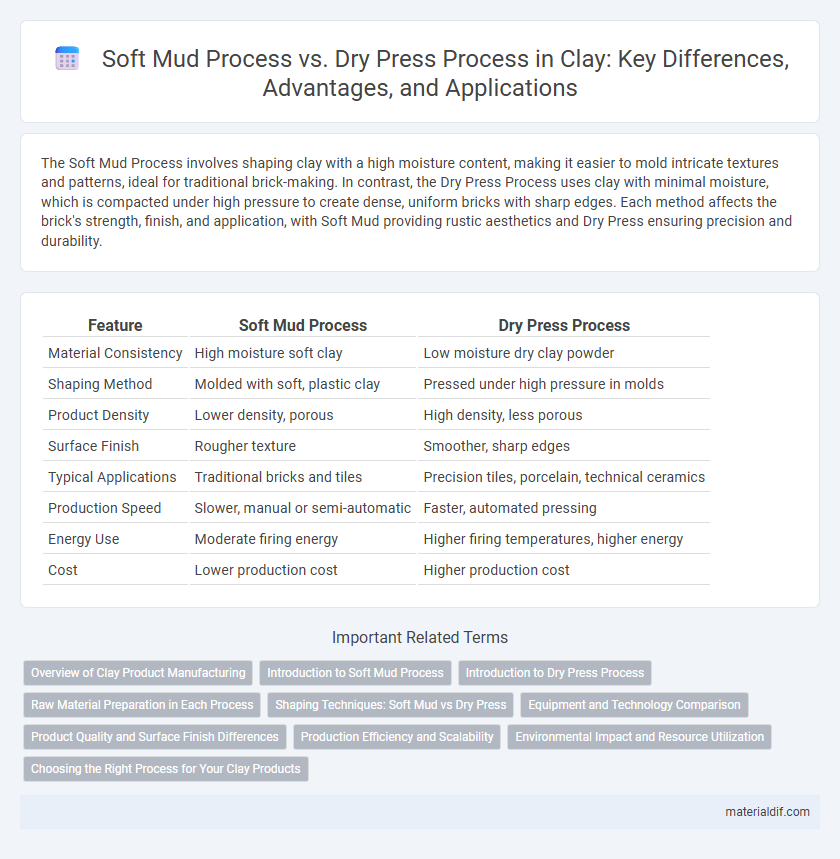

The Soft Mud Process involves shaping clay with a high moisture content, making it easier to mold intricate textures and patterns, ideal for traditional brick-making. In contrast, the Dry Press Process uses clay with minimal moisture, which is compacted under high pressure to create dense, uniform bricks with sharp edges. Each method affects the brick's strength, finish, and application, with Soft Mud providing rustic aesthetics and Dry Press ensuring precision and durability.

Table of Comparison

| Feature | Soft Mud Process | Dry Press Process |

|---|---|---|

| Material Consistency | High moisture soft clay | Low moisture dry clay powder |

| Shaping Method | Molded with soft, plastic clay | Pressed under high pressure in molds |

| Product Density | Lower density, porous | High density, less porous |

| Surface Finish | Rougher texture | Smoother, sharp edges |

| Typical Applications | Traditional bricks and tiles | Precision tiles, porcelain, technical ceramics |

| Production Speed | Slower, manual or semi-automatic | Faster, automated pressing |

| Energy Use | Moderate firing energy | Higher firing temperatures, higher energy |

| Cost | Lower production cost | Higher production cost |

Overview of Clay Product Manufacturing

The Soft Mud Process involves molding clay with high moisture content, allowing for easy shaping and detailed textures in bricks and tiles. The Dry Press Process uses low moisture clay, pressed under high pressure to form dense, uniform products with minimal shrinkage. Both methods influence the final product's strength, porosity, and surface finish, essential factors in selecting clay manufacturing techniques.

Introduction to Soft Mud Process

The Soft Mud Process involves shaping clay with high moisture content, typically between 20-30%, creating a plastic and pliable material ideal for molding into bricks or tiles. This process enhances the workability of clay by integrating water, allowing uniform compaction and detailed shaping before drying and firing. It contrasts with the Dry Press Process, which uses low moisture clay and mechanical pressure to form dense, precise ceramic products.

