Raku firing involves removing ceramics from the kiln while hot and cooling them rapidly, which creates unique crackled textures and unpredictable glaze effects. Kiln firing, in contrast, heats ceramics slowly and cools them gradually in a controlled environment, resulting in more uniform and durable finishes. The choice between raku and kiln firing affects the final appearance, strength, and artistic expression of the ceramic piece.

Table of Comparison

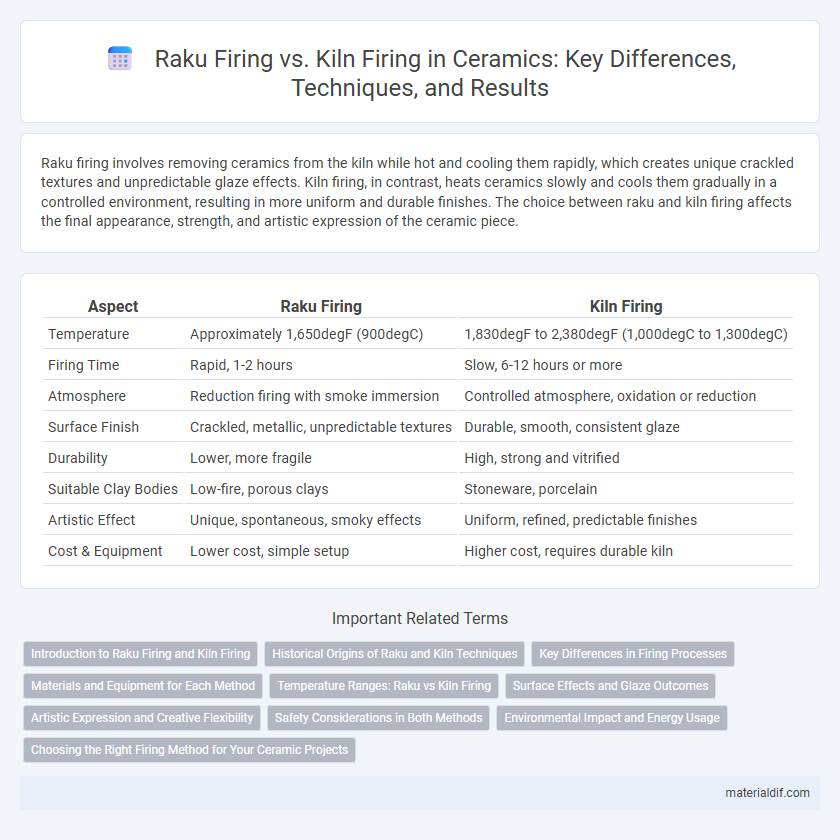

| Aspect | Raku Firing | Kiln Firing |

|---|---|---|

| Temperature | Approximately 1,650degF (900degC) | 1,830degF to 2,380degF (1,000degC to 1,300degC) |

| Firing Time | Rapid, 1-2 hours | Slow, 6-12 hours or more |

| Atmosphere | Reduction firing with smoke immersion | Controlled atmosphere, oxidation or reduction |

| Surface Finish | Crackled, metallic, unpredictable textures | Durable, smooth, consistent glaze |

| Durability | Lower, more fragile | High, strong and vitrified |

| Suitable Clay Bodies | Low-fire, porous clays | Stoneware, porcelain |

| Artistic Effect | Unique, spontaneous, smoky effects | Uniform, refined, predictable finishes |

| Cost & Equipment | Lower cost, simple setup | Higher cost, requires durable kiln |

Introduction to Raku Firing and Kiln Firing

Raku firing is a rapid ceramic firing process originating from Japan, involving removing pottery from the kiln while it is red-hot and cooling it quickly in open air or combustible materials, resulting in unique textures and crackled glazes. Kiln firing, by contrast, is a controlled, slower process where ceramics are fired at high temperatures inside a kiln, allowing for even heat distribution and consistent glaze maturation. Understanding the differences between Raku and kiln firing offers insights into their effects on clay bodies, glaze characteristics, and the final aesthetic of ceramic art.

