Raku clay is specially formulated to withstand rapid temperature changes during the raku firing process, making it ideal for creating unique ceramic pieces with crackled surfaces and vibrant glaze effects. Stoneware clay is denser and fired at higher temperatures, resulting in durable, non-porous pottery suitable for functional items like dishes and mugs. Choosing between raku and stoneware clay depends on whether the final piece prioritizes artistic texture and aesthetic or functional strength and durability.

Table of Comparison

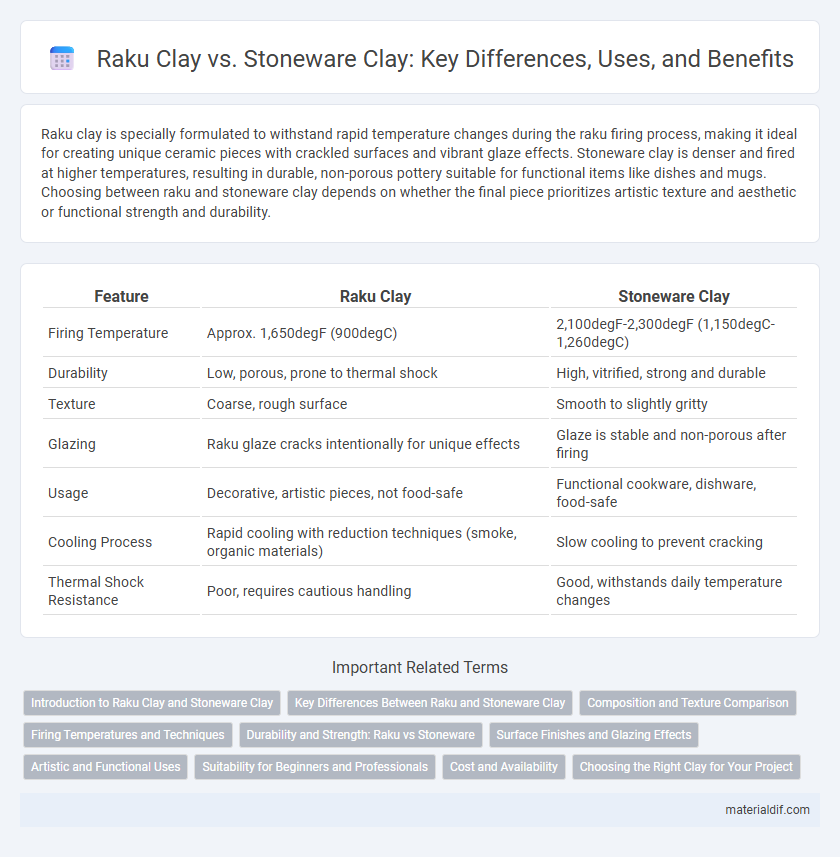

| Feature | Raku Clay | Stoneware Clay |

|---|---|---|

| Firing Temperature | Approx. 1,650degF (900degC) | 2,100degF-2,300degF (1,150degC-1,260degC) |

| Durability | Low, porous, prone to thermal shock | High, vitrified, strong and durable |

| Texture | Coarse, rough surface | Smooth to slightly gritty |

| Glazing | Raku glaze cracks intentionally for unique effects | Glaze is stable and non-porous after firing |

| Usage | Decorative, artistic pieces, not food-safe | Functional cookware, dishware, food-safe |

| Cooling Process | Rapid cooling with reduction techniques (smoke, organic materials) | Slow cooling to prevent cracking |

| Thermal Shock Resistance | Poor, requires cautious handling | Good, withstands daily temperature changes |

Introduction to Raku Clay and Stoneware Clay

Raku clay is a porous, low-fire clay specially formulated to withstand rapid cooling during the raku firing process, often containing grog to reduce thermal shock. Stoneware clay is a dense, high-fire clay known for its durability and vitrification at temperatures between 1200degC and 1300degC, making it ideal for functional pottery. Both clays offer distinct firing properties, with raku clay suited for artistic, crackle-glaze effects, while stoneware clay provides strength and water resistance for everyday use.

