Porcelain is a high-fired, vitrified clay known for its strength, translucency, and smooth, glass-like surface, often used in fine art and dinnerware. Terracotta is a porous, low-fired clay with a rustic, earthy appearance, commonly employed for pottery, flowerpots, and architectural elements. The choice between porcelain and terracotta depends on desired durability, finish, and usage, with porcelain offering a refined, delicate look and terracotta providing a warm, natural texture.

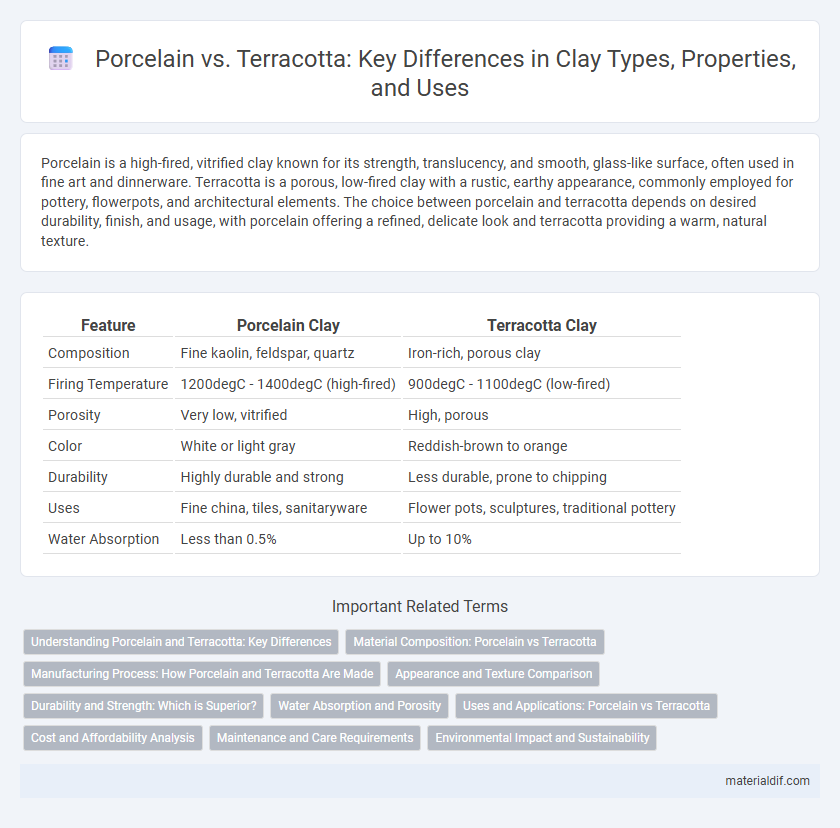

Table of Comparison

| Feature | Porcelain Clay | Terracotta Clay |

|---|---|---|

| Composition | Fine kaolin, feldspar, quartz | Iron-rich, porous clay |

| Firing Temperature | 1200degC - 1400degC (high-fired) | 900degC - 1100degC (low-fired) |

| Porosity | Very low, vitrified | High, porous |

| Color | White or light gray | Reddish-brown to orange |

| Durability | Highly durable and strong | Less durable, prone to chipping |

| Uses | Fine china, tiles, sanitaryware | Flower pots, sculptures, traditional pottery |

| Water Absorption | Less than 0.5% | Up to 10% |

Understanding Porcelain and Terracotta: Key Differences

Porcelain is a fine, white clay fired at extremely high temperatures, resulting in a dense, non-porous, and translucent material ideal for delicate ceramics and dishware. Terracotta, made from natural red or brown clay fired at lower temperatures, is porous and more rustic, commonly used for pottery, sculpture, and architectural decor. Key differences include firing temperature, porosity, color, and application, with porcelain prized for its durability and elegance, while terracotta is valued for its earthy texture and warmth.

