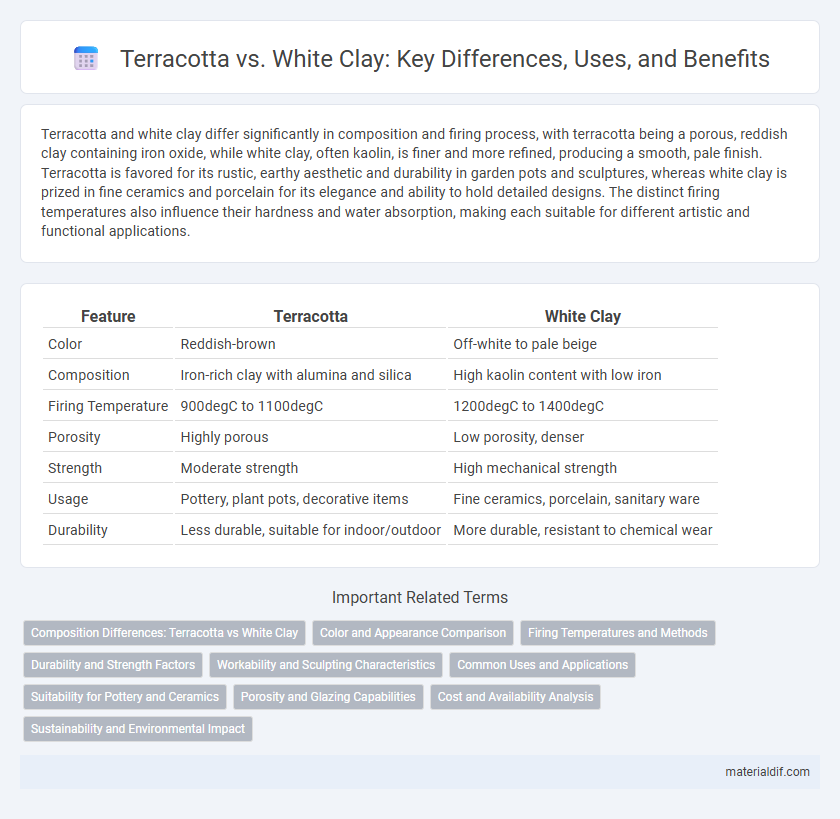

Terracotta and white clay differ significantly in composition and firing process, with terracotta being a porous, reddish clay containing iron oxide, while white clay, often kaolin, is finer and more refined, producing a smooth, pale finish. Terracotta is favored for its rustic, earthy aesthetic and durability in garden pots and sculptures, whereas white clay is prized in fine ceramics and porcelain for its elegance and ability to hold detailed designs. The distinct firing temperatures also influence their hardness and water absorption, making each suitable for different artistic and functional applications.

Table of Comparison

| Feature | Terracotta | White Clay |

|---|---|---|

| Color | Reddish-brown | Off-white to pale beige |

| Composition | Iron-rich clay with alumina and silica | High kaolin content with low iron |

| Firing Temperature | 900degC to 1100degC | 1200degC to 1400degC |

| Porosity | Highly porous | Low porosity, denser |

| Strength | Moderate strength | High mechanical strength |

| Usage | Pottery, plant pots, decorative items | Fine ceramics, porcelain, sanitary ware |

| Durability | Less durable, suitable for indoor/outdoor | More durable, resistant to chemical wear |

Composition Differences: Terracotta vs White Clay

Terracotta consists primarily of iron-rich clay, giving it a distinctive reddish-brown color due to high iron oxide content, while white clay, often kaolin, contains minimal iron oxide, resulting in its pale or white hue. The chemical composition of terracotta includes significant amounts of silica, alumina, and iron oxides, whereas white clay is dominated by kaolinite, silica, and alumina with negligible iron levels. These compositional differences affect firing temperatures, porosity, and final durability, making terracotta more porous and white clay denser and more refined.

