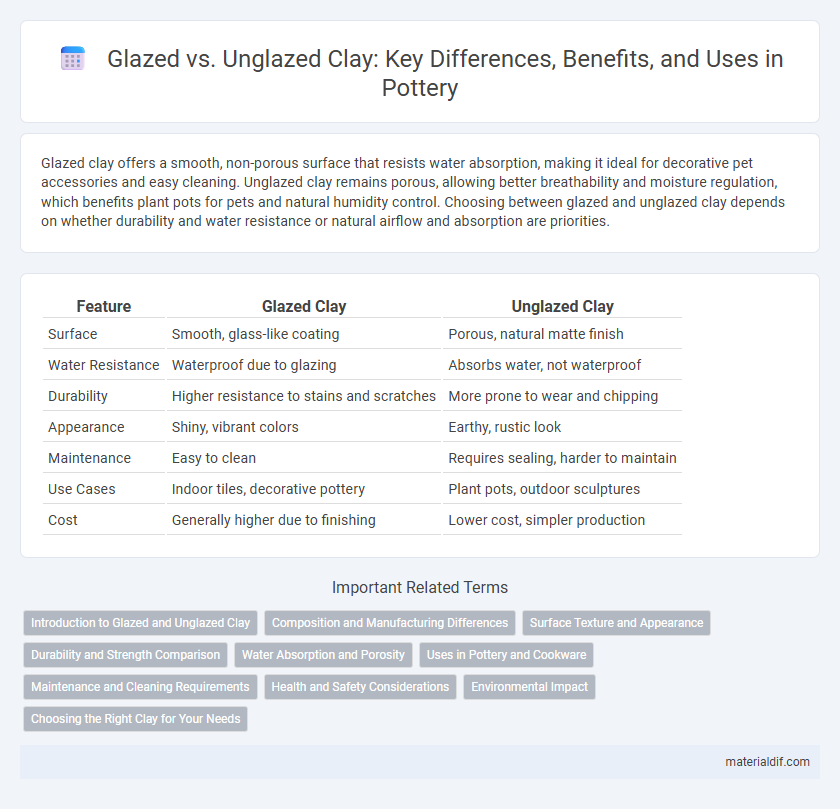

Glazed clay offers a smooth, non-porous surface that resists water absorption, making it ideal for decorative pet accessories and easy cleaning. Unglazed clay remains porous, allowing better breathability and moisture regulation, which benefits plant pots for pets and natural humidity control. Choosing between glazed and unglazed clay depends on whether durability and water resistance or natural airflow and absorption are priorities.

Table of Comparison

| Feature | Glazed Clay | Unglazed Clay |

|---|---|---|

| Surface | Smooth, glass-like coating | Porous, natural matte finish |

| Water Resistance | Waterproof due to glazing | Absorbs water, not waterproof |

| Durability | Higher resistance to stains and scratches | More prone to wear and chipping |

| Appearance | Shiny, vibrant colors | Earthy, rustic look |

| Maintenance | Easy to clean | Requires sealing, harder to maintain |

| Use Cases | Indoor tiles, decorative pottery | Plant pots, outdoor sculptures |

| Cost | Generally higher due to finishing | Lower cost, simpler production |

Introduction to Glazed and Unglazed Clay

Glazed clay features a smooth, glass-like coating fused to its surface through high-temperature firing, enhancing water resistance and aesthetic appeal. Unglazed clay retains its porous texture, allowing for breathability and natural moisture absorption, commonly used in pottery and horticulture. The choice between glazed and unglazed clay depends on functional requirements such as durability, permeability, and decorative finish.

Composition and Manufacturing Differences

Glazed clay is coated with a vitreous layer made from silica, fluxes, and metal oxides, which is fused onto the clay body at high temperatures to create a non-porous surface, while unglazed clay remains porous and retains its natural texture. The manufacturing process of glazed clay involves an additional firing step, usually in a kiln at temperatures between 1,000degC and 1,300degC, enabling the glaze to melt and bond with the clay, unlike unglazed clay that is typically fired once. Compositionally, glazed clay often includes added fluxes and colorants in the glaze mixture, whereas unglazed clay comprises primarily natural clay minerals such as kaolinite, illite, and montmorillonite without surface treatments.

