Terracotta is a porous clay material fired at lower temperatures, making it ideal for decorative pottery and plant pots due to its rustic appearance and breathability. Fireclay, however, is a denser, refractory clay fired at higher temperatures, resulting in superior durability and resistance to heat, commonly used in industrial applications and cookware. The key difference lies in their firing process and resulting strength, with terracotta offering aesthetic warmth and fireclay providing structural resilience.

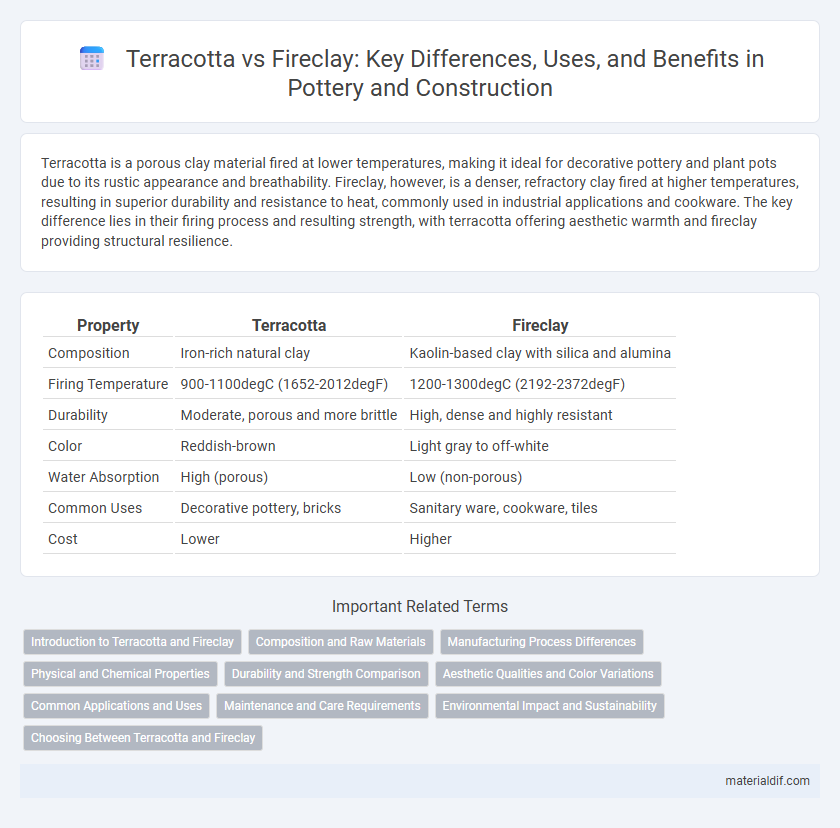

Table of Comparison

| Property | Terracotta | Fireclay |

|---|---|---|

| Composition | Iron-rich natural clay | Kaolin-based clay with silica and alumina |

| Firing Temperature | 900-1100degC (1652-2012degF) | 1200-1300degC (2192-2372degF) |

| Durability | Moderate, porous and more brittle | High, dense and highly resistant |

| Color | Reddish-brown | Light gray to off-white |

| Water Absorption | High (porous) | Low (non-porous) |

| Common Uses | Decorative pottery, bricks | Sanitary ware, cookware, tiles |

| Cost | Lower | Higher |

Introduction to Terracotta and Fireclay

Terracotta, a porous, reddish clay fired at low temperatures, is traditionally used for pottery, tiles, and sculptures, prized for its warm, earthy aesthetic and affordability. Fireclay is a dense, highly refractory clay that withstands extreme heat, commonly utilized for firebricks, furnace linings, and industrial ceramics due to its durability and heat resistance. Both materials originate from natural clay deposits but differ significantly in firing temperatures, composition, and applications based on thermal and structural properties.

