Glazing creates a glass-like, glossy surface on clay that enhances color depth and provides waterproofing, while underglazing involves applying colored decoration beneath a transparent glaze for detailed designs and matte finishes. Underglazes allow precise control of patterns and colors that do not run during firing, making them ideal for intricate artwork. Choosing between glazing and underglazing depends on the desired texture and visual effect of the final ceramic piece.

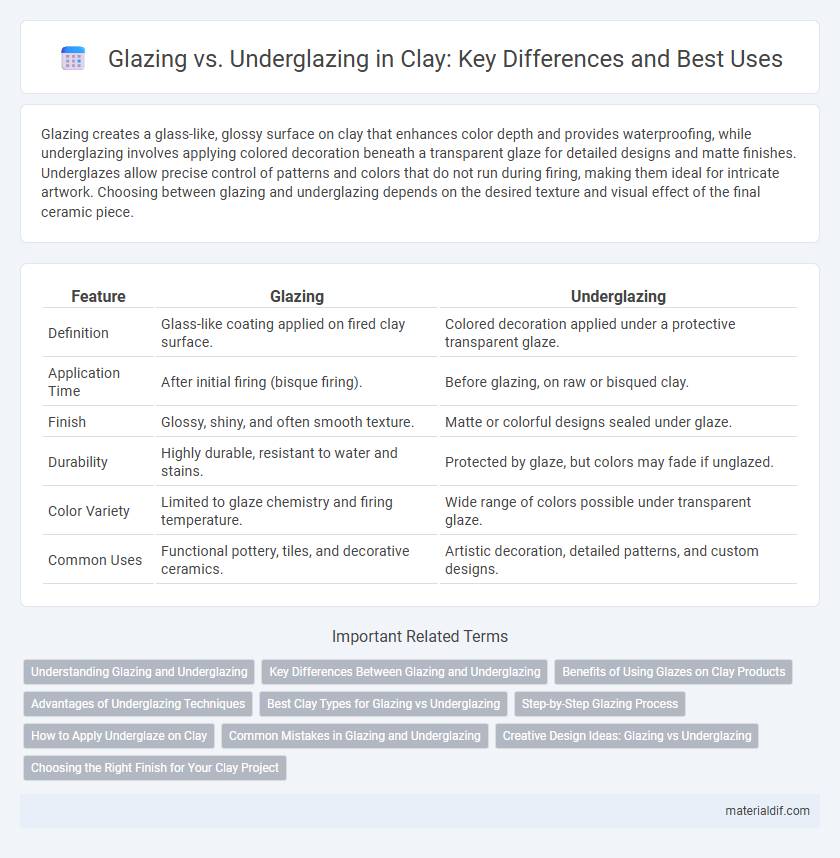

Table of Comparison

| Feature | Glazing | Underglazing |

|---|---|---|

| Definition | Glass-like coating applied on fired clay surface. | Colored decoration applied under a protective transparent glaze. |

| Application Time | After initial firing (bisque firing). | Before glazing, on raw or bisqued clay. |

| Finish | Glossy, shiny, and often smooth texture. | Matte or colorful designs sealed under glaze. |

| Durability | Highly durable, resistant to water and stains. | Protected by glaze, but colors may fade if unglazed. |

| Color Variety | Limited to glaze chemistry and firing temperature. | Wide range of colors possible under transparent glaze. |

| Common Uses | Functional pottery, tiles, and decorative ceramics. | Artistic decoration, detailed patterns, and custom designs. |

Understanding Glazing and Underglazing

Glazing involves applying a glossy or matte glass-like coating that fuses to the clay surface after firing, enhancing durability and color depth, while underglazing uses pigmented slips applied before a clear glaze, allowing detailed designs and stable colors that don't run during firing. Understanding the chemical composition and firing temperatures of both techniques is essential for achieving desired finishes and preventing defects like crazing or peeling. Artists choose glazing for smooth, protective finishes and underglazing for precise, intricate patterns with vibrant, controlled coloration.

