Ceramic bisque firing is the initial firing process that transforms raw clay into a porous, durable state suitable for glazing while removing moisture and organic materials. Glaze firing, conducted at higher temperatures, melts the applied glaze to form a smooth, glass-like coating that seals and decorates the ceramic piece. Understanding the differences between bisque and glaze firing is essential for achieving optimal strength, finish, and functionality in ceramic artworks.

Table of Comparison

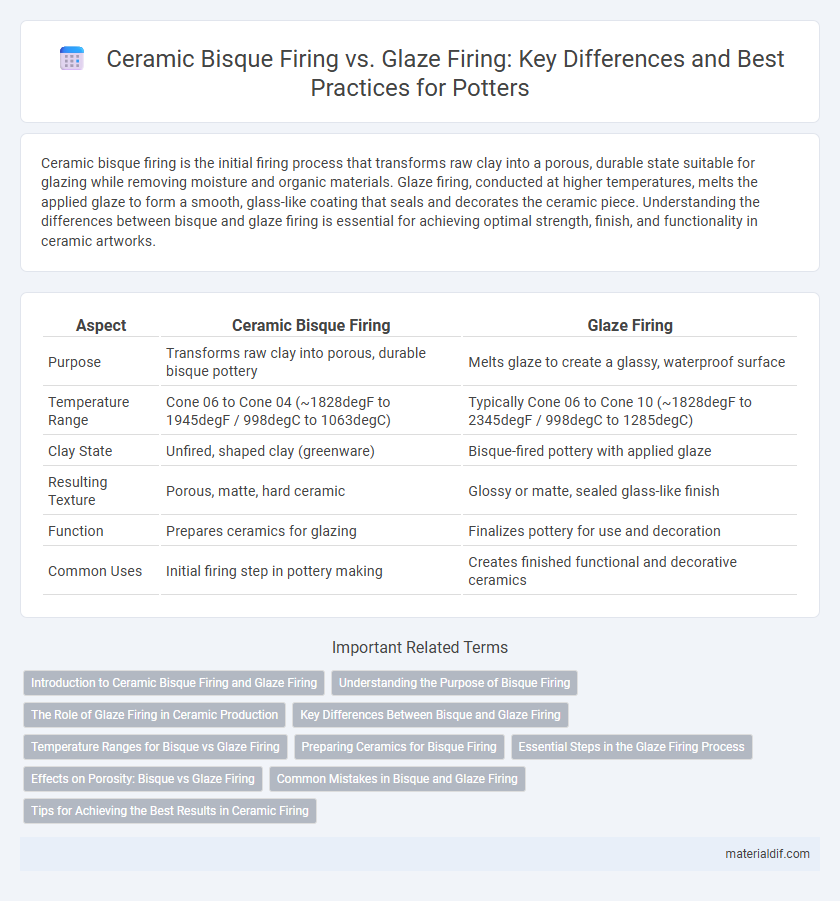

| Aspect | Ceramic Bisque Firing | Glaze Firing |

|---|---|---|

| Purpose | Transforms raw clay into porous, durable bisque pottery | Melts glaze to create a glassy, waterproof surface |

| Temperature Range | Cone 06 to Cone 04 (~1828degF to 1945degF / 998degC to 1063degC) | Typically Cone 06 to Cone 10 (~1828degF to 2345degF / 998degC to 1285degC) |

| Clay State | Unfired, shaped clay (greenware) | Bisque-fired pottery with applied glaze |

| Resulting Texture | Porous, matte, hard ceramic | Glossy or matte, sealed glass-like finish |

| Function | Prepares ceramics for glazing | Finalizes pottery for use and decoration |

| Common Uses | Initial firing step in pottery making | Creates finished functional and decorative ceramics |

Introduction to Ceramic Bisque Firing and Glaze Firing

Ceramic bisque firing is the initial kiln firing process that transforms raw clay into a porous, hardened state, making it durable yet absorbent for glazing. Glaze firing follows, where the bisque-fired piece is coated with glaze and heated to a higher temperature, causing the glaze to vitrify and form a glass-like surface. Understanding the temperature ranges and chemical changes during bisque and glaze firings is essential for achieving desired ceramic finishes and durability.

Understanding the Purpose of Bisque Firing

Bisque firing transforms raw clay into a porous, durable state that allows glaze to adhere properly during glaze firing. This initial firing removes physical and chemical water, strengthening the ceramic piece without vitrifying it, which is crucial for subsequent glazing processes. Understanding bisque firing highlights its role in preparing ceramics for glaze application, ensuring both durability and aesthetic quality in the final product.

