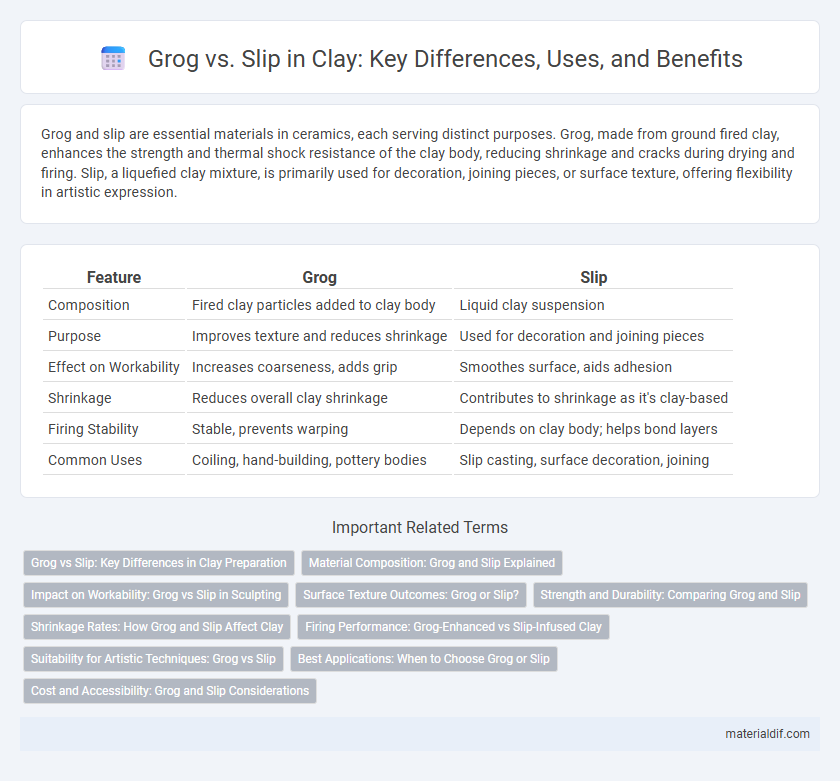

Grog and slip are essential materials in ceramics, each serving distinct purposes. Grog, made from ground fired clay, enhances the strength and thermal shock resistance of the clay body, reducing shrinkage and cracks during drying and firing. Slip, a liquefied clay mixture, is primarily used for decoration, joining pieces, or surface texture, offering flexibility in artistic expression.

Table of Comparison

| Feature | Grog | Slip |

|---|---|---|

| Composition | Fired clay particles added to clay body | Liquid clay suspension |

| Purpose | Improves texture and reduces shrinkage | Used for decoration and joining pieces |

| Effect on Workability | Increases coarseness, adds grip | Smoothes surface, aids adhesion |

| Shrinkage | Reduces overall clay shrinkage | Contributes to shrinkage as it's clay-based |

| Firing Stability | Stable, prevents warping | Depends on clay body; helps bond layers |

| Common Uses | Coiling, hand-building, pottery bodies | Slip casting, surface decoration, joining |

Grog vs Slip: Key Differences in Clay Preparation

Grog consists of crushed fired clay added to raw clay to reduce shrinkage and improve structural strength, while slip is a liquid mixture of clay and water used primarily for joining pieces and surface decoration. Grog enhances clay's texture and drying properties, making it ideal for hand-building and functional pottery, whereas slip facilitates smooth adhesive bonding and can create artistic effects. Understanding the differences between grog and slip is essential for optimizing clay preparation techniques in ceramics.

Material Composition: Grog and Slip Explained

Grog is composed of crushed, fired clay particles mixed into raw clay to improve its thermal shock resistance, reduce shrinkage, and add strength during the firing process. Slip is a liquid mixture of finely ground clay and water, often used as an adhesive or surface decoration rather than to alter the clay body itself. The key difference in material composition lies in grog's coarse, refractory inclusions versus slip's smooth, fluid consistency designed for coating and joining.

Impact on Workability: Grog vs Slip in Sculpting

Grog enhances the workability of clay by improving its texture and reducing shrinkage, making it ideal for hand-building and sculpting detailed forms. Slip, a liquid mixture of clay and water, is primarily used as a bonding agent to join pieces or create surface finishes but can affect the overall consistency and handling of the clay if applied excessively. Choosing between grog and slip depends on the desired structural integrity and surface quality in sculptural projects.

Surface Texture Outcomes: Grog or Slip?

Grog enhances surface texture by adding a gritty, rough feel that increases durability and reduces shrinkage in clay bodies. Slip, a liquid clay mixture, provides a smooth, even coating ideal for surface decoration and bonding but results in a finer, less textured finish. Choosing between grog and slip depends on whether the desired outcome is a coarse, tactile surface or a sleek, polished look in ceramic work.

Strength and Durability: Comparing Grog and Slip

Grog enhances clay's strength and durability by adding fired, ground-up ceramic particles, improving resistance to cracking and shrinkage during drying and firing. Slip, a liquid mixture of clay and water, is primarily used for joining pieces and surface decoration but does not significantly increase the structural integrity of the clay body. The inclusion of grog is essential for creating stronger, more durable ceramics, especially in functional or large-scale pottery.

Shrinkage Rates: How Grog and Slip Affect Clay

Grog reduces shrinkage rates in clay by incorporating pre-fired particles that create internal structure, minimizing cracking during drying and firing. Slip, a liquid clay mixture, typically exhibits higher shrinkage because it lacks the structural reinforcements of grog. Understanding the different shrinkage impacts helps ceramists select appropriate materials for stable, durable ceramic pieces.

Firing Performance: Grog-Enhanced vs Slip-Infused Clay

Grog-enhanced clay exhibits superior firing performance due to its improved thermal shock resistance and reduced shrinkage, enabling pottery to withstand higher temperatures without cracking. Slip-infused clay provides a smoother surface and better plasticity before firing but tends to have higher shrinkage and lower thermal stability compared to grog additives. The presence of grog particles enhances the structural integrity and durability of fired ceramics, making it ideal for high-temperature applications, unlike slip which primarily affects surface finish.

Suitability for Artistic Techniques: Grog vs Slip

Grog, made from fired and crushed clay, offers superior texture and strength, making it ideal for sculpting and hand-building techniques requiring added durability and surface grip. Slip, a liquid clay mixture, excels in decorative applications such as painting, joining pieces, and creating smooth, glossy finishes due to its fluid consistency. Choosing between grog and slip depends on whether the artistic technique prioritizes structural support and texture or fine detail and surface decoration.

Best Applications: When to Choose Grog or Slip

Grog is best used in ceramic projects requiring enhanced thermal shock resistance and structural strength, making it ideal for larger, hand-built pieces and functional pottery. Slip, a liquid clay mixture, excels in decorative applications such as slip casting, surface decoration, and joining pieces before firing. Choosing grog improves durability and reduces cracking during firing, while slip ensures smooth adhesion and detailed aesthetics in ceramic work.

Cost and Accessibility: Grog and Slip Considerations

Grog, made from crushed fired clay, generally costs more due to its additional processing and specialized manufacturing techniques, while slip, a liquid mixture of clay and water, is cheaper and easier to produce. Accessibility to grog can be limited by local suppliers or the need to source specific grog materials, whereas slip is readily available or can be prepared on-site with basic materials. Budget-conscious potters often prefer slip for affordability, but grog's unique textural properties justify its higher expense in certain ceramic projects.

Grog vs Slip Infographic

materialdif.com

materialdif.com