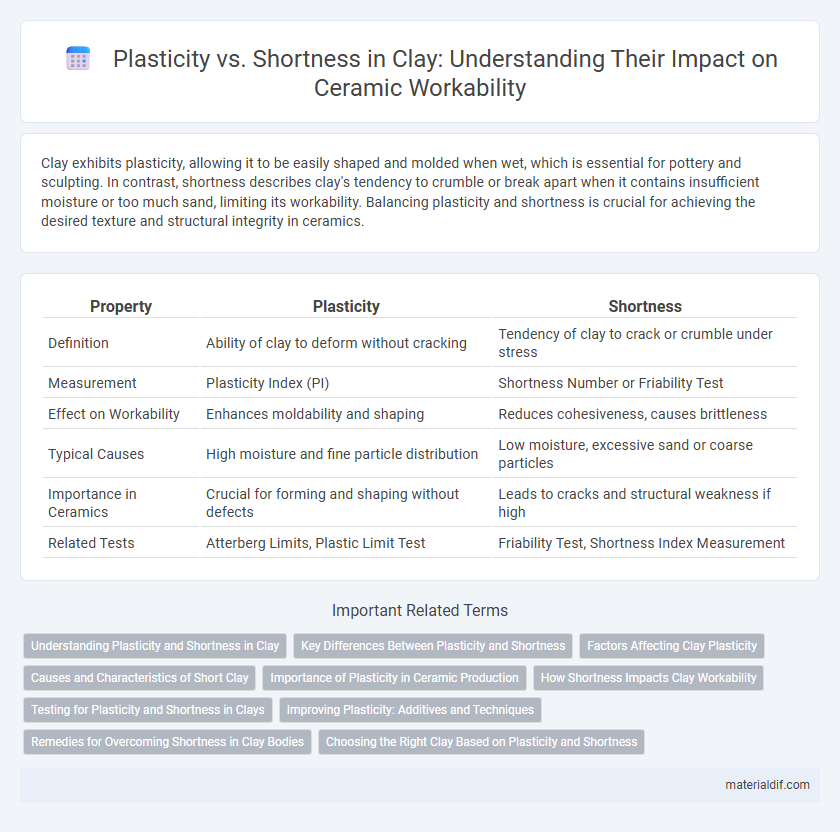

Clay exhibits plasticity, allowing it to be easily shaped and molded when wet, which is essential for pottery and sculpting. In contrast, shortness describes clay's tendency to crumble or break apart when it contains insufficient moisture or too much sand, limiting its workability. Balancing plasticity and shortness is crucial for achieving the desired texture and structural integrity in ceramics.

Table of Comparison

| Property | Plasticity | Shortness |

|---|---|---|

| Definition | Ability of clay to deform without cracking | Tendency of clay to crack or crumble under stress |

| Measurement | Plasticity Index (PI) | Shortness Number or Friability Test |

| Effect on Workability | Enhances moldability and shaping | Reduces cohesiveness, causes brittleness |

| Typical Causes | High moisture and fine particle distribution | Low moisture, excessive sand or coarse particles |

| Importance in Ceramics | Crucial for forming and shaping without defects | Leads to cracks and structural weakness if high |

| Related Tests | Atterberg Limits, Plastic Limit Test | Friability Test, Shortness Index Measurement |

Understanding Plasticity and Shortness in Clay

Plasticity in clay refers to its ability to be shaped and molded without cracking, which depends on the clay's moisture content and particle size distribution. Shortness in clay, characterized by a lack of plasticity, results in brittleness and difficulty in molding due to coarser particles or insufficient water. Understanding the balance between plasticity and shortness is crucial for ceramic artists and engineers to achieve desired workability and structural integrity in clay products.

Key Differences Between Plasticity and Shortness

Plasticity in clay refers to its ability to be molded and retain shape without cracking, primarily influenced by water content and particle size, whereas shortness describes clay's tendency to crumble or lack cohesiveness due to insufficient moisture or alteration in mineral composition. High plasticity clays exhibit fine particles and strong bonds, enabling smooth shaping processes, while short clays contain coarser particles or impurities, resulting in brittle behavior and reduced workability. Understanding these differences is crucial for applications in pottery, construction, and ceramics to ensure optimal material performance.

Factors Affecting Clay Plasticity

Clay plasticity depends on factors such as mineral composition, water content, and grain size distribution, which influence its malleability and workability. Higher amounts of montmorillonite increase plasticity, while kaolinite results in lower plasticity due to its coarser grains. Temperature and organic matter presence also play crucial roles in modifying the clay's ability to retain shape without cracking or crumbling.

Causes and Characteristics of Short Clay

Short clay is characterized by low plasticity, causing it to be stiff and crumbly rather than pliable and moldable. This reduced plasticity results from a low water content and a predominance of larger particle sizes, such as silt and sand, which limit clay particle cohesion. The causes of shortness also include mineral composition, with fewer swelling minerals like montmorillonite, leading to poor plastic behavior and increased brittleness.

Importance of Plasticity in Ceramic Production

Plasticity is a crucial property of clay that determines its workability and ability to be shaped without cracking, directly affecting the quality of ceramic production. High plasticity clay contains fine particles and sufficient moisture, allowing artisans to mold intricate designs and maintain structural integrity during drying and firing. Insufficient plasticity leads to brittleness and shrinkage, resulting in defects like warping or fractures in the final ceramic product.

How Shortness Impacts Clay Workability

Shortness in clay refers to its tendency to break or crumble under stress, directly impacting workability by limiting plastic deformation. High shortness results in reduced cohesiveness, making the clay less tolerant of shaping and more prone to cracks during drying or firing. Optimal workability is achieved when shortness is minimized, allowing the clay to maintain flexibility while retaining its structural integrity.

Testing for Plasticity and Shortness in Clays

Testing for plasticity in clays involves measuring the soil's ability to deform without cracking using Atterberg limits, specifically the plastic limit and plasticity index values. Shortness is assessed by evaluating the clay's resistance to elongation and its tendency to break or crumble under stress, often analyzed through penetrometer or extensometer tests. Accurate determination of these properties is essential for predicting clay behavior in construction and ceramic applications.

Improving Plasticity: Additives and Techniques

Improving plasticity in clay involves integrating specific additives such as bentonite or ball clay, which enhance its workability and moisture retention. Techniques like wedging and soaking also contribute significantly to increasing plasticity by aligning clay particles and maintaining optimal hydration. These methods collectively prevent shortness, ensuring the clay remains pliable and less prone to cracking during shaping and drying.

Remedies for Overcoming Shortness in Clay Bodies

Shortness in clay bodies, characterized by poor plasticity and limited workability, can be effectively remedied by increasing the proportion of fine-grained plastic clay minerals like kaolinite or ball clay. Introducing organic additives such as bentonite, or incorporating grog and sand in controlled amounts, enhances particle cohesion and reduces brittleness. Proper wedging and moisture control during preparation further improve the plasticity and prevent cracking, enabling smoother forming and shaping processes.

Choosing the Right Clay Based on Plasticity and Shortness

Selecting the right clay involves balancing plasticity and shortness to suit your project's needs. High plasticity clays offer excellent flexibility and workability for intricate shapes but may require longer drying times, while clays with greater shortness are firmer, reduce shrinkage, and resist deformation during firing. Evaluating these properties helps potters achieve desired strength, texture, and durability in ceramics.

Plasticity vs Shortness Infographic

materialdif.com

materialdif.com