Short clay particles, measuring less than 0.002 mm, exhibit high plasticity and surface area, which enhances water retention and nutrient availability in soil. Long clay particles, although less common, influence soil structure by promoting aggregation and improving aeration. Understanding the differences between short and long clay particles is crucial for optimizing soil management and agricultural productivity.

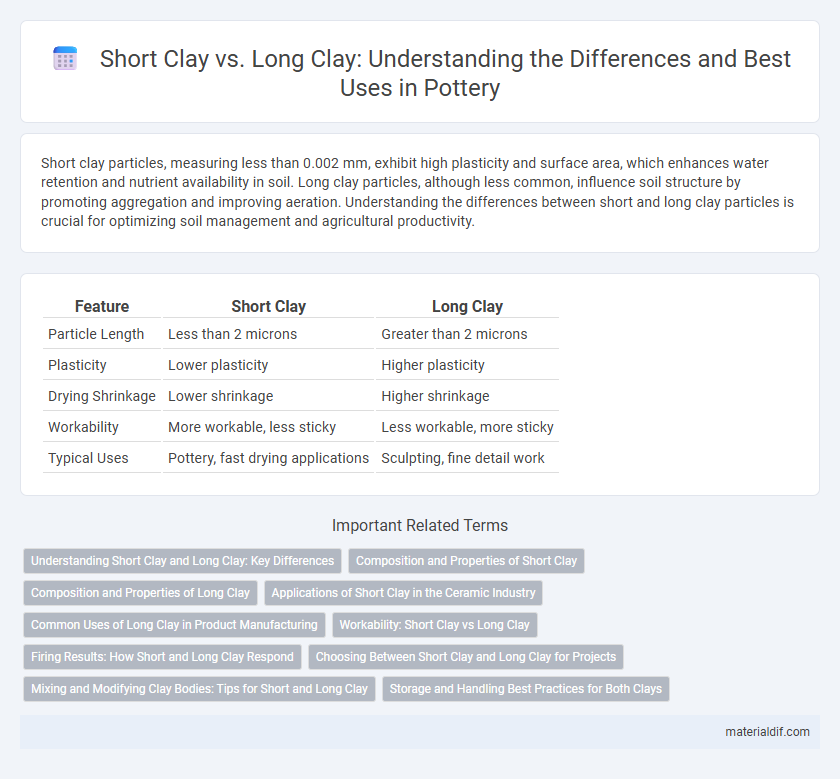

Table of Comparison

| Feature | Short Clay | Long Clay |

|---|---|---|

| Particle Length | Less than 2 microns | Greater than 2 microns |

| Plasticity | Lower plasticity | Higher plasticity |

| Drying Shrinkage | Lower shrinkage | Higher shrinkage |

| Workability | More workable, less sticky | Less workable, more sticky |

| Typical Uses | Pottery, fast drying applications | Sculpting, fine detail work |

Understanding Short Clay and Long Clay: Key Differences

Short clay particles have a smaller surface area and higher plasticity, making them ideal for shaping and molding in pottery and ceramics. Long clay particles exhibit greater fiber-like structures, providing increased strength and flexibility, useful in construction materials and reinforcing composites. Understanding the distinctions between short and long clay particles helps optimize their application in industrial and artistic contexts.

Composition and Properties of Short Clay

Short clay, characterized by its high plasticity and fine particle size, is primarily composed of kaolinite and montmorillonite minerals. Its compact structure results in low permeability, excellent water retention, and increased cohesiveness, making it ideal for pottery and structural applications. The high shrink-swell capacity distinguishes short clay from long clay, which contains more elongated particles and offers greater flexibility but less strength.

Composition and Properties of Long Clay

Long clay, characterized by elongated plate-like particles, typically consists of kaolinite or montmorillonite minerals, which contribute to its unique structural properties. Its extended particle shape enhances plasticity and water retention, making it ideal for ceramics and construction applications requiring high malleability and strength. The mineral composition of long clay also affects its durability and shrink-swell behavior, influencing performance in various environmental conditions.

Applications of Short Clay in the Ceramic Industry

Short clay, characterized by fine particles and uniform texture, is widely used in the ceramic industry for producing smooth, high-quality porcelain and fine china. Its excellent plasticity and workability enable the creation of intricate shapes and detailed designs, essential for decorative ceramics and sanitaryware. The short particle size also enhances the firing strength and reduces shrinkage, making it ideal for precision ceramic products.

Common Uses of Long Clay in Product Manufacturing

Long clay, characterized by its extended particle size, is widely used in ceramics and pottery for producing durable tiles and bricks. Its structure enhances mechanical strength and reduces shrinkage during firing, making it ideal for construction materials and heavy-duty products. Manufacturers also incorporate long clay in refractories and insulation products due to its thermal resistance and structural stability.

Workability: Short Clay vs Long Clay

Short clay particles exhibit higher workability due to their smaller size and reduced surface area, which allows for easier mixing and shaping. In contrast, long clay particles tend to create a denser network structure, resulting in lower workability and more resistance during molding processes. The particle shape and size distribution directly influence the plasticity and moisture retention, critical factors in determining the ease of handling different types of clay.

Firing Results: How Short and Long Clay Respond

Short clay particles, typically less than 2 microns, enhance firing results by promoting faster densification and a smoother surface finish due to their high plasticity and uniform shrinkage. Long clay particles, often found in flint or silt inclusions, cause slower firing responses and increase the risk of warping or cracking because they create uneven shrinkage and reduced particle packing. Understanding the particle morphology is crucial for optimizing firing temperature and minimizing defects in ceramic production.

Choosing Between Short Clay and Long Clay for Projects

Short clay particles, typically under 0.002 mm, provide higher plasticity and better water retention, making them ideal for fine, detailed pottery and molding. Long clay particles, with a greater aspect ratio, offer improved structural strength and drying stability, suitable for larger construction projects like bricks and tiles. Selecting the right clay depends on the project's specific requirements for plasticity, strength, and drying time.

Mixing and Modifying Clay Bodies: Tips for Short and Long Clay

Short clay particles create a smooth, plastic texture ideal for hand-building techniques, while long clay particles contribute to greater strength and workability in throwing clay bodies. When mixing, incorporating short clay improves plasticity and reduces cracking, whereas long clay enhances shrinkage control and firing durability. Modifying clay bodies requires balancing the proportion of short and long clays to optimize workability, drying behavior, and final strength.

Storage and Handling Best Practices for Both Clays

Short clay, characterized by its coarse texture and lower plasticity, demands storage in airtight containers to prevent moisture loss and contamination, while handling requires minimal kneading to maintain its workability. Long clay, known for its fine particles and higher plasticity, benefits from slightly more frequent moistening and careful wrapping to avoid drying and cracking during storage. Both clay types should be stored in cool, stable environments, with tools and surfaces kept clean to preserve texture and prevent impurities during handling.

Short Clay vs Long Clay Infographic

materialdif.com

materialdif.com