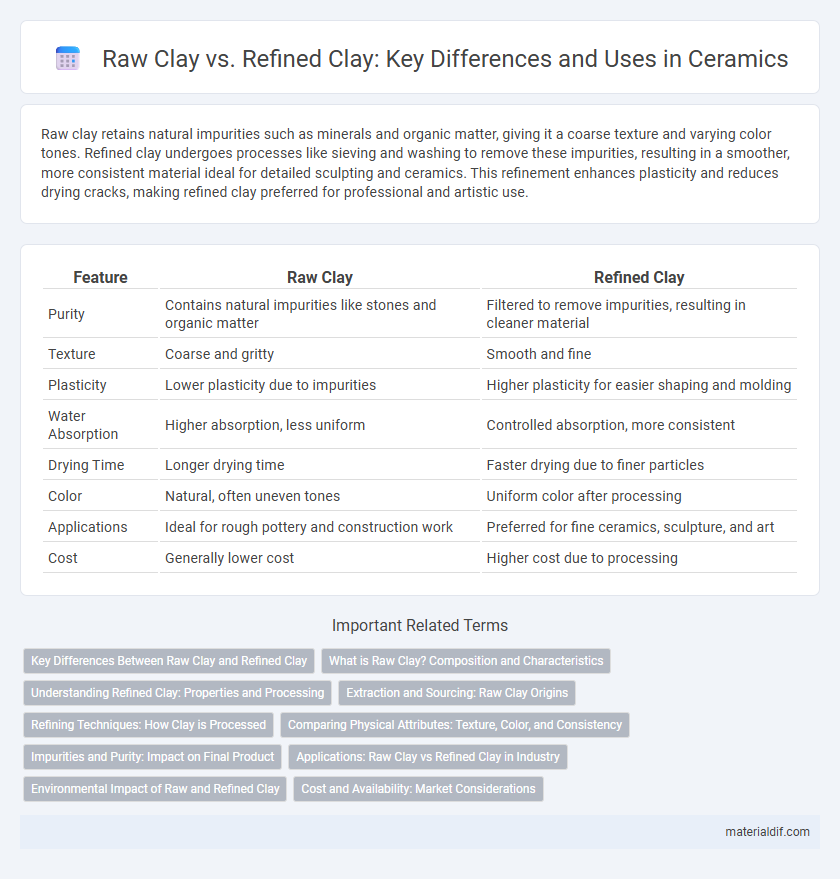

Raw clay retains natural impurities such as minerals and organic matter, giving it a coarse texture and varying color tones. Refined clay undergoes processes like sieving and washing to remove these impurities, resulting in a smoother, more consistent material ideal for detailed sculpting and ceramics. This refinement enhances plasticity and reduces drying cracks, making refined clay preferred for professional and artistic use.

Table of Comparison

| Feature | Raw Clay | Refined Clay |

|---|---|---|

| Purity | Contains natural impurities like stones and organic matter | Filtered to remove impurities, resulting in cleaner material |

| Texture | Coarse and gritty | Smooth and fine |

| Plasticity | Lower plasticity due to impurities | Higher plasticity for easier shaping and molding |

| Water Absorption | Higher absorption, less uniform | Controlled absorption, more consistent |

| Drying Time | Longer drying time | Faster drying due to finer particles |

| Color | Natural, often uneven tones | Uniform color after processing |

| Applications | Ideal for rough pottery and construction work | Preferred for fine ceramics, sculpture, and art |

| Cost | Generally lower cost | Higher cost due to processing |

Key Differences Between Raw Clay and Refined Clay

Raw clay contains natural impurities such as sand, organic matter, and minerals that affect its texture and plasticity, making it heavier and coarser. Refined clay undergoes processes like sieving and washing to remove these impurities, resulting in a smoother, more consistent material ideal for detailed sculpting and pottery. The key differences lie in purity, workability, and drying behavior, with refined clay offering enhanced malleability and reduced cracking during drying and firing.

