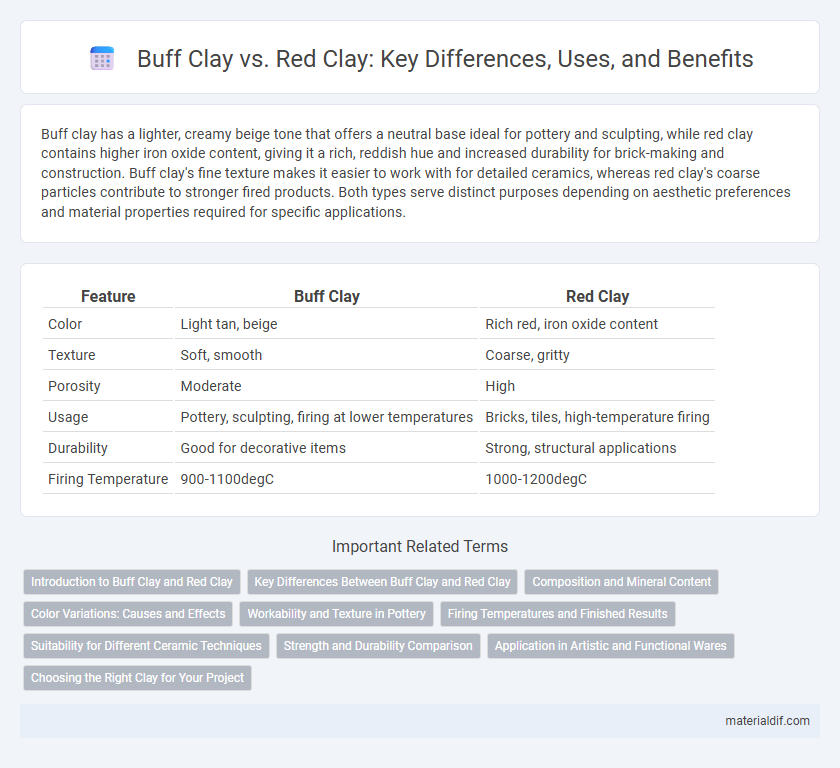

Buff clay has a lighter, creamy beige tone that offers a neutral base ideal for pottery and sculpting, while red clay contains higher iron oxide content, giving it a rich, reddish hue and increased durability for brick-making and construction. Buff clay's fine texture makes it easier to work with for detailed ceramics, whereas red clay's coarse particles contribute to stronger fired products. Both types serve distinct purposes depending on aesthetic preferences and material properties required for specific applications.

Table of Comparison

| Feature | Buff Clay | Red Clay |

|---|---|---|

| Color | Light tan, beige | Rich red, iron oxide content |

| Texture | Soft, smooth | Coarse, gritty |

| Porosity | Moderate | High |

| Usage | Pottery, sculpting, firing at lower temperatures | Bricks, tiles, high-temperature firing |

| Durability | Good for decorative items | Strong, structural applications |

| Firing Temperature | 900-1100degC | 1000-1200degC |

Introduction to Buff Clay and Red Clay

Buff clay is a pale yellow to light brown clay valued for its plasticity and smooth texture, commonly used in ceramics and pottery due to its fine particle size and high iron content. Red clay, rich in iron oxide, exhibits a distinctive deep red or reddish-brown hue and is favored for its durability and thermal resistance in construction and sculptural applications. Both buff and red clays differ significantly in color, mineral composition, and end-use characteristics, influencing their selection based on aesthetic and functional requirements.

Key Differences Between Buff Clay and Red Clay

Buff clay typically exhibits a pale yellowish-brown color due to lower iron oxide content, while red clay is rich in iron oxides, giving it a distinct reddish hue. Buff clay generally has a finer texture and better plasticity, making it ideal for pottery and sculpting, whereas red clay's higher iron content often results in greater hardness and durability. Moisture retention and drainage also differ, with buff clay retaining water more effectively, influencing its suitability for agricultural and construction purposes.

Composition and Mineral Content

Buff clay primarily consists of kaolinite and illite, with a higher concentration of iron oxides that give it a pale yellow to beige hue. Red clay contains a greater amount of hematite and other iron oxide minerals, which cause its characteristic reddish color and also contribute to its increased density. Both types of clay have varying levels of silica and aluminum oxides, affecting their plasticity and durability in ceramic and construction applications.

Color Variations: Causes and Effects

Buff clay exhibits a pale yellow to light brown hue due to iron hydroxides like goethite, while red clay's vivid red color results from higher concentrations of hematite, an iron oxide mineral. Variations in oxidation states and moisture content influence these color differences, directly affecting soil temperature regulation and water retention properties. These color-induced physical properties have significant implications for agricultural suitability and construction applications.

Workability and Texture in Pottery

Buff clay offers superior workability in pottery due to its smooth, fine texture, which allows for easier shaping and detailing. Red clay, with its coarser texture and higher iron content, provides a firmer grip but can be more challenging to manipulate. Both clays impact the final pottery finish, with buff clay producing smoother surfaces and red clay yielding a more rustic appearance.

Firing Temperatures and Finished Results

Buff clay typically fires at a slightly lower temperature range of 1,800degF to 2,100degF (982degC to 1,149degC), resulting in a light, creamy finish ideal for functional pottery and earthenware. Red clay requires higher firing temperatures, often between 2,200degF and 2,400degF (1,204degC to 1,316degC), producing a denser, more durable ceramic with a characteristic reddish hue favored in stoneware and terracotta. The different iron oxide content and firing temperatures significantly influence the hardness, porosity, and color outcomes of the finished ceramic pieces.

Suitability for Different Ceramic Techniques

Buff clay, known for its light, neutral color and fine texture, is ideal for wheel throwing and slip casting, offering excellent plasticity and smoothness that enhance detail work. Red clay, rich in iron oxide, suits hand-building techniques like coiling and slab construction due to its robust strength and earthy texture that improves structural integrity. Both clays cater to distinct ceramic techniques, with buff clay favored for precision and red clay preferred for sculptural and functional ware.

Strength and Durability Comparison

Buff clay exhibits higher compressive strength and better resistance to weathering than red clay due to its denser mineral composition and lower porosity. Red clay typically shows increased brittleness and is more susceptible to cracking under tensile stress, reducing its overall durability in construction applications. The strength-to-durability ratio of buff clay makes it preferable for structural uses requiring long-lasting performance.

Application in Artistic and Functional Wares

Buff clay, characterized by its light beige to yellowish color and smooth texture, is preferred in pottery for creating functional wares such as tableware and cookware due to its excellent durability and resistance to thermal shock. Red clay, rich in iron oxide, is favored by artists for sculptural and decorative pieces, offering a vibrant hue and a slightly porous surface that enhances glazing effects. Both clays serve distinct artistic and practical purposes, with buff clay excelling in everyday utility items and red clay thriving in aesthetic and ornamental creations.

Choosing the Right Clay for Your Project

Buff clay offers a neutral, light beige hue ideal for pottery requiring subtle earth tones and smooth textures, while red clay provides rich, warm coloration with high iron content perfect for rustic ceramics and sculptures. Selecting the right clay depends on your project's aesthetic goals, firing temperature, and durability needs, as buff clay generally fires at lower temperatures with less shrinkage compared to the more robust red clay. Understanding raw material composition and intended use ensures optimal results in both functional and artistic clay works.

Buff Clay vs Red Clay Infographic

materialdif.com

materialdif.com