Historical Origins of Raku and Kiln Techniques

Raku firing originated in 16th-century Japan, characterized by its low-temperature, rapid cooling process that produces unique glaze effects and cracks, deeply rooted in the Japanese tea ceremony tradition. Kiln firing, with origins tracing back to ancient civilizations such as Mesopotamia and Egypt, employs controlled high temperatures within enclosed chambers to harden ceramics consistently and uniformly. These distinct historical techniques reflect cultural priorities: raku emphasizing spontaneity and aesthetic unpredictability, while kiln firing prioritizes durability and precision.

Key Differences in Firing Processes

Raku firing involves rapid heating and cooling outside the kiln, producing unique crackle patterns due to thermal shock, while kiln firing uses controlled, gradual temperature changes within a stationary kiln for consistent durability. Raku firing typically reaches temperatures around 1,650degF (900degC), whereas kiln firing can reach higher temperatures up to 2,300degF (1,260degC), enabling different clay maturity and glaze effects. The unpredictable nature of raku creates one-of-a-kind finishes, contrasting with the uniform surface achieved through kiln firing.

Materials and Equipment for Each Method

Raku firing employs porous, low-fire ceramics and uses a specialized raku kiln designed for rapid heating and cooling, often reaching temperatures around 1,650degF (900degC). Kiln firing typically involves high-fire stoneware or porcelain and relies on traditional electric or gas kilns capable of sustaining temperatures up to 2,400degF (1,300degC) for prolonged periods. Both methods require different materials: raku clay with low thermal shock resistance and kiln firing clay formulated for durability and higher maturation points.

Temperature Ranges: Raku vs Kiln Firing

Raku firing typically occurs at lower temperatures ranging from 1,650degF to 1,850degF (900degC to 1,010degC), allowing for rapid cooling and unique surface effects. Kiln firing reaches much higher temperatures, often between 2,100degF and 2,400degF (1,150degC to 1,315degC), resulting in stronger, more durable ceramics. The distinct temperature ranges influence the final texture, strength, and color variations of the ceramic pieces.

Surface Effects and Glaze Outcomes

Raku firing produces unique surface effects characterized by crackled textures and unpredictable glaze patterns due to rapid cooling and smoke exposure, enhancing tactile and visual contrast. Kiln firing offers controlled temperature environments that yield smooth, glossy glazes with consistent texture and color uniformity across ceramic pieces. The distinct firing atmospheres in Raku and kiln methods significantly influence glaze maturation, surface sheen, and durability.

Artistic Expression and Creative Flexibility

Raku firing offers unmatched artistic expression through rapid cooling and unpredictable glaze effects, allowing artists to embrace spontaneity and unique surface textures. Kiln firing provides controlled, consistent temperatures facilitating precise color outcomes and detailed finishes critical for intricate designs. Creative flexibility thrives in Raku's dynamic process, while kiln firing supports meticulous and repeatable ceramic art production.

Safety Considerations in Both Methods

Raku firing involves rapid heating and cooling, which can cause thermal shock and increase the risk of burns, requiring careful handling and protective gear. Kiln firing operates at controlled, stable temperatures, reducing immediate hazards but necessitating proper ventilation due to potential toxic fumes from glaze materials. Both methods demand strict adherence to safety protocols, including using heat-resistant gloves, eye protection, and ensuring proper airflow to minimize exposure to harmful emissions.

Environmental Impact and Energy Usage

Raku firing consumes less energy than kiln firing due to its rapid heating and cooling process, reducing overall fuel consumption and carbon emissions. Kiln firing, requiring prolonged high temperatures and controlled atmospheres, results in higher energy usage and greater environmental impact. The choice between these firing methods significantly influences the sustainability profile of ceramic production.

Choosing the Right Firing Method for Your Ceramic Projects

Raku firing offers rapid results and unique, unpredictable glaze effects ideal for artistic, small-batch ceramics, while kiln firing provides consistent high-temperature control necessary for durable, functional pieces. Selecting between raku and kiln firing depends on your project's desired aesthetic, durability requirements, and material compatibility, such as clay body and glaze type. Understanding each method's temperature range--raku typically around 1,650degF (900degC) versus kiln firing up to 2,380degF (1,300degC)--ensures optimal results tailored to your ceramic art or functional wares.

Raku Firing vs Kiln Firing Infographic

materialdif.com

materialdif.com