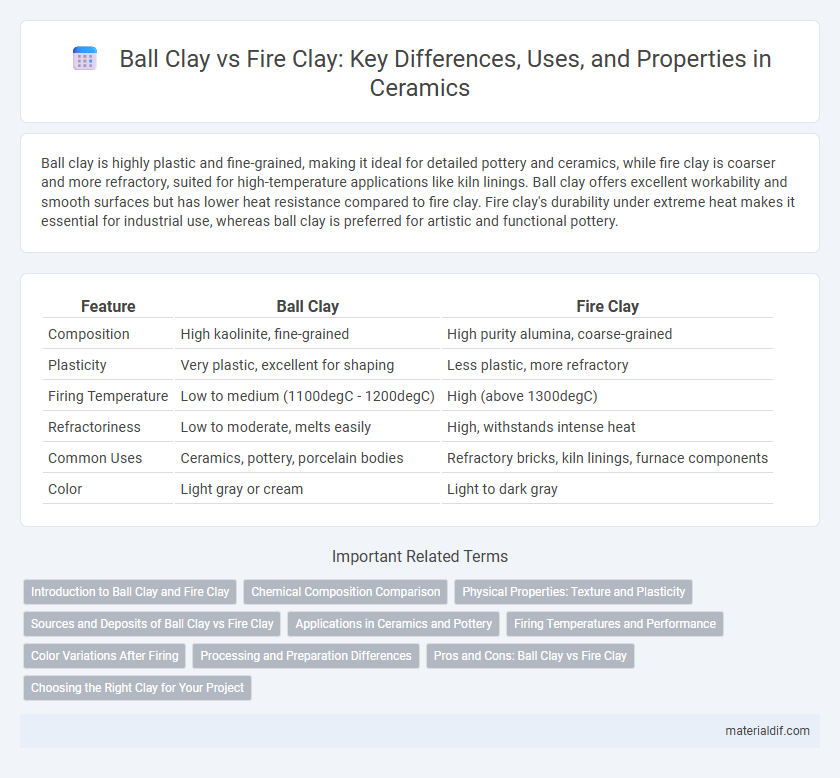

Ball clay is highly plastic and fine-grained, making it ideal for detailed pottery and ceramics, while fire clay is coarser and more refractory, suited for high-temperature applications like kiln linings. Ball clay offers excellent workability and smooth surfaces but has lower heat resistance compared to fire clay. Fire clay's durability under extreme heat makes it essential for industrial use, whereas ball clay is preferred for artistic and functional pottery.

Table of Comparison

| Feature | Ball Clay | Fire Clay |

|---|---|---|

| Composition | High kaolinite, fine-grained | High purity alumina, coarse-grained |

| Plasticity | Very plastic, excellent for shaping | Less plastic, more refractory |

| Firing Temperature | Low to medium (1100degC - 1200degC) | High (above 1300degC) |

| Refractoriness | Low to moderate, melts easily | High, withstands intense heat |

| Common Uses | Ceramics, pottery, porcelain bodies | Refractory bricks, kiln linings, furnace components |

| Color | Light gray or cream | Light to dark gray |

Introduction to Ball Clay and Fire Clay

Ball clay is a highly plastic, fine-grained sedimentary clay composed mainly of kaolinite, used for its excellent workability and strength after firing. Fire clay is a refractory clay with high alumina content, resistant to high temperatures, making it suitable for kiln linings and firebricks. Both clays serve different industrial purposes, with ball clay favored in ceramics for its plasticity and fire clay chosen for heat-resistant applications.

Chemical Composition Comparison

Ball clay primarily consists of kaolinite (around 50-80%), along with mica and quartz, exhibiting high plasticity and refined particle size that enhance moldability. Fire clay contains higher amounts of alumina (Al2O3) typically between 30-40% and silica (SiO2) ranging from 35-45%, contributing to its refractory properties and resistance to high temperatures. The chemical composition difference results in ball clay being ideal for casting and shaping, while fire clay withstands extreme heat in kiln linings and firebrick production.

Physical Properties: Texture and Plasticity

Ball clay exhibits a very fine texture and high plasticity, making it ideal for shaping and molding in pottery and ceramics. Fire clay has a coarser texture and lower plasticity, which enhances its heat resistance and structural strength in refractory applications. Both types differ significantly in particle size and workability, influencing their specific uses in industrial and artistic processes.

Sources and Deposits of Ball Clay vs Fire Clay

Ball clay deposits primarily originate from sedimentary basins, with major sources including the UK, the USA, and Thailand, where they consist of fine-grained, highly plastic kaolinite-rich clay suitable for ceramics. Fire clay deposits, found mainly in coal measures and sedimentary rock formations in regions such as the UK, USA, and Germany, contain refractory minerals like kaolinite and mullite, enabling high-temperature resistance. Unlike ball clay, fire clay is often mined from deeper strata associated with fire-resistant firebrick manufacturing.

Applications in Ceramics and Pottery

Ball clay possesses high plasticity and fine particle size, making it ideal for smooth, detailed ceramic ware such as porcelain and fine china due to its excellent workability and strength after firing. Fire clay, known for its refractory properties and higher alumina content, is predominantly used in heat-resistant applications like kiln linings, firebricks, and industrial ceramics that demand high thermal stability. While ball clay enhances the aesthetic and functional qualities of delicate pottery, fire clay provides durability and resistance in high-temperature environments.

Firing Temperatures and Performance

Ball clay fires at lower temperatures, typically between 1100degC and 1200degC, resulting in a smooth, plastic texture ideal for fine ceramics and pottery. Fire clay withstands much higher firing temperatures, often up to 1400degC or more, offering superior heat resistance and durability for industrial applications and refractory products. The difference in firing temperatures directly impacts their performance, with ball clay favored for workability and finish, while fire clay excels in strength and thermal stability.

Color Variations After Firing

Ball clay typically fires to a creamy white or buff color with a smooth, plastic texture, making it ideal for fine ceramics and porcelain. Fire clay, known for its high refractory properties, often exhibits a range of colors from light gray to reddish-brown after firing, depending on impurities like iron oxides. These distinct color variations influence the choice between ball clay and fire clay in pottery and industrial applications requiring specific aesthetics or thermal resistance.

Processing and Preparation Differences

Ball clay undergoes extensive beneficiation processes including washing, screening, and deflocculation to enhance plasticity and fine particle content, making it ideal for ceramic bodies requiring smooth textures. Fire clay typically requires minimal processing, often just crushing and drying, as its primary use in refractory applications depends on its high refractory properties and coarse particle size. The preparation differences directly influence their respective industrial applications, with ball clay optimized for moldability and fire clay for heat resistance.

Pros and Cons: Ball Clay vs Fire Clay

Ball clay offers excellent plasticity and fine particle size, making it ideal for detailed ceramics and smooth surfaces, but it has lower refractoriness and strength compared to fire clay. Fire clay provides superior heat resistance and durability, suitable for high-temperature applications like refractory bricks, but it is less plastic and harder to mold. Choosing between ball clay and fire clay depends on the specific requirements for workability versus thermal performance.

Choosing the Right Clay for Your Project

Ball clay offers high plasticity and smooth texture ideal for detailed ceramics and porcelain, while fire clay provides superior heat resistance and durability for kiln linings and firebricks. Selecting the right clay depends on your project's requirements for shaping flexibility versus thermal endurance. For sculpting fine pottery, ball clay is preferred, whereas fire clay suits high-temperature applications.

Ball Clay vs Fire Clay Infographic

materialdif.com

materialdif.com