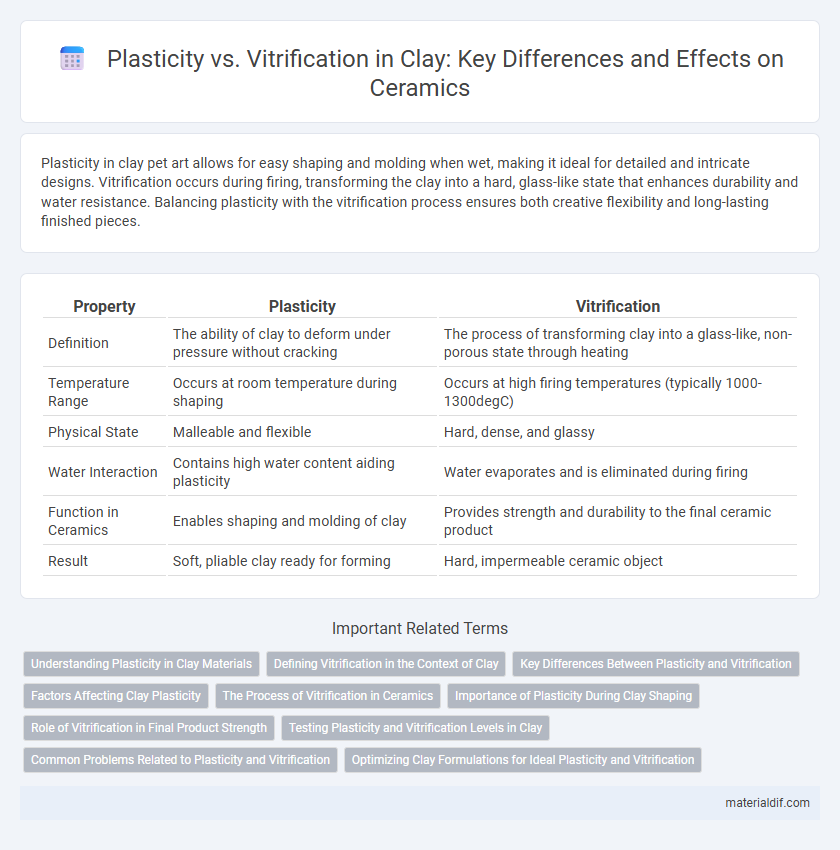

Plasticity in clay pet art allows for easy shaping and molding when wet, making it ideal for detailed and intricate designs. Vitrification occurs during firing, transforming the clay into a hard, glass-like state that enhances durability and water resistance. Balancing plasticity with the vitrification process ensures both creative flexibility and long-lasting finished pieces.

Table of Comparison

| Property | Plasticity | Vitrification |

|---|---|---|

| Definition | The ability of clay to deform under pressure without cracking | The process of transforming clay into a glass-like, non-porous state through heating |

| Temperature Range | Occurs at room temperature during shaping | Occurs at high firing temperatures (typically 1000-1300degC) |

| Physical State | Malleable and flexible | Hard, dense, and glassy |

| Water Interaction | Contains high water content aiding plasticity | Water evaporates and is eliminated during firing |

| Function in Ceramics | Enables shaping and molding of clay | Provides strength and durability to the final ceramic product |

| Result | Soft, pliable clay ready for forming | Hard, impermeable ceramic object |

Understanding Plasticity in Clay Materials

Plasticity in clay materials refers to their ability to be molded and shaped without cracking, which is essential for forming processes in ceramics and construction. This property arises from the presence of water in the clay's microstructure, allowing clay particles to slide past each other while maintaining cohesion. Understanding plasticity helps optimize clay formulation for different applications, balancing workability and structural integrity before vitrification occurs during firing.

Defining Vitrification in the Context of Clay

Vitrification in clay refers to the process where clay particles undergo melting and fusion at high temperatures, resulting in a glass-like, non-porous structure that significantly increases strength and durability. Unlike plasticity, which describes clay's malleable, deformable state when wet, vitrification marks the transition to a rigid, sealed form achieved during firing in a kiln. This transformation is critical for ceramics, as it determines the final product's water resistance and mechanical stability.

Key Differences Between Plasticity and Vitrification

Plasticity in clay refers to its ability to be molded and retain shape when wet, primarily influenced by water content and particle size. Vitrification is the process where clay becomes glass-like and non-porous upon firing at high temperatures, resulting in increased hardness and strength. Key differences include plasticity being a reversible physical state dependent on moisture, while vitrification is an irreversible chemical transformation occurring during kiln firing.

Factors Affecting Clay Plasticity

Clay plasticity depends on mineral composition, particle size, and water content, with montmorillonite exhibiting higher plasticity than kaolinite due to its expansive lattice structure. Organic matter and temperature also influence plasticity by altering the clay's moisture retention and particle bonding capacity. Factors such as drying rate and the presence of salts further modify the transition from plasticity to vitrification during the firing process.

The Process of Vitrification in Ceramics

Vitrification in ceramics occurs when clay particles fuse at high temperatures, transforming the porous material into a dense, glass-like structure. This process reduces plasticity by eliminating moisture and organic components, resulting in increased hardness and water resistance. The degree of vitrification depends on firing temperature and duration, directly influencing the final ceramic strength and durability.

Importance of Plasticity During Clay Shaping

Plasticity in clay is crucial for shaping because it allows the material to be easily molded and retain its form without cracking or collapsing. This property results from the clay particles' ability to slide past each other when wet, enabling smooth manipulation. Unlike vitrification, which occurs during firing and transforms clay into a hardened, glass-like state, plasticity is essential for the initial crafting and detailed sculpting of clay objects.

Role of Vitrification in Final Product Strength

Vitrification transforms clay minerals into a glassy, non-porous phase during firing, significantly increasing the final product's strength and durability. This process reduces porosity, enhancing resistance to water absorption and mechanical stress. Unlike plasticity, which influences shaping, vitrification is crucial for achieving structural integrity in ceramic products.

Testing Plasticity and Vitrification Levels in Clay

Testing plasticity in clay involves measuring its Rejected Plasticity Index (PI) through Atterberg Limits, which determine the moisture range where the clay remains moldable. Vitrification levels are assessed by heating clay samples to observe the temperature at which the material transitions from a porous state to a glass-like, non-porous phase, indicating ceramic maturity. Combining these tests provides essential data on the clay's behavior for applications in pottery, construction, and ceramics manufacturing.

Common Problems Related to Plasticity and Vitrification

Common problems related to clay plasticity include excessive shrinkage, cracking, and warping during drying and firing due to improper moisture content balance. Vitrification issues often arise from insufficient firing temperature or uneven kiln conditions, leading to incomplete fusion and porous, weak ceramic bodies. Managing particle size distribution and controlling firing schedules are essential to overcome defects in both plasticity and vitrification processes.

Optimizing Clay Formulations for Ideal Plasticity and Vitrification

Optimizing clay formulations balances plasticity and vitrification by adjusting particle size distribution, mineral composition, and water content to achieve maximum workability and structural integrity after firing. High plasticity clays contain abundant montmorillonite, allowing easy shaping, while controlled vitrification requires silica and fluxes to form a dense, glassy matrix at lower temperatures. Tailoring the proportions of kaolinite, illite, and flux agents ensures clay bodies maintain plasticity during forming and vitrify effectively to enhance strength and water resistance.

Plasticity vs Vitrification Infographic

materialdif.com

materialdif.com