Low fire clay typically matures at temperatures between cone 06 and cone 04 (1828degF to 1940degF), offering vivid colors and porous surfaces ideal for decorative pieces. High fire clay matures at temperatures above cone 8 (2300degF), resulting in a denser, more durable, and vitrified final product suitable for functional ware. Choosing between low fire and high fire depends on the balance between aesthetic preferences and strength requirements.

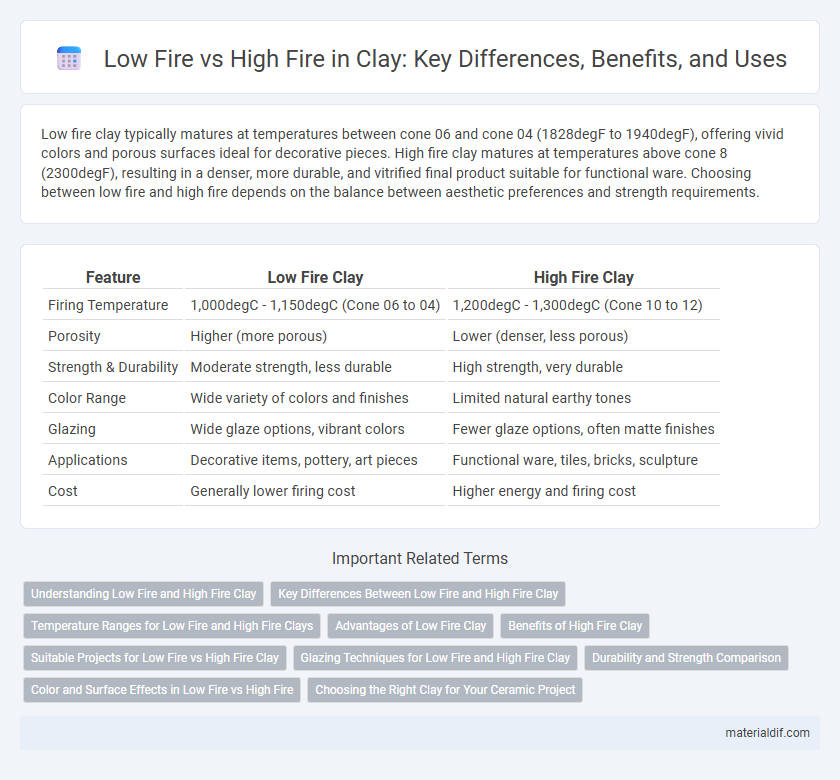

Table of Comparison

| Feature | Low Fire Clay | High Fire Clay |

|---|---|---|

| Firing Temperature | 1,000degC - 1,150degC (Cone 06 to 04) | 1,200degC - 1,300degC (Cone 10 to 12) |

| Porosity | Higher (more porous) | Lower (denser, less porous) |

| Strength & Durability | Moderate strength, less durable | High strength, very durable |

| Color Range | Wide variety of colors and finishes | Limited natural earthy tones |

| Glazing | Wide glaze options, vibrant colors | Fewer glaze options, often matte finishes |

| Applications | Decorative items, pottery, art pieces | Functional ware, tiles, bricks, sculpture |

| Cost | Generally lower firing cost | Higher energy and firing cost |

Understanding Low Fire and High Fire Clay

Low fire clay matures at temperatures between 1,820degF and 2,100degF (Cone 01 to Cone 04), resulting in porous, lightweight ceramics ideal for decorative pottery and earthenware. High fire clay requires firing above 2,192degF (Cone 10 and up), producing dense, vitrified, and durable stoneware or porcelain that withstands daily use and outdoor conditions. The choice between low fire and high fire clay affects the final piece's strength, texture, and glaze compatibility, guiding potters toward specific functional or aesthetic outcomes.

Key Differences Between Low Fire and High Fire Clay

Low fire clay matures at temperatures between 1,820degF and 2,100degF, resulting in a porous and lighter body ideal for vibrant glazes and intricate surface details. High fire clay matures at temperatures from 2,192degF to 2,372degF, producing a denser, stronger, and more vitrified ceramic that is suitable for functional stoneware and porcelain. The key differences lie in temperature thresholds, firing duration, durability, porosity, and the types of glazes that can be effectively used.

