Engobe and underglaze are both ceramic coatings used to decorate clay pets, offering unique finishes and effects. Engobe is a slip-based coating that can be applied to leather-hard clay for a matte or satin surface, often created by adding clay and colorants, while underglaze consists of colored pigments suspended in a water-based medium applied to bisque-fired clay, allowing for precise designs and vibrant colors. Both materials enhance the aesthetic appeal of clay pets but require different application techniques and firing processes to achieve optimal results.

Table of Comparison

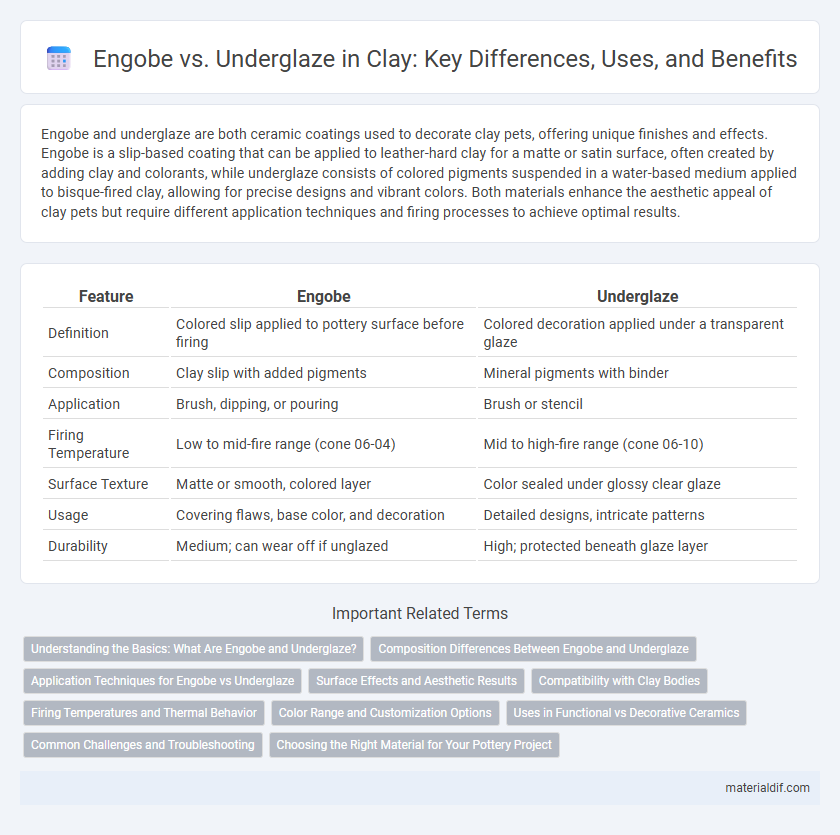

| Feature | Engobe | Underglaze |

|---|---|---|

| Definition | Colored slip applied to pottery surface before firing | Colored decoration applied under a transparent glaze |

| Composition | Clay slip with added pigments | Mineral pigments with binder |

| Application | Brush, dipping, or pouring | Brush or stencil |

| Firing Temperature | Low to mid-fire range (cone 06-04) | Mid to high-fire range (cone 06-10) |

| Surface Texture | Matte or smooth, colored layer | Color sealed under glossy clear glaze |

| Usage | Covering flaws, base color, and decoration | Detailed designs, intricate patterns |

| Durability | Medium; can wear off if unglazed | High; protected beneath glaze layer |

Understanding the Basics: What Are Engobe and Underglaze?

Engobe is a clay slip applied to pottery surfaces before firing, creating a smooth, colored base that can be manipulated for texture or decoration. Underglaze is a specialized ceramic colorant used under a transparent glaze, offering precise designs and vibrant colors that remain stable during firing. Both techniques enhance the aesthetic and functional qualities of ceramic pieces by allowing artists to customize surface appearance and texture.

Composition Differences Between Engobe and Underglaze

Engobe is a slip made primarily of clay, water, and finely ground oxides or colorants, designed to adhere smoothly to leather-hard or bisque-fired clay surfaces. Underglaze consists of a combination of clay, pigments, and fluxes, formulated to maintain vivid colors after firing and to fuse seamlessly under a clear glaze. The key compositional difference lies in engobe's higher clay content for texture and adhesion, while underglaze balances pigments and flux for color stability and surface finish.