Introduction to Dry Press Process

The Dry Press Process compacts clay powders into dense, uniform shapes using high pressure, resulting in stronger and more precise ceramic products compared to the Soft Mud Process. This technique reduces moisture content significantly before pressing, enhancing mechanical strength and dimensional accuracy. Primarily used in manufacturing porcelain and fine china, the Dry Press Process supports high-volume production with consistent quality.

Raw Material Preparation in Each Process

The Soft Mud Process uses highly plastic clay mixed with a controlled amount of water to create a malleable mass, enabling easy shaping and molding. In contrast, the Dry Press Process relies on low-plasticity clay with minimal moisture content, which is finely ground and compacted under high pressure. Raw material preparation in the Soft Mud Process emphasizes moisture control for optimal plasticity, while the Dry Press Process focuses on precise grinding and uniform particle size to ensure strong compacted bricks.

Shaping Techniques: Soft Mud vs Dry Press

The Soft Mud process involves shaping clay with high moisture content using molds or hand shaping, resulting in a more porous and textured surface ideal for decorative ceramics. In contrast, the Dry Press process compresses nearly dry clay powders under high pressure into rigid molds, producing denser, more uniform, and stronger ware suitable for structural applications. Soft Mud shaping allows greater flexibility and organic forms, while Dry Press excels in precision and consistency for mass production.

Equipment and Technology Comparison

The Soft Mud Process employs wooden molds and pugging machines to shape malleable clay, relying on humidity control and manual or semi-automated molding equipment, which allows for intricate detailing but slower production rates. In contrast, the Dry Press Process utilizes hydraulic presses and finely ground clay powders, enabling high-pressure compaction and automation that produces uniform, dense bricks with minimal moisture content, improving strength and reducing drying time. Technological advancements in dry pressing include computerized control systems and precision pressure application, enhancing efficiency and product quality compared to the traditional soft mud technique.

Product Quality and Surface Finish Differences

The Soft Mud process produces ceramic products with a more plastic and homogeneous body, resulting in a smoother surface finish and greater strength due to better particle bonding during shaping. In contrast, the Dry Press process compacts dry clay powders under high pressure, allowing for higher precision in form and density but often yielding a rougher surface finish that may require additional finishing treatments. Product quality in the Soft Mud process is characterized by fewer internal defects and enhanced durability, whereas the Dry Press process excels in dimensional accuracy and mass production efficiency.

Production Efficiency and Scalability

The Soft Mud Process offers higher production efficiency due to its lower energy consumption and faster drying times compared to the Dry Press Process, making it ideal for large-scale brick manufacturing. In contrast, the Dry Press Process provides superior precision and uniformity, but its slower cycle times limit scalability in high-volume production. Manufacturers seeking to maximize output often prefer the Soft Mud Process for its adaptability to automated systems and continuous operation capabilities.

Environmental Impact and Resource Utilization

The Soft Mud Process uses higher water content, leading to increased energy consumption during drying but enables effective recycling of clay waste, reducing raw material extraction and landfill burden. The Dry Press Process requires less water, minimizing drying energy but often produces higher amounts of off-spec material, resulting in greater resource wastage and environmental strain. Evaluating these methods highlights that Soft Mud Process offers better resource utilization through waste recycling, whereas Dry Press Process reduces water usage but may contribute to increased material waste and emissions.

Choosing the Right Process for Your Clay Products

Choosing the right process for your clay products depends on the desired texture, strength, and production scale. The Soft Mud Process excels in producing porous, textured bricks suitable for aesthetic designs and smaller batches, while the Dry Press Process offers higher density and precision, ideal for structural applications requiring uniformity and durability. Understanding the project's specific requirements ensures optimal performance and cost-efficiency by selecting between these distinct clay forming techniques.

Soft Mud Process vs Dry Press Process Infographic

materialdif.com

materialdif.com