Raku pottery involves rapid firing and cooling, creating unique crackled glazes and smoky effects, while Saggar firing encloses ceramics in a container filled with combustibles to produce varied surface textures and colors. Raku typically emphasizes unpredictability and spontaneity in glaze results, contrasting with the controlled yet experimental atmosphere achieved in Saggar firings. Both techniques highlight the artist's interaction with fire, but Saggar allows for more layered and organic markings on the clay surface.

Table of Comparison

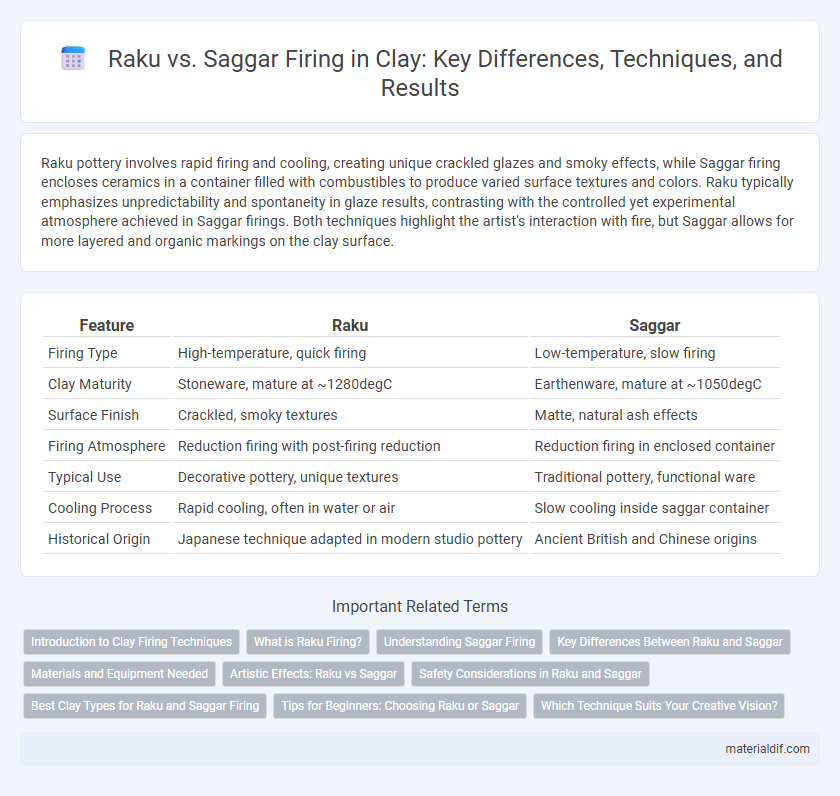

| Feature | Raku | Saggar |

|---|---|---|

| Firing Type | High-temperature, quick firing | Low-temperature, slow firing |

| Clay Maturity | Stoneware, mature at ~1280degC | Earthenware, mature at ~1050degC |

| Surface Finish | Crackled, smoky textures | Matte, natural ash effects |

| Firing Atmosphere | Reduction firing with post-firing reduction | Reduction firing in enclosed container |

| Typical Use | Decorative pottery, unique textures | Traditional pottery, functional ware |

| Cooling Process | Rapid cooling, often in water or air | Slow cooling inside saggar container |

| Historical Origin | Japanese technique adapted in modern studio pottery | Ancient British and Chinese origins |

Introduction to Clay Firing Techniques

Raku firing is a rapid, low-temperature process that involves removing hot pottery from the kiln and cooling it quickly, often with post-firing reduction in combustible materials to create unique surface effects. Saggar firing encloses pottery in a protective container filled with combustible materials, allowing for controlled atmospheres that produce intricate patterns and textures during high-temperature firing. Both techniques emphasize creative experimentation and distinct aesthetic results, making them popular choices for artists exploring innovative clay firing methods.

What is Raku Firing?

