Grogged clay contains pre-fired clay particles that enhance its strength, reduce shrinkage, and improve texture, making it ideal for sculpting and hand-building. Smooth clay, free of grog, offers a finer surface finish suitable for detailed work and wheel throwing, but it tends to shrink more and can be more prone to warping. Choosing between grogged and smooth clay depends on the project requirements, balancing durability with surface texture.

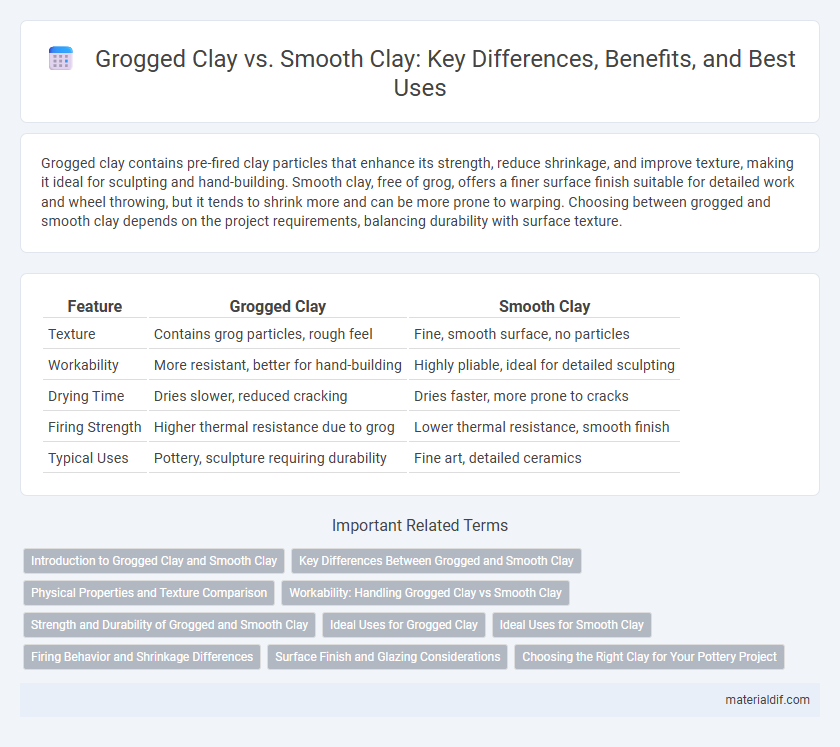

Table of Comparison

| Feature | Grogged Clay | Smooth Clay |

|---|---|---|

| Texture | Contains grog particles, rough feel | Fine, smooth surface, no particles |

| Workability | More resistant, better for hand-building | Highly pliable, ideal for detailed sculpting |

| Drying Time | Dries slower, reduced cracking | Dries faster, more prone to cracks |

| Firing Strength | Higher thermal resistance due to grog | Lower thermal resistance, smooth finish |

| Typical Uses | Pottery, sculpture requiring durability | Fine art, detailed ceramics |

Introduction to Grogged Clay and Smooth Clay

Grogged clay contains pre-fired clay particles called grog, which improve texture, reduce shrinkage, and enhance strength during firing. Smooth clay, free of grog, offers a fine, pliable surface ideal for detailed sculpting and intricate work. The choice between grogged and smooth clay depends on the desired durability and finish of the final ceramic piece.

Key Differences Between Grogged and Smooth Clay

Grogged clay contains pre-fired clay particles, known as grog, which enhance its structural strength, reduce shrinkage, and improve thermal resistance during firing. Smooth clay lacks these inclusions, resulting in a finer texture but increased susceptibility to cracking and warping. The choice between grogged and smooth clay depends on the desired durability and surface finish in ceramic projects.

Physical Properties and Texture Comparison

Grogged clay contains pre-fired clay particles that enhance its physical properties by reducing shrinkage and increasing thermal shock resistance, making it ideal for hand-building and wheel-throwing projects requiring durability. Smooth clay, lacking these grog inclusions, offers a finer texture with greater plasticity and workability, preferred for detailed sculpting and delicate finishes. The coarse texture of grogged clay provides a gritty, tactile feel that improves structural strength, whereas smooth clay's silky surface allows for seamless shaping and smooth surface treatments.

Workability: Handling Grogged Clay vs Smooth Clay

Grogged clay contains pre-fired particles that improve its workability by reducing shrinkage and enhancing texture, making it ideal for hand-building and wheel-throwing when structural strength is needed. Smooth clay offers a finer, more consistent texture that is easier to shape and detail but can be more prone to cracking during drying and firing. Artists often choose grogged clay for larger or more complex forms due to its durability, while smooth clay suits detailed sculpting and surface finishing.

Strength and Durability of Grogged and Smooth Clay

Grogged clay contains coarse particles of pre-fired clay that enhance its strength and durability by reducing shrinkage and minimizing cracking during drying and firing. Smooth clay, lacking grog, is more susceptible to deformation and cracking, resulting in lower structural integrity under stress. The inclusion of grog in clay bodies significantly improves resistance to thermal shock and mechanical wear, making grogged clay ideal for functional ceramics and sculptural works requiring longevity.

Ideal Uses for Grogged Clay

Grogged clay contains pre-fired clay particles that enhance its structural strength and reduce shrinkage during firing, making it ideal for large-scale pottery, sculpture, and functional ware subjected to thermal stress. Its textured composition improves workability and prevents warping or cracking in kiln-dried or high-fire ceramics. Artists and potters prefer grogged clay for projects requiring durability and stability, such as wheel-thrown vessels, architectural ceramics, and textured surface finishes.

Ideal Uses for Smooth Clay

Smooth clay features a refined texture ideal for detailed pottery and sculpting projects that require a polished finish. Its lack of grog particles allows for delicate shaping and smooth surfaces, making it perfect for fine art ceramics, decorative pieces, and intricate molds. This clay type is preferred when a sleek, glossy, or painted surface is desired after firing.

Firing Behavior and Shrinkage Differences

Grogged clay contains pre-fired clay particles that reduce shrinkage and improve thermal shock resistance during firing, making it less prone to cracking compared to smooth clay. Smooth clay, lacking grog, exhibits higher shrinkage rates as water evaporates and the clay particles fuse, which increases the risk of warping and cracking. The presence of grog in grogged clay also facilitates better heat distribution, resulting in more uniform firing behavior and dimensional stability.

Surface Finish and Glazing Considerations

Grogged clay contains coarse particles that create a rough surface finish, ideal for textured pottery and improved glaze adhesion due to increased surface area. Smooth clay has a fine, even texture resulting in a sleek, polished surface but may require additional surface scoring or slip application for glaze to adhere properly. Selecting grogged or smooth clay influences not only the tactile quality of the final product but also the effectiveness and appearance of glazing.

Choosing the Right Clay for Your Pottery Project

Grogged clay contains small, pre-fired particles that improve texture and reduce shrinkage, making it ideal for larger or more intricate pottery projects requiring durability and reduced cracking. Smooth clay offers a fine, even consistency, perfect for detailed hand-building or delicate pieces where a refined surface finish is desired. Selecting the right clay depends on your project's needs for strength, texture, and the level of detail in your pottery design.

Grogged Clay vs Smooth Clay Infographic

materialdif.com

materialdif.com