Temperature Ranges for Low Fire and High Fire Clays

Low fire clays typically mature at temperatures between 1,820degF and 2,100degF (980degC to 1,150degC), offering bright colors and porous finished surfaces ideal for decorative pottery. High fire clays mature at much higher temperatures ranging from 2,300degF to 2,400degF (1,260degC to 1,320degC), producing denser, more durable ceramics suitable for stoneware and porcelain. Understanding these temperature ranges is crucial for selecting the right clay type to ensure optimal hardness, durability, and aesthetic qualities in finished ceramic pieces.

Advantages of Low Fire Clay

Low fire clay offers distinct advantages including faster firing cycles and lower energy consumption, making it cost-effective for both hobbyists and professionals. It allows for vibrant, bright glazes due to its compatible lower temperature glaze formulations, enhancing artistic expression and surface texture variety. The reduced thermal stress during firing also decreases the risk of cracking and warping, resulting in more durable finished pieces.

Benefits of High Fire Clay

High fire clay, fired at temperatures above 2300degF (1260degC), offers superior durability and strength compared to low fire clay, making it ideal for functional pottery and architectural ceramics. Its dense vitrification process enhances resistance to water, heat, and chemicals, ensuring long-lasting performance and minimal porosity. This type of clay also produces a more uniform color and texture, contributing to aesthetically pleasing and structurally sound ceramic pieces.

Suitable Projects for Low Fire vs High Fire Clay

Low fire clay is ideal for detailed sculptural projects, decorative pottery, and beginner ceramics due to its lower firing temperature, which preserves bright glaze colors and fine textures. High fire clay suits functional ware like dinnerware, teapots, and outdoor tiles because of its increased durability, vitrification, and resistance to thermal shock. Artists often choose low fire clay for vibrant, detailed pieces, while high fire clay is preferred for sturdy, utilitarian objects.

Glazing Techniques for Low Fire and High Fire Clay

Low fire clay glazing techniques often utilize bright, vibrant colors and more reactive glazes that melt at lower temperatures, creating glossy, smooth finishes with intricate surface textures. High fire clay glazes require formulations that can withstand higher kiln temperatures, resulting in durable, often matte or satin surfaces with subtle color variations due to the longer firing cycle and chemical interactions. Selecting appropriate glaze materials for low fire or high fire clay influences the final appearance, texture, and strength, with low fire glazes favoring decorative effects and high fire glazes emphasizing functionality and resilience.

Durability and Strength Comparison

Low fire clay, typically fired between 1,820degF and 2,100degF (1,000degC to 1,150degC), results in ceramics that are more porous and less durable due to incomplete vitrification. High fire clay, fired above 2,192degF (1,200degC), achieves a glass-like, vitrified surface making it significantly stronger and more resistant to water and physical wear. The increased density and hardness of high fire ceramics make them ideal for functional ware requiring long-term durability and strength.

Color and Surface Effects in Low Fire vs High Fire

Low fire clay typically produces brighter and more varied colors due to lower vitrification temperatures that preserve the clay's natural hues and glazes' vibrancy. High fire clay results in more subdued, earthy tones as the intense heat melts and fuses the materials, creating dense, durable surfaces with muted, often glossy finishes. Surface effects in low fire can include glossy, matte, or crystalline glazes, whereas high fire surfaces often develop rich textures and depth from the partial melting and interaction of minerals.

Choosing the Right Clay for Your Ceramic Project

Low fire clays, typically fired between 1,820degF and 2,100degF, offer vibrant glaze colors and are ideal for detailed, decorative pieces, while high fire clays, fired above 2,300degF, provide greater durability and strength suited for functional ware. Choosing the right clay depends on the desired finish and use; porcelain and stoneware clays endure high fire temperatures for toughness, whereas earthenware clays suit low fire projects with bright glazing options. Understanding firing temperatures and clay properties ensures optimal results for both aesthetic and practical ceramic applications.

Low Fire vs High Fire Infographic

materialdif.com

materialdif.com