Color and Appearance Comparison

Terracotta clay boasts a warm, earthy reddish-brown hue stemming from its iron oxide content, making it ideal for rustic pottery and decorative items with a natural finish. In contrast, white clay features a pale, creamy to bright white color that provides a smooth, refined surface favored for porcelain, fine ceramics, and detailed sculpting. The distinct color contrast between terracotta's warm tones and white clay's neutral shade influences artistic choices and the visual impact of finished ceramic pieces.

Firing Temperatures and Methods

Terracotta typically fires at lower temperatures, around 1,000 to 1,150degC, using oxidation firing methods that produce its characteristic reddish-orange color due to iron content. White clay, often kaolin-based, requires higher firing temperatures ranging from 1,200 to 1,400degC and can be fired in oxidation or reduction atmospheres to achieve a porcelain-like, white finish. The choice of firing temperature and method directly impacts the clay's durability, porosity, and color outcome.

Durability and Strength Factors

Terracotta, composed of porous red clay fired at lower temperatures, offers moderate durability and strength suitable for decorative items and garden pottery but is prone to chipping and erosion under heavy use. White clay, often kaolin or porcelain clay, undergoes high-temperature firing resulting in a denser, harder material with superior strength and resistance to cracking, making it ideal for fine ceramics and functional ware. The mineral composition and firing process are key factors influencing terracotta's lower durability compared to the robust, compact structure of white clay.

Workability and Sculpting Characteristics

Terracotta clay, known for its iron-rich composition, offers excellent plasticity and is highly workable, making it ideal for hand-building and detailed sculpting. White clay, often porcelain or kaolin-based, has a finer texture and firmer consistency, providing smooth surfaces but requiring more skill to prevent cracking during sculpting. Both clays respond uniquely to moisture and firing temperatures, influencing their suitability for different artistic techniques.

Common Uses and Applications

Terracotta clay is commonly used for pottery, roofing tiles, and sculptures due to its porous nature and warm reddish-brown color, which enhances aesthetic appeal in garden planters and decorative items. White clay, often identified as kaolin, finds extensive applications in porcelain production, cosmetics, and paper coating because of its fine texture and high purity, providing a smooth, durable finish. Both clays play crucial roles in ceramics, but their distinct physical properties dictate their specific uses across art, industry, and manufacturing.

Suitability for Pottery and Ceramics

Terracotta clay, characterized by its iron-rich composition and reddish-brown hue, is ideal for rustic pottery and outdoor ceramics due to its porous nature and strong firing properties. White clay, often kaolin-based, excels in fine ceramics and porcelain because of its purity, smooth texture, and high plasticity, allowing for detailed work and a delicate finish. Potters choose terracotta for its durability and earthy aesthetic, while white clay is preferred for refined, translucent pieces requiring a high level of precision.

Porosity and Glazing Capabilities

Terracotta clay exhibits high porosity, allowing it to absorb water easily, which necessitates glazing to create a waterproof surface. White clay, with its low porosity, is less absorbent and provides a smooth surface ideal for detailed glazing and fine finishes. These differences make terracotta suitable for rustic, breathable ware, while white clay is preferred for refined, glossy ceramics.

Cost and Availability Analysis

Terracotta clay is generally more affordable and widely available, making it a popular choice for large-scale pottery and sculpting projects. White clay, often composed of kaolin, tends to be more expensive due to its purity and refined texture, and it is less commonly found in local markets. The cost differential reflects the processing requirements and the regional availability of raw materials, influencing artists' decisions based on budget and project scope.

Sustainability and Environmental Impact

Terracotta, made from natural red clay fired at lower temperatures, exhibits a lower carbon footprint compared to white clay, which requires higher firing temperatures and additional processing that increase energy consumption. The porous nature of terracotta enhances biodegradability and reduces long-term environmental impact, whereas white clay ceramics often incorporate chemical additives affecting recyclability. Sustainable sourcing of terracotta from abundant clay deposits further minimizes ecological disturbance, making it a more eco-friendly choice in pottery and construction applications.

Terracotta vs White Clay Infographic

materialdif.com

materialdif.com