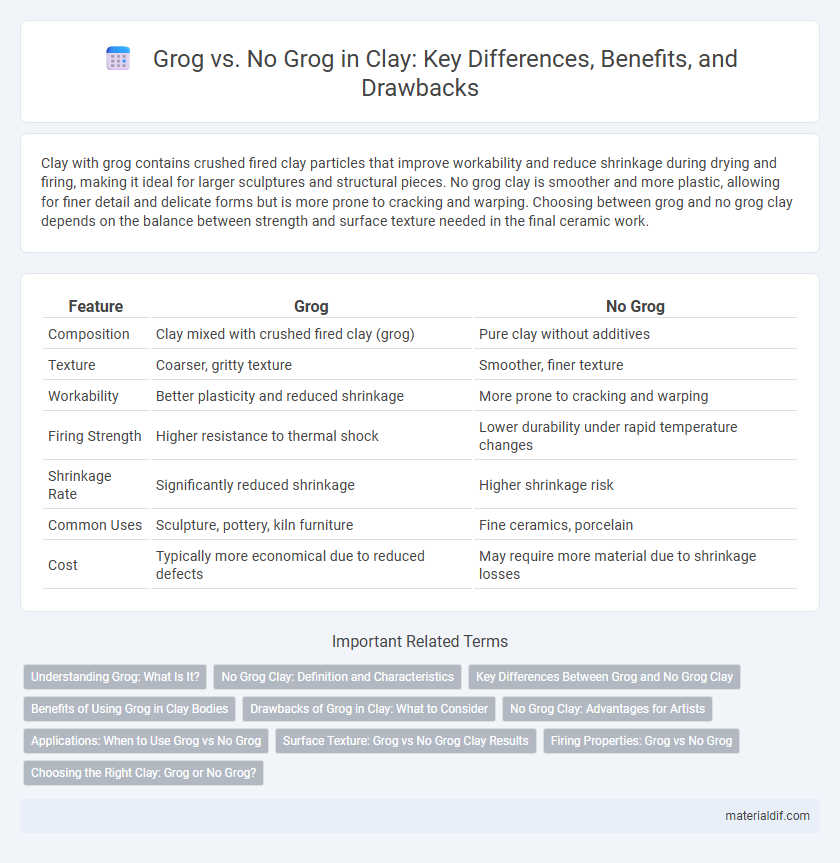

Clay with grog contains crushed fired clay particles that improve workability and reduce shrinkage during drying and firing, making it ideal for larger sculptures and structural pieces. No grog clay is smoother and more plastic, allowing for finer detail and delicate forms but is more prone to cracking and warping. Choosing between grog and no grog clay depends on the balance between strength and surface texture needed in the final ceramic work.

Table of Comparison

| Feature | Grog | No Grog |

|---|---|---|

| Composition | Clay mixed with crushed fired clay (grog) | Pure clay without additives |

| Texture | Coarser, gritty texture | Smoother, finer texture |

| Workability | Better plasticity and reduced shrinkage | More prone to cracking and warping |

| Firing Strength | Higher resistance to thermal shock | Lower durability under rapid temperature changes |

| Shrinkage Rate | Significantly reduced shrinkage | Higher shrinkage risk |

| Common Uses | Sculpture, pottery, kiln furniture | Fine ceramics, porcelain |

| Cost | Typically more economical due to reduced defects | May require more material due to shrinkage losses |

Understanding Grog: What Is It?

Grog is a granular material added to clay to improve its structural properties by reducing shrinkage and enhancing thermal resistance during firing. It consists of pre-fired, crushed clay particles that create a textured consistency, making it ideal for sculpting and wheel-throwing. Understanding grog's composition and function helps potters control the clay body's plasticity, durability, and drying behavior.

No Grog Clay: Definition and Characteristics

No grog clay is a type of ceramic clay that contains no pre-fired clay particles, resulting in a smoother texture and finer surface finish. This clay exhibits high plasticity, making it ideal for detailed sculpting, mold work, and wheel throwing due to its consistent shrinkage and reduced risk of cracking. Its purity allows for enhanced color absorption and a more uniform firing process, making it popular in artistic and functional pottery.

Key Differences Between Grog and No Grog Clay

Grog clay contains pre-fired ceramic particles that improve thermal shock resistance and reduce shrinkage during firing, providing better structural stability for larger or more complex ceramics. No grog clay is smoother and more plastic, allowing finer detail and easier shaping but is more prone to cracking and warping as it dries and fires. The presence of grog significantly impacts workability, drying time, and final strength, making each type suitable for different pottery techniques and end uses.

Benefits of Using Grog in Clay Bodies

Grog enhances clay bodies by increasing thermal shock resistance, reducing shrinkage during drying and firing, and improving strength and workability. It promotes better drying properties, minimizing the risk of cracking and warping in ceramic pieces. Incorporating grog results in more durable, stable pottery suited for both functional wares and sculptural art.

Drawbacks of Grog in Clay: What to Consider

Grog in clay introduces coarse particles that can weaken the overall strength and plasticity, making the material more prone to cracking during drying and firing. The inclusion of grog may cause uneven shrinkage and reduce the clay's workability, posing challenges for fine detail work. Potters should assess the grog's particle size and quantity to balance improved thermal shock resistance against potential structural weaknesses.

No Grog Clay: Advantages for Artists

No grog clay offers smoother texture and greater plasticity, enabling artists to achieve finer details and more delicate forms in their work. Its absence of grog particles reduces abrasion, making it easier to manipulate and allowing for cleaner surfaces in finished pieces. This type of clay is ideal for hand-building and wheel-throwing when precision and smooth finishes are prioritized.

Applications: When to Use Grog vs No Grog

Grog, composed of crushed fired clay, is ideal for applications requiring enhanced thermal shock resistance and reduced shrinkage in pottery and ceramics. Use grog in large-scale sculptures or functional ware like kiln furniture and heat-resistant vessels to increase structural strength and prevent cracking. No grog clay suits fine-detail work, thin-walled pottery, and smooth surface finishes where high plasticity and minimal texture are essential.

Surface Texture: Grog vs No Grog Clay Results

Grog in clay enhances surface texture by adding a gritty, coarse element that improves overall durability and reduces shrinkage during firing. Clay without grog produces a smoother, more plastic surface but is prone to warping and cracking due to higher shrinkage rates. Artists choose grog content based on the desired tactile finish and structural stability of their ceramic pieces.

Firing Properties: Grog vs No Grog

Grog is a granular material added to clay to reduce shrinkage and improve thermal shock resistance during firing. Clay bodies with grog exhibit increased dimensional stability and reduced warping compared to those without grog, making them ideal for high-temperature firings. In contrast, no-grog clays tend to have higher shrinkage and are more susceptible to cracking and deformation during the firing process.

Choosing the Right Clay: Grog or No Grog?

Choosing the right clay involves deciding between grog and no grog based on project needs; grog clay, containing pre-fired clay particles, enhances strength, reduces shrinkage, and improves thermal shock resistance. No grog clay offers a smoother texture ideal for detailed work and sculpting but may be more prone to cracking during firing. Selecting grog clay benefits functional pottery and large-scale pieces, while no grog suits fine art ceramics prioritizing surface finish.

Grog vs No Grog Infographic

materialdif.com

materialdif.com