Surface Texture and Appearance

Glazed clay features a smooth, glossy surface with a shiny finish that enhances color vibrancy and provides a waterproof layer, making it ideal for decorative and functional pottery. Unglazed clay retains a porous, matte texture with a natural, earthy appearance, offering a tactile, rustic feel often preferred for garden pots and earthenware. Surface texture distinctly affects visual appeal and usability, with glazing creating a sleek, reflective look while unglazed finishes emphasize roughness and natural imperfections.

Durability and Strength Comparison

Glazed clay exhibits enhanced durability due to its protective, non-porous surface that resists moisture, stains, and wear, making it ideal for high-traffic areas and outdoor use. Unglazed clay, while more porous and susceptible to chipping, offers increased strength and better slip resistance because it maintains its natural texture and composition. The choice between glazed and unglazed clay depends on balancing the need for surface protection against the inherent toughness and grip provided by unglazed materials.

Water Absorption and Porosity

Glazed clay features a vitrified surface that significantly reduces water absorption, often below 1%, making it highly resistant to moisture penetration compared to unglazed clay, which typically exhibits water absorption rates between 5% and 15%. The glazing process creates a non-porous layer, drastically minimizing porosity and enhancing durability against water damage. In contrast, unglazed clay retains its natural porous structure, leading to higher permeability and greater susceptibility to moisture-related wear.

Uses in Pottery and Cookware

Glazed clay offers a non-porous, smooth surface ideal for pottery that requires water retention and easy cleaning, making it perfect for cookware like baking dishes and casseroles. Unglazed clay, known for its porous nature, excels in pottery designed for slow cooking and moisture absorption, such as traditional clay pots that enhance flavor by allowing steam circulation. Both types are integral in ceramics, but glazed clay suits decorative and functional uses requiring a seal, while unglazed clay is prized for its natural heat distribution and breathability.

Maintenance and Cleaning Requirements

Glazed clay surfaces require less maintenance due to their protective coating, which resists stains, moisture, and dirt buildup, making cleaning easier with just mild soap and water. Unglazed clay, being porous, demands more frequent sealing to prevent absorption of liquids and stains, and cleaning typically involves specialized, pH-neutral cleaners to avoid damage. Consistent upkeep of glazed clay extends its lifespan and appearance, while unglazed clay requires more diligent care to maintain structural integrity and aesthetic quality.

Health and Safety Considerations

Glazed clay offers a non-porous surface that resists bacteria and mold growth, making it safer for food storage and cooking compared to unglazed clay, which can absorb moisture and harbor harmful pathogens. The glazing process seals the clay, reducing the risk of chemical leaching, while some unglazed clay contains naturally occurring elements like lead or cadmium that pose health hazards if improperly fired. Proper use and sourcing of both glazed and unglazed clay ensure their safety, but glazed clay generally provides more reliable protection against contamination in health-sensitive applications.

Environmental Impact

Glazed clay involves a coating that often contains chemical substances requiring high-temperature kilns, increasing energy consumption and environmental emissions. Unglazed clay, being natural and untreated, has a lower environmental footprint due to minimal processing and absence of synthetic coatings. Choosing unglazed clay reduces pollution and promotes sustainability by maintaining the material's biodegradability and recyclability.

Choosing the Right Clay for Your Needs

Glazed clay offers a smooth, non-porous surface that enhances durability and makes it ideal for functional items like cookware and decorative pieces requiring water resistance. Unglazed clay retains its natural texture and breathability, making it preferred for pottery that benefits from air exchange or rustic aesthetics. Selecting between glazed and unglazed clay depends on the intended use, with glazed clay suited for moisture-prone environments and unglazed clay favored for ventilation and organic finishes.

Glazed Clay vs Unglazed Clay Infographic

materialdif.com

materialdif.com