Raku firing involves removing pottery from the kiln while red-hot and rapidly cooling it in combustible materials, creating unique textures and metallic finishes through reduction atmosphere effects. Oxidation firing exposes ceramics to oxygen throughout the firing process, resulting in brighter and more consistent colors without the smoky or crackled surfaces typical of Raku. Choosing between Raku and oxidation firing influences the final appearance and strength of clay pieces, with Raku favoring artistic unpredictability and oxidation emphasizing controlled, even glazing.

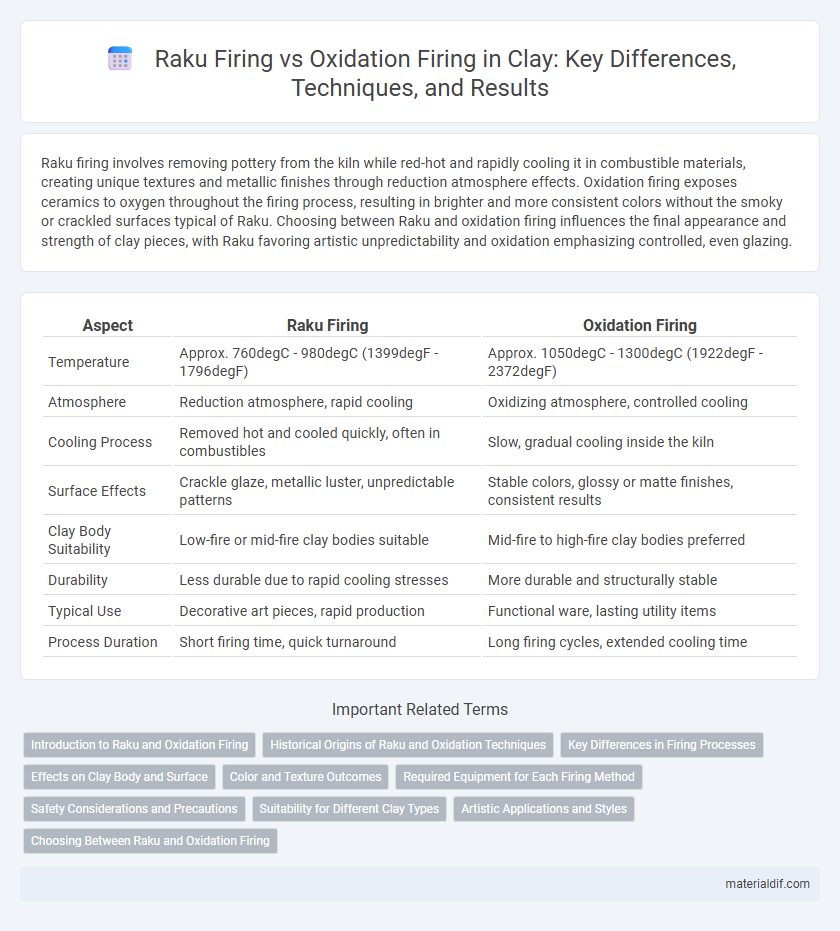

Table of Comparison

| Aspect | Raku Firing | Oxidation Firing |

|---|---|---|

| Temperature | Approx. 760degC - 980degC (1399degF - 1796degF) | Approx. 1050degC - 1300degC (1922degF - 2372degF) |

| Atmosphere | Reduction atmosphere, rapid cooling | Oxidizing atmosphere, controlled cooling |

| Cooling Process | Removed hot and cooled quickly, often in combustibles | Slow, gradual cooling inside the kiln |

| Surface Effects | Crackle glaze, metallic luster, unpredictable patterns | Stable colors, glossy or matte finishes, consistent results |

| Clay Body Suitability | Low-fire or mid-fire clay bodies suitable | Mid-fire to high-fire clay bodies preferred |

| Durability | Less durable due to rapid cooling stresses | More durable and structurally stable |

| Typical Use | Decorative art pieces, rapid production | Functional ware, lasting utility items |

| Process Duration | Short firing time, quick turnaround | Long firing cycles, extended cooling time |

Introduction to Raku and Oxidation Firing

Raku firing is a rapid, low-temperature ceramic firing technique known for producing unique, unpredictable surface effects by removing pieces from the kiln while glowing hot and cooling them quickly in combustible materials. Oxidation firing involves burning ceramics in an environment with abundant oxygen, resulting in brighter, more consistent colors and stronger clay bodies. Understanding the distinct atmospheric conditions of Raku and oxidation firing is essential for artists aiming to manipulate glaze results and surface textures effectively.

