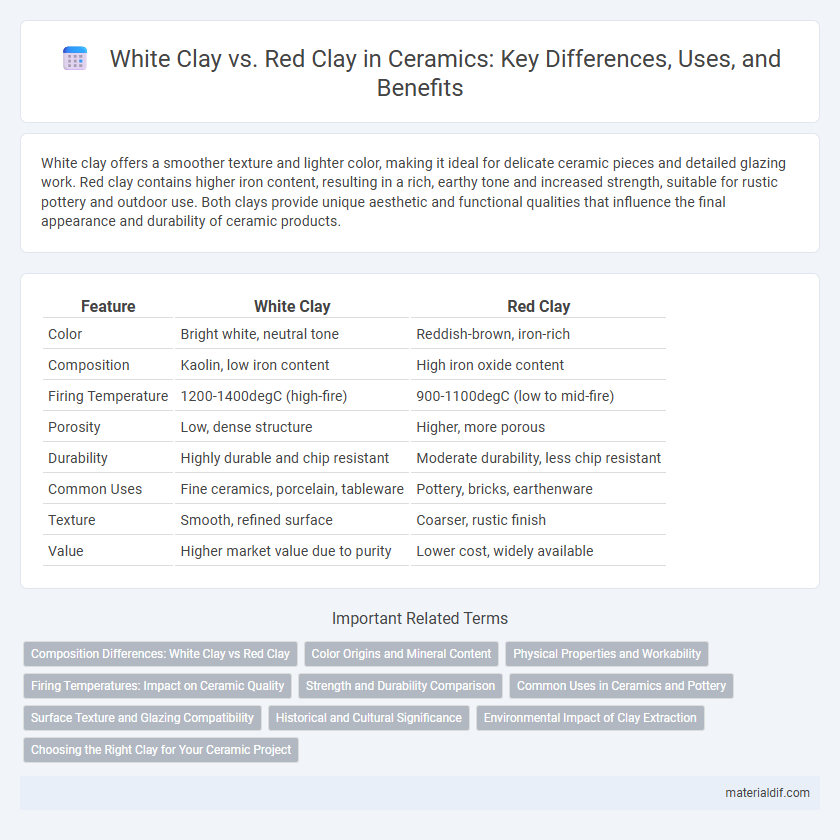

White clay offers a smoother texture and lighter color, making it ideal for delicate ceramic pieces and detailed glazing work. Red clay contains higher iron content, resulting in a rich, earthy tone and increased strength, suitable for rustic pottery and outdoor use. Both clays provide unique aesthetic and functional qualities that influence the final appearance and durability of ceramic products.

Table of Comparison

| Feature | White Clay | Red Clay |

|---|---|---|

| Color | Bright white, neutral tone | Reddish-brown, iron-rich |

| Composition | Kaolin, low iron content | High iron oxide content |

| Firing Temperature | 1200-1400degC (high-fire) | 900-1100degC (low to mid-fire) |

| Porosity | Low, dense structure | Higher, more porous |

| Durability | Highly durable and chip resistant | Moderate durability, less chip resistant |

| Common Uses | Fine ceramics, porcelain, tableware | Pottery, bricks, earthenware |

| Texture | Smooth, refined surface | Coarser, rustic finish |

| Value | Higher market value due to purity | Lower cost, widely available |

Composition Differences: White Clay vs Red Clay

White clay primarily consists of kaolinite, a pure, fine-grained mineral with minimal iron content, resulting in its light color and smooth texture ideal for porcelain and delicate ceramics. Red clay contains significant amounts of iron oxide, which imparts its characteristic reddish hue and contributes to its coarser grain and higher plasticity, making it suitable for terracotta and earthenware. These compositional differences affect firing temperatures, porosity, and final product durability in ceramic applications.