Key Differences Between Glazing and Underglazing

Glazing involves applying a glassy coating that becomes smooth and shiny after firing, enhancing both the durability and waterproof qualities of clay pieces, while underglazing uses colored slips applied before glazing to create detailed, vibrant designs without altering the texture. The key difference lies in the finish and application process; glazing provides a glossy, protective surface, whereas underglazing focuses on intricate decoration that remains visible beneath a clear glaze. Understanding these distinctions helps ceramic artists choose the right technique for surface aesthetics and functional properties.

Benefits of Using Glazes on Clay Products

Glazing clay products enhances durability by creating a glass-like surface that resists water, stains, and scratches, making them ideal for functional pottery such as bowls and plates. The glossy finish of glazes also intensifies color vibrancy and adds an aesthetic appeal that underglazing alone cannot achieve. Furthermore, glazes provide a smooth, food-safe surface essential for ceramics used in kitchens and dining.

Advantages of Underglazing Techniques

Underglazing techniques offer precise color application that remains stable during firing, allowing for detailed and intricate designs on clay surfaces. This method provides enhanced durability and resistance to scratching or fading compared to traditional glazing. Artists benefit from greater control over the final appearance, as underglazes maintain their color clarity beneath a transparent glaze.

Best Clay Types for Glazing vs Underglazing

Porcelain and stoneware are the best clay types for glazing due to their dense, vitrified surfaces that enhance glaze adherence and provide durability. Earthenware clay is ideal for underglazing as its porous nature absorbs underglaze colors well, producing vibrant, matte finishes after firing. Ball clay blends work effectively for both techniques by balancing plasticity and porosity, making them versatile for detailed glaze and underglaze applications.

Step-by-Step Glazing Process

The step-by-step glazing process begins with thoroughly cleaning the bisque-fired clay surface to ensure proper glaze adhesion. Next, apply the glaze evenly using brushing, dipping, or spraying techniques, allowing each layer to dry appropriately before adding subsequent coats. Finally, fire the glazed piece in a kiln at the recommended temperature specific to the glaze type, resulting in a smooth, glass-like finish that enhances both durability and visual appeal.

How to Apply Underglaze on Clay

To apply underglaze on clay, start by preparing the bisque-fired surface to ensure proper adhesion. Use a brush, sponge, or dipping method to evenly coat the clay with underglaze, allowing each layer to dry before applying the next for vibrant, layered effects. Seal the underglaze with a clear glaze before the final firing to enhance color durability and surface texture.

Common Mistakes in Glazing and Underglazing

Common mistakes in glazing include applying glaze too thickly, causing drips and uneven surfaces, and firing at incorrect temperatures that lead to poor glaze maturation or surface defects. Underglazing errors often stem from using incompatible clay bodies or underglazes that crack during drying or firing, as well as insufficient layering or blending that results in dull or uneven coloration. Proper technique involves careful control of glaze application thickness, compatibility checking between clay and underglaze materials, and firing according to manufacturer specifications to ensure optimal finish and durability.

Creative Design Ideas: Glazing vs Underglazing

Glazing offers vibrant, glossy surfaces with rich color depth that enhances intricate details, making it ideal for bold creative designs on ceramic pieces. Underglazing allows for precise, fine-line patterns and layering of colors that resist blending during firing, perfect for detailed illustrations and complex motifs. Combining glazing and underglazing techniques enables artists to experiment with texture, transparency, and color contrasts, producing visually dynamic and innovative pottery.

Choosing the Right Finish for Your Clay Project

Choosing the right finish for your clay project depends on the desired aesthetic and functional qualities, with glazing offering a glossy, durable layer that enhances color vibrancy and water resistance. Underglazing provides detailed design control, allowing for intricate patterns and matte finishes that merge seamlessly under a clear glaze. Selecting between glazing and underglazing hinges on project goals such as surface texture, firing temperature compatibility, and intended use.

Glazing vs Underglazing Infographic

materialdif.com

materialdif.com