What is Raw Clay? Composition and Characteristics

Raw clay is a natural material composed primarily of fine-grained minerals such as kaolinite, illite, and montmorillonite, mixed with organic matter and impurities like sand and silt. It exhibits plasticity when wet, allowing it to be molded, and becomes hard and durable upon drying and firing. The chemical composition varies by location but typically includes hydrous aluminum silicates, which contribute to its cohesive properties and workability in ceramics and construction.

Understanding Refined Clay: Properties and Processing

Refined clay undergoes processes such as washing, screening, and grinding to remove impurities and achieve a uniform texture, enhancing its plasticity and workability compared to raw clay. This purification results in improved particle size distribution, higher mineral purity, and consistent moisture content, which are essential for producing high-quality ceramics and pottery. Understanding the physical and chemical properties of refined clay allows manufacturers to tailor formulas for specific applications, ensuring better durability, strength, and aesthetic finish in the final product.

Extraction and Sourcing: Raw Clay Origins

Raw clay originates from natural deposits found in riverbeds, lakes, and soil layers where minerals such as kaolinite, illite, and montmorillonite accumulate through weathering of rocks. Extraction involves minimal processing, typically involving mining or digging to gather the clay directly from the earth, often in locations with rich sedimentary deposits. Sourcing raw clay depends on geological formations and local environmental conditions, influencing its mineral composition and plasticity essential for various ceramic and industrial applications.

Refining Techniques: How Clay is Processed

Raw clay contains impurities such as sand, silt, and organic matter that affect the texture and quality of the final product. Refining techniques like wedging, sieving, and levigation remove these impurities, resulting in a smoother, more plastic clay body suitable for detailed pottery and sculpture. Advanced methods such as centrifugation and flotation further enhance purity by separating fine clay particles from coarser materials.

Comparing Physical Attributes: Texture, Color, and Consistency

Raw clay displays a coarse texture with visible impurities, exhibiting a dull, earthy color and uneven consistency that affects molding precision. Refined clay undergoes processing to remove debris and homogenize particles, resulting in a smooth, fine texture, vibrant color uniformity, and consistent plasticity ideal for detailed sculpting. These physical differences critically impact usability, with refined clay preferred in professional ceramics for its predictable behavior and superior finish quality.

Impurities and Purity: Impact on Final Product

Raw clay contains natural impurities such as sand, silt, and organic matter that affect the texture and strength of the final product, leading to uneven drying and reduced durability. Refined clay undergoes processes like sieving and washing to remove these impurities, resulting in a smoother, more consistent material ideal for high-quality ceramics and pottery. The purity level directly influences the workability and aesthetic finish, making refined clay preferable for precision crafting and professional use.

Applications: Raw Clay vs Refined Clay in Industry

Raw clay, rich in natural minerals and organic matter, is predominantly used in traditional ceramics, pottery, and brick manufacturing due to its plasticity and ease of shaping. Refined clay undergoes processes like screening and washing to remove impurities, making it ideal for high-quality applications such as porcelain production, advanced ceramics, and specialized industrial molds requiring enhanced purity and consistency. Industries prioritize refined clay for products demanding greater mechanical strength, uniformity, and surface finish, while raw clay finds application where cost-effectiveness and natural composition are sufficient.

Environmental Impact of Raw and Refined Clay

Raw clay extraction involves minimal processing, resulting in lower energy consumption and reduced carbon emissions compared to refined clay production. Refined clay requires extensive beneficiation processes, including washing, drying, and grinding, which increase water usage and generate industrial waste that can harm local ecosystems. The environmental footprint of raw clay is generally smaller, making it a more sustainable choice for eco-conscious applications.

Cost and Availability: Market Considerations

Raw clay is generally more affordable and widely available due to minimal processing, making it a cost-effective option for large-scale or budget-conscious projects. Refined clay involves extensive processing to remove impurities, resulting in higher production costs and often limited availability in specialty markets. Market demand for refined clay is driven by applications requiring superior quality and consistency, despite its premium price.

Raw Clay vs Refined Clay Infographic

materialdif.com

materialdif.com