Terracotta and kaolin clay differ significantly in composition and use for pet products, with terracotta offering a porous, rustic finish ideal for breathable pots and decorative items. Kaolin, known for its fine, white, and smooth texture, provides durability and a non-porous surface, making it suitable for pet bowls and delicate figurines. Understanding these distinctions helps in selecting the right clay for functional or aesthetic pet accessories.

Table of Comparison

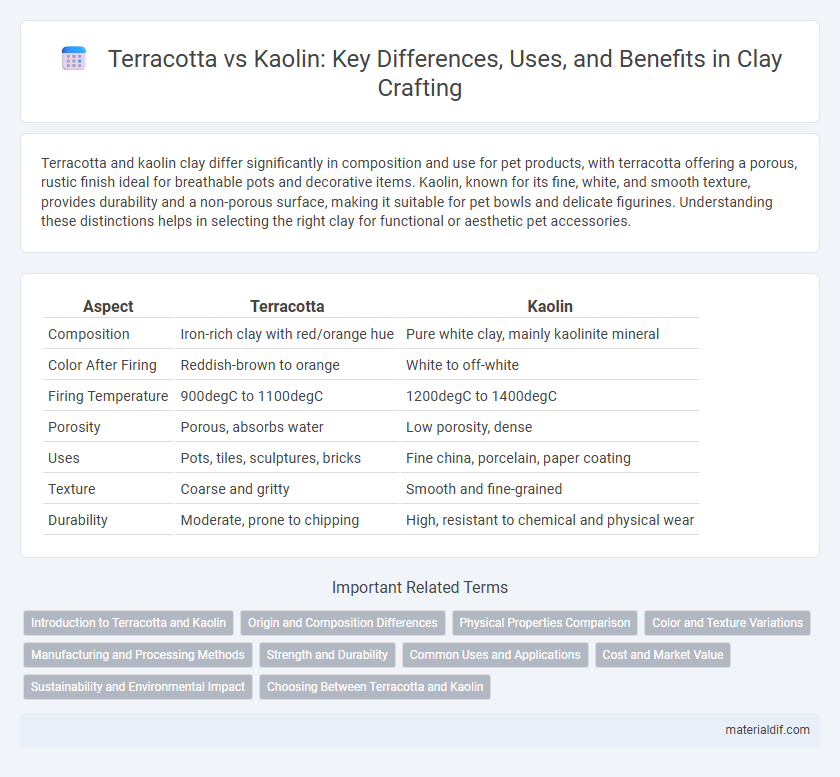

| Aspect | Terracotta | Kaolin |

|---|---|---|

| Composition | Iron-rich clay with red/orange hue | Pure white clay, mainly kaolinite mineral |

| Color After Firing | Reddish-brown to orange | White to off-white |

| Firing Temperature | 900degC to 1100degC | 1200degC to 1400degC |

| Porosity | Porous, absorbs water | Low porosity, dense |

| Uses | Pots, tiles, sculptures, bricks | Fine china, porcelain, paper coating |

| Texture | Coarse and gritty | Smooth and fine-grained |

| Durability | Moderate, prone to chipping | High, resistant to chemical and physical wear |

Introduction to Terracotta and Kaolin

Terracotta is a type of porous clay-based ceramic material primarily composed of iron-rich red clay, known for its distinctive reddish-brown color and excellent durability when fired at lower temperatures. Kaolin, also known as china clay, is a highly refined and pure white clay mineral composed mainly of kaolinite, prized for its fine particle size and high refractory properties used in porcelain and fine ceramics. Both terracotta and kaolin are essential in ceramics, with terracotta favored for rustic, earthenware objects and kaolin valued for smooth, white, and strong ceramic products.

Origin and Composition Differences

Terracotta originates from natural iron-rich clays, primarily composed of a mixture of silica, alumina, and iron oxide, giving it its characteristic reddish-orange hue due to iron content oxidation. Kaolin, also known as china clay, is a pure, white clay composed mainly of the mineral kaolinite, formed from the chemical weathering of aluminum silicate minerals. The primary compositional difference lies in terracotta's high iron oxide content versus kaolin's purity and lack of coloring minerals, influencing their distinct appearance and firing properties.

