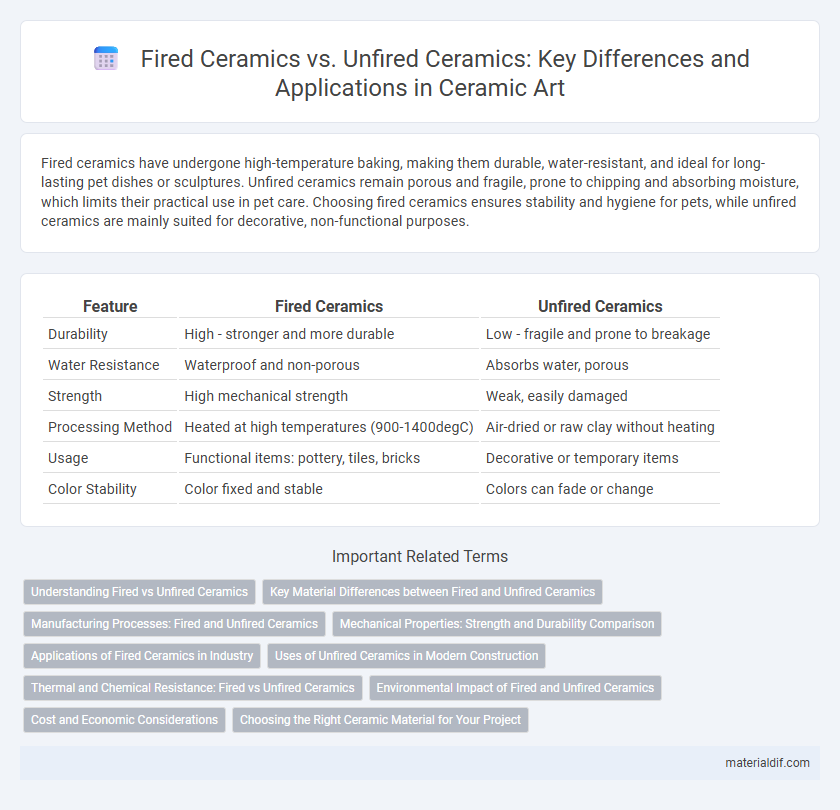

Fired ceramics have undergone high-temperature baking, making them durable, water-resistant, and ideal for long-lasting pet dishes or sculptures. Unfired ceramics remain porous and fragile, prone to chipping and absorbing moisture, which limits their practical use in pet care. Choosing fired ceramics ensures stability and hygiene for pets, while unfired ceramics are mainly suited for decorative, non-functional purposes.

Table of Comparison

| Feature | Fired Ceramics | Unfired Ceramics |

|---|---|---|

| Durability | High - stronger and more durable | Low - fragile and prone to breakage |

| Water Resistance | Waterproof and non-porous | Absorbs water, porous |

| Strength | High mechanical strength | Weak, easily damaged |

| Processing Method | Heated at high temperatures (900-1400degC) | Air-dried or raw clay without heating |

| Usage | Functional items: pottery, tiles, bricks | Decorative or temporary items |

| Color Stability | Color fixed and stable | Colors can fade or change |

Understanding Fired vs Unfired Ceramics

Fired ceramics undergo a high-temperature heating process that causes chemical and physical changes, resulting in increased strength, durability, and water resistance compared to unfired ceramics. Unfired ceramics, often referred to as greenware, remain porous and fragile due to the lack of vitrification, making them susceptible to damage and water absorption. Understanding the differences in firing temperature, mineral composition, and resulting material properties is essential for applications in pottery, construction, and industrial ceramics.

Key Material Differences between Fired and Unfired Ceramics

Fired ceramics undergo a kiln-firing process that transforms clay into a durable, vitrified material with enhanced hardness, water resistance, and thermal stability. Unfired ceramics, such as raw clay or air-dried pottery, remain porous and fragile due to the absence of heat-induced chemical changes, resulting in lower mechanical strength and susceptibility to moisture damage. The primary material difference lies in the microstructural transformation during firing, which causes sintering and phase changes that solidify the ceramic matrix.