Material Composition: Porcelain vs Terracotta

Porcelain is made from a refined clay mixed with kaolin, feldspar, and quartz, fired at extremely high temperatures around 1,200-1,400degC, resulting in a dense, vitrified, and non-porous material. Terracotta consists mainly of natural, unrefined clay with iron oxide, fired at lower temperatures between 900-1,100degC, producing a porous, reddish-brown ceramic. The compositional differences influence their strength, durability, and water absorption properties, with porcelain being harder and less porous than terracotta.

Manufacturing Process: How Porcelain and Terracotta Are Made

Porcelain is manufactured by firing refined kaolin clay at extremely high temperatures, typically between 1,200 and 1,400 degrees Celsius, resulting in a dense, vitrified, and translucent material. Terracotta is made from coarse, iron-rich clay that is fired at lower temperatures ranging from 900 to 1,100 degrees Celsius, producing a porous, reddish-brown ceramic. The key differences in temperature and clay refinement during the manufacturing process influence the durability, water resistance, and appearance of these ceramic materials.

Appearance and Texture Comparison

Porcelain features a smooth, glass-like surface with a translucent quality and a fine, dense texture that is often white or pale in color. Terracotta has a rougher, porous texture with a matte finish, typically showcasing earthy red or orange hues due to its iron-rich clay. The denser, vitrified nature of porcelain lends itself to a sleek and polished appearance, while terracotta's coarse, unglazed surface creates a rustic, natural look.

Durability and Strength: Which is Superior?

Porcelain offers greater durability and strength compared to terracotta due to its high firing temperature and denser composition, making it less porous and more resistant to chipping and cracking. Terracotta, while aesthetically warm and breathable, is more prone to damage from moisture and physical impacts because it is fired at lower temperatures and remains more porous. For applications demanding longevity and structural integrity, porcelain is the superior choice.

Water Absorption and Porosity

Porcelain exhibits low water absorption rates, typically below 0.5%, due to its dense, fine-grained structure and minimal porosity, making it highly water-resistant and ideal for durable ceramics. Terracotta, characterized by higher porosity and water absorption rates ranging from 6% to 15%, absorbs moisture readily, which affects its durability and makes it more susceptible to weathering. These differences in porosity and water absorption critically influence the suitability of porcelain and terracotta for various applications, especially where water exposure is a concern.

Uses and Applications: Porcelain vs Terracotta

Porcelain excels in fine tableware, intricate decorative objects, and dental ceramics due to its high density, durability, and smooth, non-porous surface. Terracotta is widely used for garden pots, sculptures, and architectural elements because of its porosity, rustic aesthetic, and ability to retain moisture. Porcelain suits applications requiring strength and water resistance, while terracotta is favored for breathability and traditional, earthy finishes.

Cost and Affordability Analysis

Porcelain clay is typically more expensive due to its refined composition and higher firing temperatures, making it less affordable for large-scale or casual projects. Terracotta, made from natural, coarse clay fired at lower temperatures, offers a budget-friendly option with wide availability and ease of use. Cost-effective terracotta suits decorative and functional purposes where durability and fine detail are less critical compared to the sleek, high-quality finish porcelain provides.

Maintenance and Care Requirements

Porcelain requires minimal maintenance due to its dense, non-porous structure, making it resistant to stains, scratches, and moisture. Terracotta is more porous and needs regular sealing to prevent water absorption and damage, while also requiring careful cleaning to avoid chipping. Proper care extends the lifespan of both materials, but porcelain's durability offers a lower-maintenance advantage for long-term use.

Environmental Impact and Sustainability

Porcelain, made from refined kaolin clay, requires high-temperature firing that consumes significant energy, contributing to a larger carbon footprint compared to terracotta, which is fired at lower temperatures. Terracotta's natural, porous composition allows for biodegradability and lower environmental impact, making it a more sustainable option in eco-friendly construction and pottery. Both materials rely on clay resources, but terracotta's simpler processing and lower energy demands support greater environmental sustainability.

Porcelain vs Terracotta Infographic

materialdif.com

materialdif.com