Mason stain offers vibrant, consistent color with strong resistance to fading, making it ideal for detailed ceramic designs on clay pets. Oxide stain provides a more natural, earthy tone that enhances the texture and raw appearance of clay surfaces. Choosing between Mason stain and oxide stain depends on whether a bright finish or a rustic, organic look is desired for decorating clay pets.

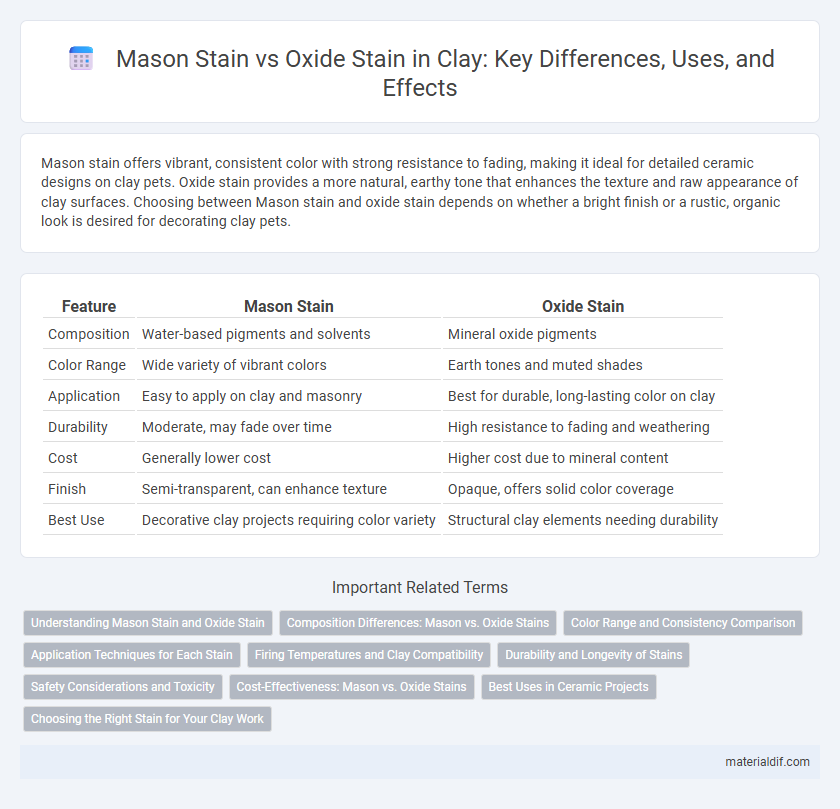

Table of Comparison

| Feature | Mason Stain | Oxide Stain |

|---|---|---|

| Composition | Water-based pigments and solvents | Mineral oxide pigments |

| Color Range | Wide variety of vibrant colors | Earth tones and muted shades |

| Application | Easy to apply on clay and masonry | Best for durable, long-lasting color on clay |

| Durability | Moderate, may fade over time | High resistance to fading and weathering |

| Cost | Generally lower cost | Higher cost due to mineral content |

| Finish | Semi-transparent, can enhance texture | Opaque, offers solid color coverage |

| Best Use | Decorative clay projects requiring color variety | Structural clay elements needing durability |

Understanding Mason Stain and Oxide Stain

Mason stain is a water-based pigment made from finely ground metal oxides, providing long-lasting color that penetrates deeply into clay for vibrant, consistent hues. Oxide stain, composed of natural metal oxide powders, offers durable, color-fast finishes and is typically used to achieve earthy or muted tones in ceramic projects. Both stains enhance the aesthetic of clay surfaces but differ in application techniques and color intensity.

Composition Differences: Mason vs. Oxide Stains

Mason stains primarily consist of synthetic pigments combined with binders and solvents, providing a consistent color that penetrates the clay surface evenly. Oxide stains are made from natural metal oxides such as iron, cobalt, and manganese, which create more earthy, variegated hues due to their mineral composition. The chemical stability and particle size of oxide stains contribute to their durability and subtle color shifts during firing compared to the more uniform finish of mason stains.

Color Range and Consistency Comparison

Mason stain offers a broader and more vibrant color range compared to oxide stain, providing hues from deep blues to rich reds that oxide stains cannot achieve. Oxide stains deliver more consistent earth-toned colors such as rust, ochre, and sienna, ensuring uniformity in large clay projects. This difference in color variety and consistency makes mason stains ideal for artistic applications, while oxide stains suit architectural and structural clay elements requiring stable coloration.

Application Techniques for Each Stain

Mason stains require application on porous, unsealed clay surfaces using brushes or sprayers to achieve deep, variegated color effects that penetrate the material. Oxide stains are typically applied as a dry powder or mixed with water, then dusted or brushed onto the clay surface before firing, creating a more consistent and stable color throughout the clay body. Precise timing, surface preparation, and firing temperature are crucial for both stain types to ensure optimal adhesion and color development.

Firing Temperatures and Clay Compatibility

Mason stains offer vibrant colors that remain stable across a wide range of firing temperatures, typically from cone 06 to cone 10, making them compatible with various clay bodies including earthenware, stoneware, and porcelain. Oxide stains, derived from natural metal oxides, tend to produce more muted tones and require precise firing temperature control, often suited for mid to high-fire clays such as stoneware and porcelain fired between cone 5 to cone 10. Compatibility with clay varies as Mason stains chemically bond uniformly with higher-temperature-fired clays, while oxide stains may respond differently depending on the clay's flux content and firing curve.

Durability and Longevity of Stains

Mason stain offers deeper penetration into clay surfaces, resulting in enhanced durability and longer-lasting color retention compared to oxide stain. Oxide stain typically provides a surface-level coloration that may fade or wear over time when exposed to weathering and abrasion. Choosing Mason stain ensures superior longevity for clay materials in both interior and exterior applications.

Safety Considerations and Toxicity

Mason stains contain pigments bound with resin, generally exhibiting lower toxicity and emitting fewer volatile organic compounds (VOCs), making them safer for indoor use compared to oxide stains. Oxide stains consist primarily of iron oxide particles, which are non-toxic and inert but may pose inhalation risks as fine dust during application and sanding. Proper handling with protective gear and adequate ventilation is essential to minimize exposure to dust and fumes from both stain types.

Cost-Effectiveness: Mason vs. Oxide Stains

Mason stains typically offer greater cost-effectiveness compared to oxide stains due to their lower material and application expenses. Oxide stains, while more vibrant and durable, often require higher upfront investment and specialized labor, increasing overall project costs. Choosing Mason stain can reduce budget impact without significantly compromising aesthetic quality in clay applications.

Best Uses in Ceramic Projects

Mason stains provide vibrant, consistent colors ideal for detailed glazing and surface decoration in ceramics, offering high stability and resistance to heat during firing. Oxide stains, composed of metal oxides like iron or cobalt, are best for achieving earthy, natural tones and are often used for underglaze coloring and textural effects. Choosing between Mason and oxide stains depends on the desired finish, firing temperature, and the specific aesthetic goals of the ceramic project.

Choosing the Right Stain for Your Clay Work

Mason stain offers vibrant, consistent colors by penetrating deep into clay, ideal for detailed or decorative work that requires durability. Oxide stain, made from natural metal oxides, provides earthy, muted tones that enhance clay's organic texture and are preferred for rustic or traditional pottery styles. Choosing between mason and oxide stains depends on the desired finish, color intensity, and firing temperature compatibility in your clay projects.

Mason Stain vs Oxide Stain Infographic

materialdif.com

materialdif.com