Key Differences Between Raku and Stoneware Clay

Raku clay is porous and designed to withstand rapid thermal changes during the raku firing process, making it ideal for low-temperature, fast firings with dramatic crackle effects. Stoneware clay is denser and vitrifies at higher temperatures, resulting in durable, non-porous ceramics suited for functional ware and long-term use. Key differences include thermal shock resistance in raku clay versus the strength and water resistance of stoneware clay.

Composition and Texture Comparison

Raku clay is characterized by its porous, grog-heavy composition, which allows for rapid heating and cooling during the raku firing process, offering a rough texture and enhanced thermal shock resistance. Stoneware clay, in contrast, features a denser, finer-grained composition with a higher vitrification level that produces a smooth, durable, and less porous texture suited for functional pottery. The mineral content in raku clay includes a higher concentration of alumina and silica to withstand thermal stress, whereas stoneware clay's balanced feldspar, kaolin, and silica blend provides strength and resilience after high-temperature firing.

Firing Temperatures and Techniques

Raku clay typically fires at lower temperatures between 1,650degF to 1,945degF (900degC to 1063degC), allowing for rapid cooling and removal from the kiln while hot, which creates unique crackle effects. Stoneware clay requires higher firing temperatures, ranging from 2,190degF to 2,372degF (1,200degC to 1,300degC), resulting in a dense, vitrified, and durable ceramic body suitable for functional pottery. The Raku firing technique involves quick heating and thermal shock cooling, whereas stoneware uses slow, controlled firing and cooling cycles to enhance strength and glaze maturation.

Durability and Strength: Raku vs Stoneware

Stoneware clay exhibits higher durability and strength compared to raku clay, making it ideal for functional pottery subjected to daily use and high-temperature firing. Raku clay, while prized for its unique, crackled aesthetic and rapid firing process, tends to be more porous and fragile, resulting in lower mechanical strength and vulnerability to thermal shock. Stoneware's dense, vitrified structure after firing ensures superior resistance to chipping and cracking under pressure and temperature variations.

Surface Finishes and Glazing Effects

Raku clay, known for its porous texture, interacts uniquely with glazes, producing unpredictable and often metallic or crackled surface finishes due to rapid cooling and reduction firing. Stoneware clay, being denser and less porous, supports a wide range of glaze applications, yielding durable, smooth, and uniformly glassy finishes ideal for functional ware. The thermal shock resistance of Raku contrasts with stoneware's ability to withstand high-temperature firings, influencing the final aesthetic and surface effects of each clay type.

Artistic and Functional Uses

Raku clay is prized for its ability to withstand rapid temperature changes, making it ideal for creating unique, crackled pottery with unpredictable artistic effects. Stoneware clay offers greater durability and strength, suitable for functional items like dinnerware and cookware that require long-term usability. Artists choose Raku for expressive, one-of-a-kind pieces, while stoneware is preferred for practical, everyday ceramics.

Suitability for Beginners and Professionals

Raku clay, characterized by its low firing temperature and porous nature, is ideal for beginners due to its ease of use and quick firing process, making it suitable for experimental and decorative pottery. Stoneware clay, fired at higher temperatures, offers greater strength and durability, preferred by professionals aiming for functional and robust ceramic pieces. Both clays provide unique advantages, with Raku favoring artistic expression and Stoneware supporting utility and longevity.

Cost and Availability

Raku clay is typically more expensive than stoneware clay due to its specialized composition designed for rapid thermal shock resistance. Stoneware clay is widely available in art supply stores and online, making it more accessible for beginners and large-scale projects. Cost-effective stoneware options range from $10 to $30 per 25-pound bag, whereas raku clay can cost upwards of $40 due to its unique materials and firing requirements.

Choosing the Right Clay for Your Project

Raku clay is porous and designed to withstand rapid temperature changes during the raku firing process, making it ideal for decorative pieces that benefit from unique surface textures and crackle effects. Stoneware clay, characterized by its durability and vitrification at higher firing temperatures, is better suited for functional items like dinnerware and cookware that require strength and water resistance. Selecting the right clay depends on the project's firing method, desired finish, and functional requirements to ensure optimal performance and aesthetic appeal.

Raku Clay vs Stoneware Clay Infographic

materialdif.com

materialdif.com