Historical Origins of Raku and Oxidation Techniques

Raku firing originated in 16th-century Japan, where it was developed by tea master Sen no Rikyu as a rapid, low-temperature firing technique for tea bowls, emphasizing spontaneity and natural results. Oxidation firing, on the other hand, has roots in ancient pottery traditions across various cultures, relying on controlled oxygen supply in the kiln to produce consistent, bright, and stable clay surfaces. The distinct historical origins highlight Raku's artistic unpredictability contrasted with the precision and durability valued in oxidation firing methods.

Key Differences in Firing Processes

Raku firing involves rapid heating and cooling cycles, producing unique thermal shocks that create crackled textures and unpredictable glaze effects unlike the steady, controlled atmosphere in oxidation firing. Oxidation firing maintains a consistent supply of oxygen throughout the kiln, allowing for uniform color development and smoother finishes on ceramic pieces. The key difference lies in raku's open-air removal at peak temperature versus oxidation's closed kiln environment favoring durability and color stability in the final clay work.

Effects on Clay Body and Surface

Raku firing induces rapid temperature shifts causing thermal shock effects that create unique crackles and surface textures in the clay body, often resulting in porous, lightweight pieces with smoky, unpredictable finishes. Oxidation firing maintains a consistent oxygen-rich environment, preserving the clay body's inherent color and enhancing glaze vibrancy with smooth, stable surfaces and reduced risk of cracking. The chemical reactions in raku firing alter the clay's microstructure, whereas oxidation firing promotes uniform vitrification, affecting durability and aesthetic qualities distinctly.

Color and Texture Outcomes

Raku firing produces unpredictable and vibrant colors with crackled textures due to rapid cooling in open air, creating unique surface effects and metallic finishes. Oxidation firing offers consistent, bright, and clean color results with smooth textures by allowing oxygen to fully interact with the clay and glaze during firing. The choice between these methods significantly impacts the aesthetic qualities, with raku emphasizing artistic spontaneity and oxidation delivering controlled, uniform appearances.

Required Equipment for Each Firing Method

Raku firing requires specialized equipment including a raku kiln capable of rapid heating, kiln gloves, and a reduction chamber or container filled with combustible materials for post-firing reduction. Oxidation firing typically uses electric or gas kilns that provide controlled airflow to maintain oxygen-rich conditions, alongside standard kiln furniture and temperature control systems. The equipment for raku emphasizes quick temperature changes and reduction atmosphere creation, whereas oxidation firing relies on stable oxygen supply and precise temperature regulation.

Safety Considerations and Precautions

Raku firing involves rapid temperature changes and open flames, requiring protective gear such as heat-resistant gloves, goggles, and proper ventilation to avoid exposure to toxic fumes and burns. Oxidation firing occurs in sealed kilns with controlled oxygen levels, making it safer but still necessitating caution with high temperatures and kiln operation protocols. Both methods demand strict adherence to safety guidelines to prevent accidents and ensure a safe working environment in ceramic studios.

Suitability for Different Clay Types

Raku firing suits porous and low-fire clays such as earthenware due to its rapid temperature changes and cooling process, which can cause cracking in denser clays. Oxidation firing is ideal for stoneware and porcelain clays, as the controlled oxygen environment ensures even heat distribution and durability. Each firing method interacts differently with clay's mineral composition, affecting glaze response and structural integrity.

Artistic Applications and Styles

Raku firing produces unique textures and crackled surfaces by rapidly cooling hot pottery in open air, ideal for wabi-sabi aesthetics and expressive, unpredictable finishes in ceramic art. Oxidation firing, performed in an oxygen-rich kiln environment, ensures bright, consistent colors and smooth surfaces, favored for detailed glazing and vibrant, controlled artistic styles. Each technique influences the final appearance and texture, shaping diverse ceramic art forms through distinct firing atmospheres.

Choosing Between Raku and Oxidation Firing

Choosing between Raku and oxidation firing depends on the desired artistic effect and surface quality. Raku firing produces unpredictable, crackled textures and metallic lusters due to rapid cooling and reduction atmosphere, making it ideal for unique, rustic ceramics. Oxidation firing offers controlled, consistent colors and smooth finishes by allowing sufficient oxygen during firing, suited for functional and decorative pottery requiring durability and detail.

Raku firing vs Oxidation firing Infographic

materialdif.com

materialdif.com