Ceramic tile and porcelain tile differ primarily in composition and durability, with porcelain being denser, less porous, and more resistant to moisture and wear. Porcelain tiles are ideal for high-traffic areas and outdoor use due to their enhanced strength, while ceramic tiles suit low-traffic spaces and indoor applications. Both offer a wide range of design options, but porcelain's superior hardness makes it a longer-lasting choice.

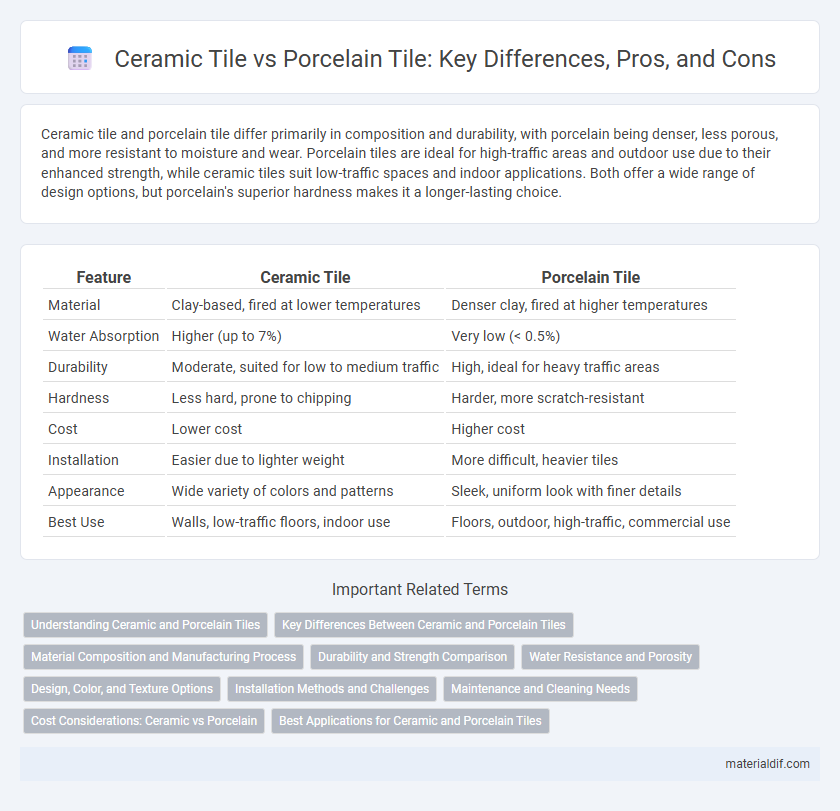

Table of Comparison

| Feature | Ceramic Tile | Porcelain Tile |

|---|---|---|

| Material | Clay-based, fired at lower temperatures | Denser clay, fired at higher temperatures |

| Water Absorption | Higher (up to 7%) | Very low (< 0.5%) |

| Durability | Moderate, suited for low to medium traffic | High, ideal for heavy traffic areas |

| Hardness | Less hard, prone to chipping | Harder, more scratch-resistant |

| Cost | Lower cost | Higher cost |

| Installation | Easier due to lighter weight | More difficult, heavier tiles |

| Appearance | Wide variety of colors and patterns | Sleek, uniform look with finer details |

| Best Use | Walls, low-traffic floors, indoor use | Floors, outdoor, high-traffic, commercial use |

Understanding Ceramic and Porcelain Tiles

Ceramic tiles are made from natural clay fired at lower temperatures, resulting in a porous material suitable for low-traffic areas, while porcelain tiles are crafted from denser clay fired at higher temperatures, offering superior durability and water resistance ideal for high-moisture environments. Porcelain tiles have a lower water absorption rate, typically less than 0.5%, compared to ceramic's higher rate, making porcelain tiles more suitable for bathrooms and outdoor areas. Understanding these differences helps in selecting the right tile based on performance requirements, cost, and aesthetic preferences.

