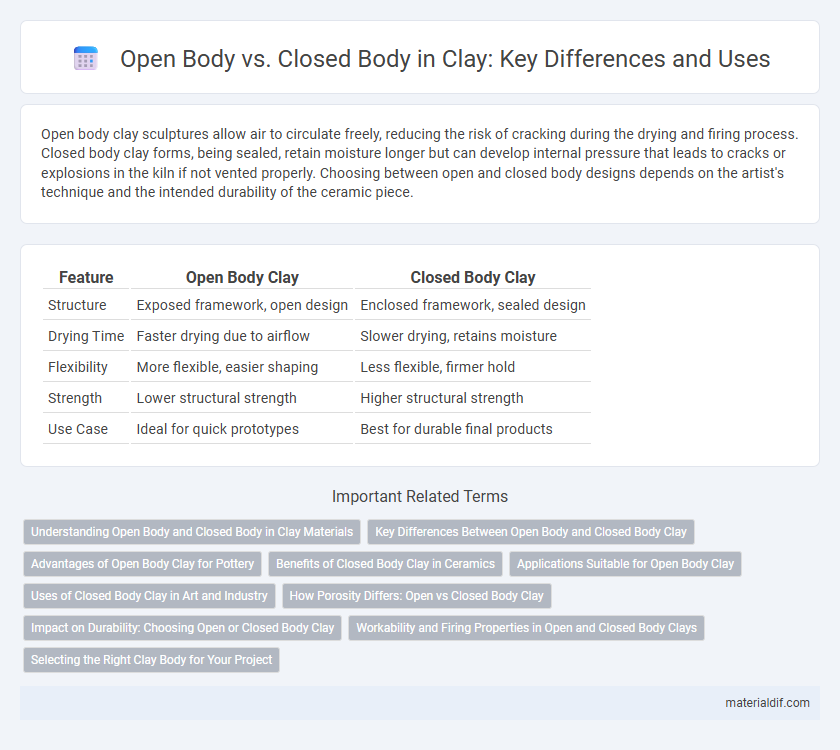

Open body clay sculptures allow air to circulate freely, reducing the risk of cracking during the drying and firing process. Closed body clay forms, being sealed, retain moisture longer but can develop internal pressure that leads to cracks or explosions in the kiln if not vented properly. Choosing between open and closed body designs depends on the artist's technique and the intended durability of the ceramic piece.

Table of Comparison

| Feature | Open Body Clay | Closed Body Clay |

|---|---|---|

| Structure | Exposed framework, open design | Enclosed framework, sealed design |

| Drying Time | Faster drying due to airflow | Slower drying, retains moisture |

| Flexibility | More flexible, easier shaping | Less flexible, firmer hold |

| Strength | Lower structural strength | Higher structural strength |

| Use Case | Ideal for quick prototypes | Best for durable final products |

Understanding Open Body and Closed Body in Clay Materials

Open body clay contains higher porosity and increased iron content, resulting in a more porous, less dense ceramic body that fires at lower temperatures, ideal for rustic, textured finishes. Closed body clay features lower porosity with tightly packed particles and reduced iron content, producing a denser, more vitrified final product that is stronger and less absorbent, suitable for functional ware and fine ceramics. Understanding the differences between open and closed bodies helps potters select the right clay for durability, firing temperature, and desired aesthetics in their ceramic projects.

Key Differences Between Open Body and Closed Body Clay

Open body clay contains higher porosity, allowing air and moisture to escape during firing, which reduces the risk of cracking and creates a more rustic texture. Closed body clay is denser with fewer air pockets, resulting in a stronger, more vitrified final product with a smoother surface, ideal for functional pottery. Key differences include porosity levels, firing behavior, and the resulting texture and strength of the ceramic pieces.

Advantages of Open Body Clay for Pottery

Open body clay offers superior workability and ease of shaping due to its more porous and less dense structure, allowing moisture to evaporate efficiently during the drying process. This type of clay reduces the risk of cracking and warping, making it ideal for intricate pottery designs and thin-walled vessels. Artists benefit from faster drying times and improved firing outcomes, as open body clay promotes even heat distribution in the kiln.

Benefits of Closed Body Clay in Ceramics

Closed body clay in ceramics offers superior durability and reduced porosity compared to open body clays, resulting in stronger, more water-resistant pottery. Its fine particle structure minimizes shrinkage and cracking during drying and firing, ensuring a more stable and uniform final product. This type of clay is ideal for functional ware that requires resilience and longevity, such as dinnerware and storage vessels.

Applications Suitable for Open Body Clay

Open body clay is ideal for sculptors and artists requiring flexibility and ease of manipulation, as its porous texture allows for seamless layering and texturing. This type of clay excels in hand-building techniques, such as coiling and slab construction, where moisture control and breathability enhance workability. Suitable for creating detailed, organic forms, open body clay also performs well in applications involving surface treatments and glazes that benefit from its absorbent properties.

Uses of Closed Body Clay in Art and Industry

Closed body clay, characterized by its low porosity and high density, is widely used in art for creating durable ceramics with smooth finishes and intricate detailing. In industry, its robust properties make it ideal for manufacturing refractory bricks, sanitaryware, and electrical insulators that require resistance to heat and mechanical stress. This type of clay enhances product longevity and performance in applications demanding structural integrity and surface quality.

How Porosity Differs: Open vs Closed Body Clay

Open body clay exhibits higher porosity due to its porous microstructure that allows water and air to pass through easily, making it more absorbent and less vitrified. Closed body clay, in contrast, has a denser, less porous structure where particles fuse more tightly during firing, resulting in lower water absorption and increased strength and durability. Porosity differences between open and closed body clays significantly impact their suitability for functional ceramics versus decorative or structural applications.

Impact on Durability: Choosing Open or Closed Body Clay

Open body clay, characterized by its porous structure, tends to be less durable due to higher water absorption, leading to increased vulnerability to cracking and wear over time. Closed body clay features a denser, non-porous composition, enhancing its resistance to moisture, making it more suitable for functional pottery exposed to frequent use or outdoor conditions. Selecting closed body clay significantly improves the longevity of ceramic pieces by minimizing structural weaknesses caused by environmental factors.

Workability and Firing Properties in Open and Closed Body Clays

Open body clays exhibit high porosity and absorb water readily, enhancing workability by remaining soft and pliable during shaping. Closed body clays possess low porosity, limiting water absorption and requiring more water to achieve plasticity, which can impact the ease of manipulation. During firing, open body clays allow for better gas release, reducing the risk of cracking, while closed body clays often vitrify more uniformly but may trap gases, increasing the potential for defects.

Selecting the Right Clay Body for Your Project

Selecting the right clay body depends on your project's requirements such as firing temperature, workability, and final texture. Open bodies, like earthenware, are porous and ideal for decorative pieces, while closed bodies, such as stoneware and porcelain, vitrify during firing, providing increased strength and water resistance. Understanding the clay's absorption rate, shrinkage, and compatibility with glazes ensures a successful outcome tailored to durability and aesthetic goals.

Open Body vs Closed Body Infographic

materialdif.com

materialdif.com