The Role of Glaze Firing in Ceramic Production

Glaze firing plays a crucial role in ceramic production by transforming the applied glaze into a smooth, glass-like surface that enhances both the aesthetic appeal and functionality of ceramic pieces. This firing process occurs at higher temperatures than bisque firing, causing chemical reactions that fuse the glaze to the ceramic body, sealing its porous surface and improving durability. Proper glaze firing ensures color vibrancy, surface texture, and water resistance, making it essential for the final quality and performance of ceramics.

Key Differences Between Bisque and Glaze Firing

Bisque firing transforms raw clay into a porous, hardened ceramic by heating it to around bisque temperatures of bisque temperatures of bisque temperatures of bisque temperatures of bisque temperatures of bisque temperatures of bisque temperatures of bisque temperatures of bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of approximately bisque temperatures of 1800degF to 1940degF (982degC to 1060degC), eliminating chemical water and organic materials to prepare the piece for glazing. Glaze firing occurs at higher temperatures, typically between 2167degF and 2345degF (1186degC to 1285degC), causing the glaze to mature and fuse to the bisque ware, creating a glass-like, waterproof surface. Key differences include the firing temperature range, the physical state of the ceramic (porous bisque vs. vitrified glaze), and the functional purpose--bisque firing strengthens and readies the piece for glazing, while glaze firing finalizes the ceramic's durability and aesthetics.

Temperature Ranges for Bisque vs Glaze Firing

Ceramic bisque firing typically occurs at lower temperatures, ranging from 1730degF to 1940degF (945degC to 1060degC), which drives out moisture and hardens the clay body without vitrifying it. Glaze firing requires higher temperatures between 1830degF and 2340degF (1000degC to 1280degC), depending on the glaze type, to melt and fuse the glaze onto the ceramic surface. Understanding these temperature ranges is essential for achieving proper durability and finished aesthetics in ceramic pieces.

Preparing Ceramics for Bisque Firing

Preparing ceramics for bisque firing involves thoroughly drying the clay pieces to prevent steam explosions in the kiln. Ensuring uniform thickness and removing all air bubbles during the forming process reduces the risk of cracks or breakage during bisque firing. Properly cleaning and scoring the bisque ware also prepares the surface for optimal glaze adhesion in the subsequent glaze firing stage.

Essential Steps in the Glaze Firing Process

Glaze firing is a critical ceramic process where the glaze melts and bonds to the bisque-fired clay body, creating a glass-like surface. Essential steps include loading the kiln with bisque-fired pieces, carefully controlling the temperature ramp to avoid thermal shock, and reaching the target maturation temperature typically between 1,200degC to 1,300degC, depending on the glaze type. Cooling must be gradual to prevent cracking, ensuring the glaze finishes with the desired texture, color, and durability.

Effects on Porosity: Bisque vs Glaze Firing

Bisque firing transforms raw ceramic clay into a porous, hardened state by heating to approximately bisque temperatures around bisque firing temperature ranges typically cone 06 to bisque firing to cone 06 (around 1828degF or 998degC), which drives out chemical water and organic material while maintaining porosity. Glaze firing occurs at higher temperatures, usually cone 6 to cone 10 (about 2232degF to 2345degF or 1222degC to 1285degC), where the application of glaze melts and vitrifies the surface, significantly reducing porosity by sealing the ceramic body. The contrast in porosity between bisque-fired and glaze-fired ceramics affects the piece's absorption characteristics and durability, with bisque ware remaining absorbent and glaze-fired ware achieving a non-porous, glass-like finish.

Common Mistakes in Bisque and Glaze Firing

Common mistakes during bisque firing include firing too quickly, causing thermal shock and cracks, or underfiring, which leaves bisque ware too fragile for glazing. In glaze firing, errors like applying excessively thick or uneven glaze can lead to drips, pinholes, or poor surface finish, while firing beyond the clay body's maturity temperature often results in warping or melting. Proper kiln temperature control and understanding the clay and glaze composition are crucial to avoid these typical defects in both bisque and glaze firing stages.

Tips for Achieving the Best Results in Ceramic Firing

Achieving the best results in ceramic firing requires careful control of bisque and glaze firing temperatures, typically ranging between bisque firing at cone 06 (1828degF/998degC) and glaze firing between cone 05 to cone 10 (1888degF/1940degF or 1030degC/1060degC). Ensure slow, even heating to prevent cracking or warping during bisque firing and maintain proper kiln atmosphere during glaze firing to enhance color vibrancy and glaze finish quality. Using calibrated pyrometric cones and conducting test firings can optimize firing schedules and improve the consistency of both bisque and glaze firings.

Ceramic Bisque Firing vs Glaze Firing Infographic

materialdif.com

materialdif.com