Physical Properties Comparison

Terracotta exhibits a porous, reddish-brown structure due to its iron content and lower firing temperatures, resulting in a more brittle and less dense material compared to kaolin. Kaolin, also known as china clay, has a fine, white, and non-porous texture with higher plasticity and strength after firing at high temperatures, allowing for a smoother, more durable finish. The physical durability and water absorption rates significantly differ, with terracotta being more absorbent and less resistant to wear than dense, vitrified kaolin-based ceramics.

Color and Texture Variations

Terracotta clay exhibits a characteristic reddish-brown color due to its high iron content, while kaolin features a pristine white to off-white hue, attributed to its purity and low iron levels. The texture of terracotta is coarse and gritty, ideal for rustic pottery and sculpture, contrasting with kaolin's fine, smooth, and powdery consistency, which enables delicate porcelain and refined ceramics. These differences in color and texture directly influence their usability in artistic and functional clay applications.

Manufacturing and Processing Methods

Terracotta is manufactured by shaping coarse natural clay and firing it at relatively low temperatures around 1000degC, resulting in a porous, reddish material ideal for pottery and sculptures. Kaolin, a refined white clay composed mainly of kaolinite, undergoes extensive processing including washing, centrifuging, and calcining to remove impurities and achieve a high purity, fine particle size suitable for porcelain production and specialized ceramics. The distinct processing methods reflect terracotta's rustic texture and kaolin's smooth, vitrified finish, influencing their diverse applications in manufacturing.

Strength and Durability

Terracotta, made from iron-rich clay, offers moderate strength with a porous structure that absorbs moisture, making it less durable in freeze-thaw cycles. Kaolin, a pure white clay with a fine particle size, provides superior strength and durability due to its dense composition and resistance to chemical weathering. Products crafted from kaolin exhibit enhanced longevity and higher mechanical robustness compared to terracotta items.

Common Uses and Applications

Terracotta clay is widely used for pottery, sculptures, and architectural elements due to its porous nature and warm, reddish-brown color after firing, making it ideal for decorative art and garden ornaments. Kaolin clay, known for its fine texture and high purity, is primarily used in ceramics, porcelain production, paper coating, and cosmetics, offering smooth surface finishes and resistance to high temperatures. The distinct mineral composition of terracotta makes it suitable for rustic, earthy items, while kaolin's chemical stability favors industrial and artistic applications requiring precision and durability.

Cost and Market Value

Terracotta is a cost-effective clay material widely used in pottery and construction due to its abundant natural availability and lower processing expenses. Kaolin, also known as china clay, commands a higher market value because of its purity, fine particle size, and extensive applications in ceramics, paper, and cosmetics. The price difference between terracotta and kaolin reflects their distinct structural characteristics and industrial demand, influencing their respective market positions.

Sustainability and Environmental Impact

Terracotta, made from natural red clay, requires lower firing temperatures, reducing energy consumption and carbon emissions compared to the high-fired, pure kaolin porcelain. Kaolin extraction often involves significant land disruption and water use, whereas terracotta production tends to have a smaller ecological footprint due to more abundant local clay sources and simpler processing. Both materials are biodegradable, but terracotta's traditional, less energy-intensive manufacturing process offers greater sustainability benefits in eco-conscious pottery and construction applications.

Choosing Between Terracotta and Kaolin

Choosing between terracotta and kaolin depends on the desired durability and finish of the ceramic piece. Terracotta, with its porous texture and rich reddish-brown hue, suits rustic pottery and garden planters, while kaolin offers a finer, whiter, and more vitrified surface ideal for porcelain and fine china. The higher firing temperature and purity of kaolin clay make it preferable for projects requiring strength and translucency.

Terracotta vs Kaolin Infographic

materialdif.com

materialdif.com