Color Origins and Mineral Content

White clay, also known as kaolin, derives its pale color from a high concentration of kaolinite mineral and low iron oxide content, making it ideal for porcelain and fine ceramics. Red clay obtains its distinctive color from iron oxide, particularly hematite, which imparts rich red and reddish-brown hues used in terracotta and rustic pottery. The mineral composition directly influences not only the color but also the firing temperature and porosity of the ceramic products.

Physical Properties and Workability

White clay, also known as kaolin, is characterized by its fine particle size, high plasticity, and smooth texture, making it ideal for detailed ceramic work and porcelain production. Red clay contains higher iron oxide content, giving it its distinct color and resulting in a coarser texture with moderate plasticity suited for pottery and brick-making. White clay's low shrinkage and high firing temperature contrast with red clay's increased porosity and lower vitrification point, affecting the final strength and finish of ceramic products.

Firing Temperatures: Impact on Ceramic Quality

White clay typically requires higher firing temperatures, ranging from 1200degC to 1400degC, resulting in denser and more vitrified ceramics with a fine, white finish. Red clay fires at lower temperatures, usually between 900degC and 1100degC, producing more porous and less durable ceramics that retain their characteristic reddish hue due to iron oxide content. The different firing temperatures directly affect the clay's shrinkage, porosity, and final strength, making white clay suitable for high-quality porcelain-like products while red clay is preferred for rustic pottery and terracotta items.

Strength and Durability Comparison

White clay typically exhibits higher purity with fewer impurities, resulting in a denser and more vitrified ceramic body that offers superior strength and durability compared to red clay. Red clay contains iron oxides, which can introduce porosity and reduce mechanical strength but may provide better thermal shock resistance in some cases. Strength tests show white clay ceramic products generally achieve higher compressive and flexural strength values, making them ideal for structural and high-wear applications.

Common Uses in Ceramics and Pottery

White clay, often kaolin, is prized for its fine texture and high firing temperature, making it ideal for porcelain, sanitaryware, and fine china production. Red clay contains iron oxide, providing durability and rich color, commonly used in terracotta, bricks, and traditional pottery that requires less refinement. Both clays serve distinct purposes shaped by their mineral composition, influencing the strength, color, and texture of ceramic products.

Surface Texture and Glazing Compatibility

White clay offers a smoother surface texture, enhancing fine detail work and providing an ideal base for transparent or light-colored glazes that highlight intricate designs. Red clay features a coarser, grainier texture with natural iron content, which influences the adhesion and color response of glazes, often resulting in richer, earthy finishes. Both clays require specific glaze formulations to optimize bond strength and aesthetic outcome, with white clay favoring glossy and delicate glazes, while red clay complements matte and rustic glaze styles.

Historical and Cultural Significance

White clay, historically prized in East Asian ceramics, was integral to the creation of refined porcelain celebrated for its purity and translucence, reflecting sophistication in dynastic art. Red clay, predominantly used in regions like the Mediterranean and Africa, embodies earthiness and tradition, often featured in utilitarian pottery and ritual artifacts symbolizing cultural identity. Both clays illustrate distinct historical journeys and cultural values, with white clay linked to luxury and red clay to communal heritage.

Environmental Impact of Clay Extraction

White clay extraction generally has a lower environmental impact than red clay due to its less intensive mining processes and reduced soil degradation. Red clay mining often involves deeper excavation and contributes to higher levels of land erosion and habitat disruption. Sustainable clay sourcing and rehabilitation of mining sites are crucial to minimize ecological damage regardless of clay type.

Choosing the Right Clay for Your Ceramic Project

White clay, known for its smooth texture and bright, neutral color, allows for vibrant glazes and intricate detailing, making it ideal for fine porcelain and decorative ceramics. Red clay, rich in iron oxide, provides durability and a rustic, earthy aesthetic suited for functional pottery like bowls and planters. Selecting between white and red clay depends on the desired finish, firing temperature compatibility, and the specific artistic or utilitarian goals of your ceramic project.

White Clay vs Red Clay Infographic

materialdif.com

materialdif.com