Clay exhibits a unique balance between plasticity and rigidity, allowing it to be easily shaped when wet and to harden upon drying or firing. This plasticity enables artists and craftsmen to mold intricate forms, while the rigidity after drying ensures structural stability. Understanding the interplay between these properties is essential for effective clay modeling and pottery.

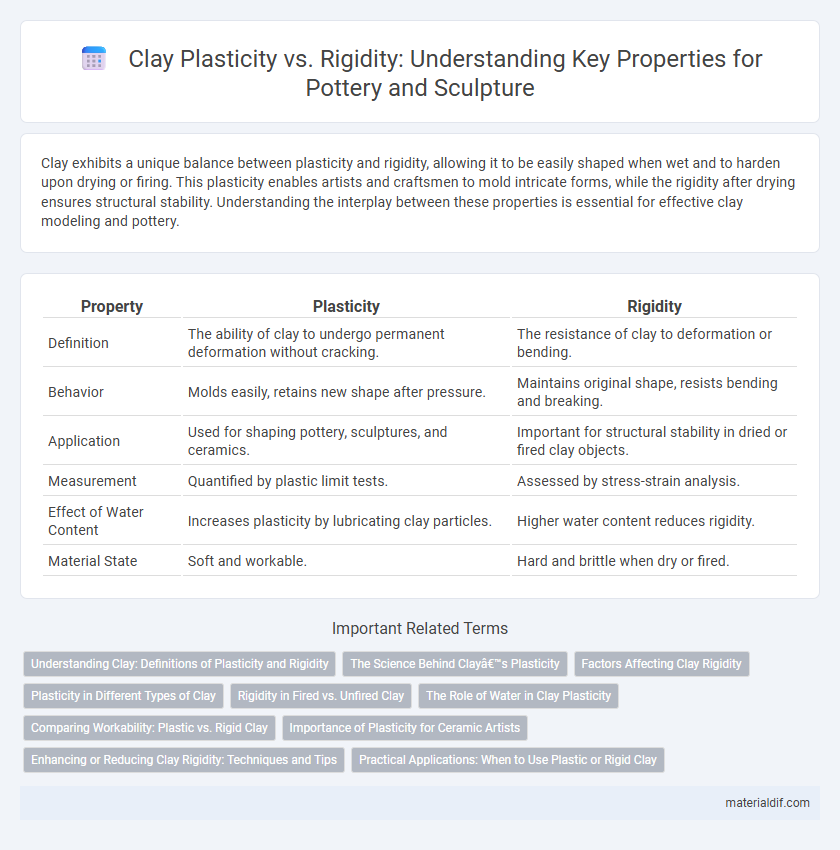

Table of Comparison

| Property | Plasticity | Rigidity |

|---|---|---|

| Definition | The ability of clay to undergo permanent deformation without cracking. | The resistance of clay to deformation or bending. |

| Behavior | Molds easily, retains new shape after pressure. | Maintains original shape, resists bending and breaking. |

| Application | Used for shaping pottery, sculptures, and ceramics. | Important for structural stability in dried or fired clay objects. |

| Measurement | Quantified by plastic limit tests. | Assessed by stress-strain analysis. |

| Effect of Water Content | Increases plasticity by lubricating clay particles. | Higher water content reduces rigidity. |

| Material State | Soft and workable. | Hard and brittle when dry or fired. |

Understanding Clay: Definitions of Plasticity and Rigidity

Plasticity in clay refers to its ability to be easily shaped and molded without cracking, characterized by the clay particles' ability to slide past each other while maintaining cohesion. Rigidity denotes the clay's resistance to deformation, where the material becomes stiff and less workable, often occurring as moisture content decreases or during the drying process. Understanding the balance between plasticity and rigidity is crucial for optimal clay manipulation in pottery, sculpture, and construction.

The Science Behind Clay’s Plasticity

Clay's plasticity results from its unique microstructure, where fine mineral particles absorb water and form a lubricated film that enables particles to slide past each other without losing cohesion. This behavior is influenced by factors such as particle size, mineral composition--primarily kaolinite, illite, and montmorillonite--and water content, which regulate the balance between plastic deformation and rigidity. Understanding the interparticle forces and the threshold moisture level is essential for optimizing clay's malleability in pottery, ceramics, and construction applications.

Factors Affecting Clay Rigidity

Clay rigidity is influenced by moisture content, where higher water levels decrease rigidity due to increased plasticity. Mineral composition, specifically the type and proportion of clay minerals such as kaolinite, montmorillonite, and illite, strongly affects rigidity by altering particle cohesion. Temperature and drying time also play crucial roles, as drying induces water loss, increasing the clay's stiffness and reducing its deformability.

Plasticity in Different Types of Clay

Plasticity in clay determines its ability to be molded and shaped without cracking or crumbling, influenced by mineral composition and water content. Kaolinite exhibits lower plasticity, making it ideal for ceramics requiring fine detail, while bentonite and montmorillonite clays display high plasticity, suited for complex sculpting and pottery. The balance of plasticity affects drying behavior, workability, and final strength of ceramic products.

Rigidity in Fired vs. Unfired Clay

Rigidity in clay significantly increases after firing due to the transformation of raw clay particles into a hardened, ceramic structure through vitrification. Unfired clay remains plastic and malleable, easily shaped but structurally weak and prone to deformation under stress or moisture. The firing process eliminates water content and chemically bonds minerals, resulting in a rigid, durable material essential for functional pottery and ceramic art.

The Role of Water in Clay Plasticity

Water acts as a critical lubricant within clay particles, facilitating the movement and rearrangement of microscopic clay platelets, which enhances the clay's plasticity. The presence of an optimal amount of water creates a thin film around these particles, reducing friction and allowing the clay to be molded and shaped easily without cracking. Too little water increases rigidity by limiting particle mobility, while too much water weakens the structure, highlighting water's essential role in balancing clay plasticity and rigidity.

Comparing Workability: Plastic vs. Rigid Clay

Plastic clay offers superior workability due to its high moisture content, allowing it to be easily shaped, molded, and manipulated without cracking. Rigid clay, with lower moisture levels and a denser composition, resists deformation and is prone to breakage during detailed work. The choice between plastic and rigid clay depends on the required flexibility for sculpting versus structural stability in the final piece.

Importance of Plasticity for Ceramic Artists

Plasticity in clay is crucial for ceramic artists as it allows the material to be easily shaped and molded without cracking or breaking. High plasticity clay enhances workability, enabling detailed sculpting and complex forms while maintaining structural integrity during drying and firing. Rigidity limits artistic expression, making plasticity essential for creating both functional and decorative ceramic pieces.

Enhancing or Reducing Clay Rigidity: Techniques and Tips

Enhancing clay rigidity can be achieved by adding grog or sand to the mixture, which improves structural strength and reduces cracking during drying and firing. Reducing rigidity often involves increasing the clay's moisture content or incorporating organic materials to promote flexibility and prevent brittleness. Mastery of these techniques allows potters to tailor clay properties for specific sculpting or molding requirements, optimizing workability and final product durability.

Practical Applications: When to Use Plastic or Rigid Clay

Plastic clay offers exceptional malleability, making it ideal for sculpting and intricate detail work in ceramics and pottery. Rigid clay, known for its firmness and ability to hold shape, suits hand-building techniques and structural components in architectural modeling or functional wares. Selecting the appropriate clay depends on project requirements such as flexibility during shaping or stability during firing and drying stages.

Plasticity vs Rigidity Infographic

materialdif.com

materialdif.com