Composition and Raw Materials

Terracotta primarily consists of natural clay mixed with iron oxide, giving it its characteristic reddish hue, and contains a moderate amount of silica and alumina. Fireclay, derived from refractory clays, has a higher concentration of alumina and silica, enabling it to withstand extremely high temperatures without deforming. The distinct raw materials and composition differences make terracotta ideal for decorative pottery, while fireclay is preferred for heat-resistant applications like kiln linings and firebricks.

Manufacturing Process Differences

Terracotta is made from a porous, iron-rich clay that is shaped and fired at lower temperatures, typically between 1,000degC and 1,150degC, resulting in a softer, more porous material. Fireclay undergoes a higher firing process at temperatures ranging from 1,200degC to 1,400degC, which vitrifies the clay, producing a denser, more durable, and heat-resistant product. These manufacturing differences impact the material's suitability, with terracotta ideal for decorative and indoor uses, while fireclay is favored for cookware and industrial applications.

Physical and Chemical Properties

Terracotta is a porous, low-fired clay with a characteristic reddish color due to its high iron oxide content, making it less dense and more absorbent than fireclay. Fireclay is composed primarily of kaolin and alumina, fired at higher temperatures, resulting in a dense, non-porous material with superior thermal resistance and chemical inertness. The physical hardness and lower permeability of fireclay make it suitable for heat-resistant applications, while terracotta's porosity limits its structural strength but enhances breathability.

Durability and Strength Comparison

Terracotta, a porous clay material fired at lower temperatures, exhibits moderate durability and strength, making it suitable for decorative applications but less ideal for heavy-use environments. Fireclay undergoes firing at much higher temperatures, resulting in a denser, harder, and more durable product that withstands intense heat and mechanical stress effectively. Comparing both, fireclay outperforms terracotta in structural integrity and longevity, especially in demanding conditions like industrial or kitchen settings.

Aesthetic Qualities and Color Variations

Terracotta exhibits warm, earthy tones ranging from deep reds to soft oranges, creating a rustic and natural aesthetic ideal for artisanal pottery and architectural elements. Fireclay, in contrast, offers a more muted palette with shades of gray, beige, and off-white, lending itself to sleek, modern designs requiring subtle sophistication. Both materials provide distinct color variations that influence the visual impact and textural depth of ceramic works.

Common Applications and Uses

Terracotta is commonly used for decorative pottery, roof tiles, and garden planters due to its porous nature and warm, earthy tones. Fireclay, known for its high heat resistance and durability, is primarily used in industrial applications like kiln linings, fire bricks, and heat-resistant tiles. Both materials serve distinct purposes, with terracotta favored for aesthetic and outdoor uses, while fireclay excels in high-temperature environments.

Maintenance and Care Requirements

Terracotta requires regular sealing and careful handling to prevent cracks and stains due to its porous nature, making maintenance more frequent and intensive. Fireclay, being denser and less porous, demands less sealing and is more resistant to chipping and staining, resulting in easier long-term care. Both materials benefit from gentle cleaning with non-abrasive tools and avoiding harsh chemicals to preserve their durability and appearance.

Environmental Impact and Sustainability

Terracotta is made from natural clay fired at lower temperatures, resulting in lower energy consumption and a smaller carbon footprint compared to fireclay, which requires higher firing temperatures and thus more energy. Terracotta's porosity allows for better biodegradability and less intensive manufacturing processes, enhancing its sustainability credentials. While both materials are durable, terracotta's eco-friendly production and natural composition make it a more sustainable choice in environmentally conscious construction and design.

Choosing Between Terracotta and Fireclay

Choosing between terracotta and fireclay depends on the intended use and durability required. Terracotta is porous and ideal for decorative pottery and gardenware, while fireclay is dense, heat-resistant, and better suited for cookware, sinks, and high-temperature applications. Fireclay's vitrification process makes it stronger and less absorbent than terracotta, enhancing longevity in functional settings.

Terracotta vs Fireclay Infographic

materialdif.com

materialdif.com