Application Techniques for Engobe vs Underglaze

Engobe is typically applied in a thicker layer using brushing, dipping, or pouring techniques, allowing for textured surfaces and subtle color variations on greenware or bisque-fired clay. Underglaze, applied with fine brushes or sponges, offers precision for detailed patterns and smooth, even color coverage, suitable for both greenware and bisque. Both materials require careful timing for application to avoid peeling or cracking during firing.

Surface Effects and Aesthetic Results

Engobe creates a matte or satin surface with subtle texture variations that enhance the clay body's natural look, offering a soft, organic aesthetic perfect for rustic or traditional pottery. Underglaze provides vibrant, precise color application that remains stable under clear glaze, allowing for detailed patterns and sharp designs with a smooth, glossy finish. Both materials interact with glaze differently, where engobe's porous texture absorbs more glaze, often muting colors, while underglaze fuses seamlessly, preserving brightness and fine details.

Compatibility with Clay Bodies

Engobe is compatible with a wide range of clay bodies due to its lower firing temperature and porous nature, allowing it to bond effectively without causing surface defects. Underglaze, designed to withstand higher firing temperatures, adheres best to stoneware and porcelain, ensuring color stability and reduced risk of peeling or cracking. Matching the firing temperature and shrinkage rates of the clay body with the chosen coating is crucial for optimal compatibility and durability.

Firing Temperatures and Thermal Behavior

Engobe typically fires at a lower temperature range of cone 04 to cone 6 (approximately 1940degF to 2232degF), allowing it to remain matte and slightly porous, while underglaze is formulated to withstand higher temperatures often reaching cone 6 to cone 10 (2232degF to 2345degF) without losing color vibrancy. Thermal expansion compatibility is crucial; engobe's lower firing range makes it ideal for pottery with mid-range clay bodies, whereas underglaze's higher firing tolerance suits stoneware and porcelain that mature at elevated temperatures. Understanding the firing temperature and thermal behavior differences ensures durability and prevents surface defects like crazing or peeling in finished ceramic pieces.

Color Range and Customization Options

Engobe offers a broad color range with subtle, earthy tones ideal for natural finishes, while underglaze provides vibrant, intense colors for detailed and precise designs. Customization options in engobe allow for layered textures and translucency effects, whereas underglaze supports fine line work and sharp, graphic patterns. Both materials can be mixed with slips or stains to expand color possibilities, but underglaze generally delivers more consistent and saturated hues.

Uses in Functional vs Decorative Ceramics

Engobe, a liquid clay slip, is primarily used in functional ceramics to create a smooth, durable surface that can adhere well to varied clay bodies, enhancing both texture and color without compromising the vessel's utility. Underglaze offers more precise and vibrant decoration, favored in decorative ceramics for intricate designs and patterns that remain visible under a clear glaze, allowing artists to achieve detailed visual effects. Functional ceramics benefit from engobe's ability to mask imperfections and improve surface quality, while decorative pieces often utilize underglaze for its rich pigmentation and compatibility with complex artistic motifs.

Common Challenges and Troubleshooting

Engobe and underglaze often present challenges such as color unpredictability and surface cracking due to differences in clay body absorption and firing temperatures. Common troubleshooting techniques include testing on sample tiles, adjusting wash thickness, and ensuring proper drying times to prevent defects. Understanding the chemical composition and firing range of each material helps optimize application and achieve consistent results.

Choosing the Right Material for Your Pottery Project

Engobe offers a versatile option for pottery projects by providing a smooth, colored slip that adheres well to leather-hard clay and enhances texture and depth, making it ideal for surface decoration and subtle color effects. Underglaze, known for its vibrant, opaque colors, is perfect for detailed designs and layering, maintaining color clarity after firing and allowing for precise application on both bisqueware and leather-hard clay. Selecting between engobe and underglaze depends on the desired finish, color intensity, and firing temperature compatibility with the clay body to achieve optimal results in your pottery project.

Engobe vs Underglaze Infographic

materialdif.com

materialdif.com