Manufacturing Processes: Fired and Unfired Ceramics

Fired ceramics undergo high-temperature kiln processes that induce chemical and physical changes, resulting in a hardened, durable, and water-resistant material ideal for structural and functional applications. Unfired ceramics, also known as greenware, lack this thermal alteration and remain fragile, porous, and sensitive to moisture, limiting their use primarily to decorative or temporary purposes. The manufacturing process of fired ceramics involves precise temperature control and prolonged heating, which vitrifies the clay matrix and enhances mechanical strength compared to the drying and shaping steps used for unfired ceramics.

Mechanical Properties: Strength and Durability Comparison

Fired ceramics exhibit significantly higher mechanical strength and durability compared to unfired ceramics due to the sintering process, which densifies the material and reduces porosity. This enhanced microstructure in fired ceramics leads to improved resistance to wear, fracture toughness, and long-term stability under mechanical stress. In contrast, unfired ceramics remain fragile and brittle with lower compressive strength, making them unsuitable for structural or load-bearing applications.

Applications of Fired Ceramics in Industry

Fired ceramics exhibit enhanced durability, heat resistance, and mechanical strength, making them ideal for applications in aerospace, electronics, and biomedical industries. These materials are commonly used in engine components, insulators, cutting tools, and dental implants due to their ability to withstand high temperatures and corrosive environments. Unfired ceramics lack these properties, limiting their industrial use primarily to art and prototype models.

Uses of Unfired Ceramics in Modern Construction

Unfired ceramics, such as adobe, rammed earth, and unfired clay bricks, are increasingly used in modern construction for sustainable building solutions due to their low energy footprint and excellent thermal insulation properties. These materials provide natural humidity regulation and contribute to healthier indoor environments while minimizing environmental impact compared to fired ceramics. Advances in stabilization techniques with additives like lime or cement improve the durability and weather resistance of unfired ceramics, making them viable for walls, partitions, and eco-friendly housing projects.

Thermal and Chemical Resistance: Fired vs Unfired Ceramics

Fired ceramics exhibit significantly higher thermal and chemical resistance compared to unfired ceramics due to the sintering process that densifies and strengthens the material. The elevated temperatures in firing create a stable crystalline structure, making fired ceramics more resistant to heat, acids, and moisture. Unfired ceramics remain porous and chemically reactive, limiting their durability and suitability for high-temperature or corrosive environments.

Environmental Impact of Fired and Unfired Ceramics

Fired ceramics exhibit greater durability and water resistance, reducing the need for frequent replacement and minimizing resource consumption over time, whereas unfired ceramics, being more biodegradable, decompose naturally but often lack long-term durability. The firing process consumes significant energy and emits carbon dioxide, contributing to environmental pollution, while unfired ceramics involve lower immediate energy use but potentially greater waste generation due to fragility. Balancing the environmental impact requires considering the lifecycle emissions and resource use associated with manufacturing, usage, and disposal of both fired and unfired ceramic materials.

Cost and Economic Considerations

Fired ceramics typically incur higher production costs due to energy-intensive kiln firing, which increases overall manufacturing expenses but results in durable, long-lasting products. Unfired ceramics, while cheaper to produce because they skip the firing stage, often lack durability and structural integrity, limiting their economic lifespan and potential applications. Choosing between fired and unfired ceramics depends on balancing upfront costs with product performance and longevity requirements.

Choosing the Right Ceramic Material for Your Project

Fired ceramics offer enhanced durability, water resistance, and structural strength due to the high-temperature vitrification process, making them ideal for functional and load-bearing applications such as pottery and tiles. Unfired ceramics, including clay and raw porcelain, remain porous and fragile, suitable primarily for artistic projects, prototypes, or decorative pieces where detail and malleability are prioritized. Selecting the right ceramic material depends on the project's requirements for strength, moisture resistance, and longevity, ensuring the finished product meets performance and aesthetic goals.

Fired ceramics vs Unfired ceramics Infographic

materialdif.com

materialdif.com