Raku firing is a rapid ceramic firing process that involves removing hot pottery from the kiln at peak temperature and placing it into combustible materials like sawdust or leaves, causing a reduction atmosphere that creates unique surface effects and crackles. This technique contrasts with Saggar firing, where clay pieces are enclosed in a protective container to shield them from direct flames and ash, resulting in nuanced textures and colors without the intense thermal shock of Raku. The unpredictable nature of Raku firing makes each piece distinct, prized for its organic, expressive qualities.

Understanding Saggar Firing

Saggar firing involves placing clay pieces inside protective containers, called saggars, to shield them from direct flame and ash during firing, resulting in unique surface textures and color variations. This method contrasts with Raku firing, which exposes ceramics to rapid cooling after removal from the kiln, producing crackled glazes and metallic effects. Understanding saggar firing allows artists to manipulate atmospheric conditions, creating distinct visual effects rooted in historical ceramic traditions.

Key Differences Between Raku and Saggar

Raku firing involves removing pottery from the kiln while hot and allowing rapid cooling, producing crackled glaze effects and smoky textures, whereas Saggar firing encloses pottery in a container filled with combustible materials to create unique surface patterns through controlled smoke and flame interaction. Raku is characterized by its quick firing cycle and unpredictability in glaze outcomes, commonly used for decorative ceramics, while Saggar firing is often applied for more intricate, layered surface effects and can involve longer firing times. The main difference lies in the firing technique and atmosphere control, with Raku emphasizing thermal shock and Saggar focusing on direct contact with volatile materials for surface decoration.

Materials and Equipment Needed

Raku firing requires porous earthenware clay and a gas or electric kiln capable of rapid heating and cooling, along with essential materials like glaze, tongs, and a metal container for post-firing reduction. Saggar firing involves using stoneware or porcelain clay, a saggar box made from refractory materials such as fire clay or alumina, and combustible materials like sawdust, leaves, or salt to create unique surface effects during the firing process. Both techniques demand specific equipment tailored to their firing styles to achieve the desired aesthetic outcomes.

Artistic Effects: Raku vs Saggar

Raku firing produces unpredictable crackles, metallic lusters, and smoky textures, enhancing the organic aesthetic of ceramic pieces. Saggar firing introduces vibrant, multicolored surface patterns through the interaction of combustibles and minerals within the enclosed container. Both techniques create unique, textured finishes, with Raku emphasizing rapid cooling effects and Saggar offering controlled chemical reactions for diverse coloration.

Safety Considerations in Raku and Saggar

Raku firing involves rapid temperature changes and open flame exposure, requiring careful handling to prevent thermal shock and burns, emphasizing the use of heat-resistant gloves and proper ventilation. Saggar firing exposes clay to smoke and combustible materials inside a container, necessitating attention to toxic fumes and fire hazards by ensuring adequate air flow and protective gear. Both techniques demand awareness of high heat risks and appropriate safety measures to protect artists from injury and health hazards.

Best Clay Types for Raku and Saggar Firing

Raku firing benefits from groggy stoneware clay or porcelain due to their thermal shock resistance and ability to withstand rapid cooling. Saggar firing suits buff stoneware clay or earthenware, which absorb ash and fluxing materials well, creating unique surface effects. Both methods require clays with good workability and low shrinkage to prevent cracking during firing.

Tips for Beginners: Choosing Raku or Saggar

Beginners choosing between Raku and Saggar firing should consider Raku for its quick, low-temperature firing process that offers vibrant colors and crackled textures, ideal for experimenting with surface effects. Saggar firing, involving placing pottery in a protective container filled with combustible materials, creates unique smoky patterns and textures but requires more control over kiln atmosphere and timing. Selecting Raku simplifies learning with immediate results, while Saggar demands patience and experience to master complex reductions and firing variations.

Which Technique Suits Your Creative Vision?

Raku firing offers rapid cooling and unpredictable glaze effects, ideal for artists seeking spontaneity and texture in their ceramic pieces. Saggar firing provides controlled atmospheres and layered smoke patterns, perfect for those who prioritize detailed surface decoration and subtle color variations. Choosing between Raku and Saggar hinges on whether your creative vision values dynamic, bold finishes or intricate, nuanced designs.

Raku vs Saggar Infographic

materialdif.com

materialdif.com