Key Differences Between Ceramic and Porcelain Tiles

Ceramic tiles are typically made from red or white clay and fired at lower temperatures, resulting in a porous surface that requires sealing, whereas porcelain tiles are denser, made from refined clay, and fired at higher temperatures for enhanced durability and water resistance. Porcelain tiles have a lower water absorption rate of less than 0.5%, making them ideal for high-moisture areas, while ceramic tiles have higher absorption, suited for low-traffic, dry areas. The hardness of porcelain tiles, measured on the Mohs scale, is generally higher than ceramic, contributing to superior scratch and wear resistance.

Material Composition and Manufacturing Process

Ceramic tiles are made primarily from red or white clay fired at lower temperatures, resulting in a more porous and softer material. Porcelain tiles, composed of finer, denser clay and minerals like kaolin, feldspar, and quartz, undergo higher-temperature firing that creates a vitrified, harder surface with reduced porosity. The manufacturing process for porcelain involves sintering at temperatures above 1200degC, which enhances durability and water resistance compared to the typically less dense ceramic tile fired below 1100degC.

Durability and Strength Comparison

Porcelain tiles have higher density and lower water absorption rates, making them more durable and resistant to cracking compared to ceramic tiles. Ceramic tiles, while more affordable, are softer and more prone to chipping and wear over time, especially in high-traffic areas. The strength of porcelain tiles makes them suitable for both indoor and outdoor use, whereas ceramic is generally recommended for indoor applications.

Water Resistance and Porosity

Porcelain tiles have significantly lower porosity, typically less than 0.5%, making them highly water-resistant and ideal for wet areas like bathrooms and kitchens. Ceramic tiles usually possess higher porosity, around 3-7%, which makes them more susceptible to water absorption and less suitable for environments with high moisture exposure. The denser composition of porcelain tiles ensures better durability and reduced risk of water damage compared to ceramic alternatives.

Design, Color, and Texture Options

Ceramic tiles offer a wider variety of design options with vibrant colors and intricate patterns due to their porous nature, making them ideal for decorative applications. Porcelain tiles, denser and less porous, provide more consistent textures and often mimic natural stone or wood with subtle, elegant finishes suitable for both indoor and outdoor use. Both materials support digital printing technology, enhancing customization possibilities in color gradients and surface textures to match diverse aesthetic preferences.

Installation Methods and Challenges

Ceramic tile installation generally involves simpler techniques such as thin-set mortar application and grout, while porcelain tile requires more precise methods due to its denser composition and lower water absorption rate. Porcelain tiles often necessitate specialized wet saws with diamond blades to prevent cracking, and the subfloor must be perfectly level to avoid installation issues. Both materials face challenges in ensuring proper adhesion and grout sealing, but porcelain demands greater skill and precision during cutting and handling.

Maintenance and Cleaning Needs

Ceramic tiles require regular sealing and are more prone to staining due to their porous nature, making frequent cleaning essential with mild detergents and water. Porcelain tiles, being denser and less porous, offer superior stain resistance and durability, demanding less maintenance and allowing for easier cleaning with standard household cleaners. Both materials benefit from routine sweeping and mopping to prevent dirt buildup, but porcelain's low absorption rate significantly reduces the risk of damage from moisture and chemicals.

Cost Considerations: Ceramic vs Porcelain

Ceramic tiles typically cost less than porcelain tiles due to differences in manufacturing processes and material density. Porcelain tile's denser composition and higher firing temperatures contribute to its increased durability and price, often doubling the cost of ceramic options. Factoring in installation expenses, porcelain tiles may require more specialized labor, further impacting the overall investment compared to more budget-friendly ceramic alternatives.

Best Applications for Ceramic and Porcelain Tiles

Ceramic tiles are best suited for low-moisture areas like walls, backsplashes, and light-traffic residential floors due to their porous nature and affordability. Porcelain tiles, known for their density and water resistance, excel in high-moisture environments such as bathrooms, kitchens, and outdoor spaces, as well as heavy-traffic commercial floors. Selecting porcelain tiles enhances durability and stain resistance, while ceramic tiles offer versatile design options for aesthetic-focused interior applications.

Ceramic Tile vs Porcelain Tile Infographic

materialdif.com

materialdif.com