Oxide stains provide rich, varied color effects on ceramics by interacting directly with the clay body or glaze, often resulting in natural, earthy tones that change based on firing conditions. Underglaze offers precise, vibrant colors applied beneath the final glaze, allowing for detailed designs and consistent results regardless of firing variations. Choosing between oxide stains and underglaze depends on the desired aesthetic, with oxide stains favoring organic textures and underglaze enabling sharp, controlled decoration.

Table of Comparison

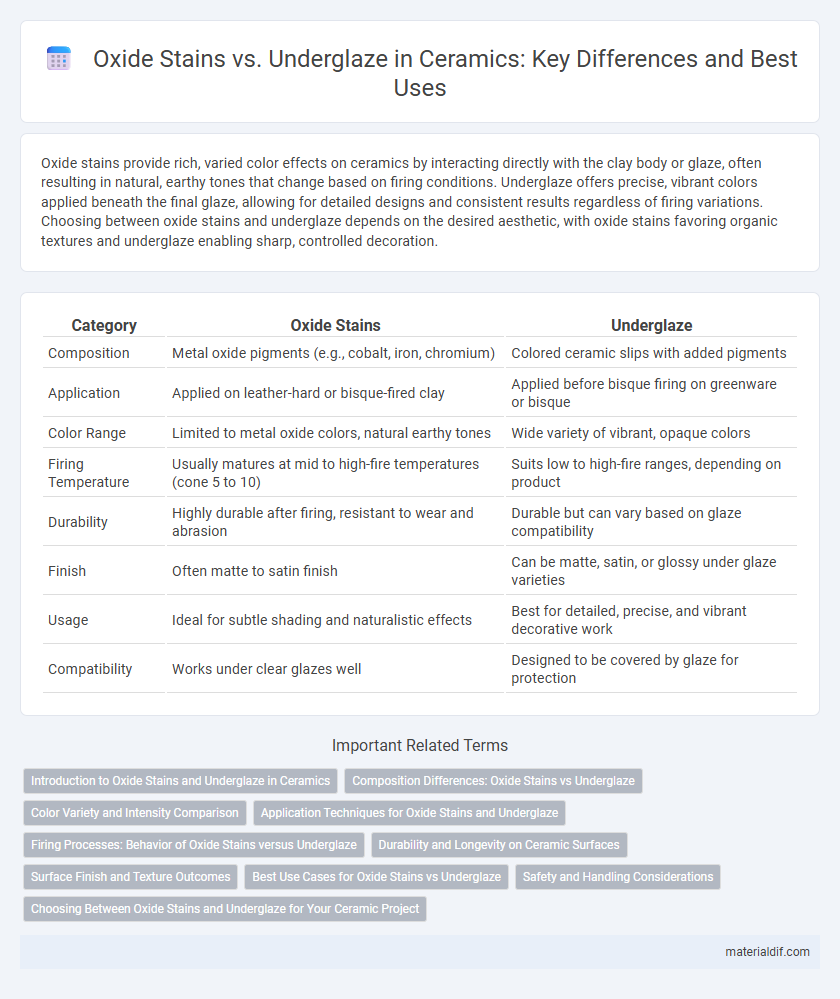

| Category | Oxide Stains | Underglaze |

|---|---|---|

| Composition | Metal oxide pigments (e.g., cobalt, iron, chromium) | Colored ceramic slips with added pigments |

| Application | Applied on leather-hard or bisque-fired clay | Applied before bisque firing on greenware or bisque |

| Color Range | Limited to metal oxide colors, natural earthy tones | Wide variety of vibrant, opaque colors |

| Firing Temperature | Usually matures at mid to high-fire temperatures (cone 5 to 10) | Suits low to high-fire ranges, depending on product |

| Durability | Highly durable after firing, resistant to wear and abrasion | Durable but can vary based on glaze compatibility |

| Finish | Often matte to satin finish | Can be matte, satin, or glossy under glaze varieties |

| Usage | Ideal for subtle shading and naturalistic effects | Best for detailed, precise, and vibrant decorative work |

| Compatibility | Works under clear glazes well | Designed to be covered by glaze for protection |

Introduction to Oxide Stains and Underglaze in Ceramics

Oxide stains in ceramics are powdered metal oxides used to create vivid surface colors and effects during firing, known for their durability and resistance to fading. Underglaze consists of colored pigments applied to pottery before glazing, allowing precise decorative patterns and detailed artwork beneath a transparent glaze. Both techniques enhance ceramic aesthetics but differ in application, with oxide stains offering raw color intensity and underglaze providing versatility for intricate designs.

Composition Differences: Oxide Stains vs Underglaze

Oxide stains consist primarily of metal oxides such as cobalt, iron, and manganese, which create color through chemical reactions during firing and tend to produce subtle, earth-toned effects. Underglazes are formulated from finely ground pigments mixed with a liquid medium, allowing for vibrant, opaque colors that remain stable under glazes after firing. The key compositional difference lies in oxide stains relying on mineral chemistry for coloration, while underglazes use synthetic or natural pigments suspended for precise application and color intensity.

Color Variety and Intensity Comparison

Oxide stains offer a limited color palette primarily consisting of earth tones such as rust, black, and sienna, providing subtle, natural hues with moderate intensity ideal for rustic effects. Underglazes deliver a broader spectrum of vibrant colors, including blues, greens, reds, and yellows, with higher color saturation and consistency suitable for detailed and vivid ceramic designs. The intensity of oxide stains is typically muted and translucent, whereas underglazes boast opaque, bold pigments that maintain their brightness after firing.

Application Techniques for Oxide Stains and Underglaze

Oxide stains are typically applied using sponges, brushes, or sprayers to create textured, natural effects on ceramic surfaces, often requiring sealing with a clear glaze to enhance durability. Underglazes offer more precision and vibrant color control, applied in layers or intricate designs before the final glaze firing, allowing for detailed patterns and consistent coverage. Both techniques demand careful surface preparation and firing protocols to maintain color integrity and adhesion on ceramic ware.

Firing Processes: Behavior of Oxide Stains versus Underglaze

Oxide stains react chemically with the clay body during firing, often resulting in variegated, unpredictable coloration that can deepen or mellow depending on temperature and atmosphere, typically showing greater variation at cone 5 to cone 10 firings. Underglazes contain stable pigments that fuse smoothly with the glaze, maintaining consistent color and sharpness after firing, particularly in oxidation or reduction atmospheres commonly used between cone 04 and cone 06. The firing process impacts oxide stains through diffusion and melting behavior, while underglazes resist fluxing, preserving detailed designs and vibrant hues.

Durability and Longevity on Ceramic Surfaces

Oxide stains, composed of metal oxides like cobalt and iron, penetrate ceramic surfaces deeply, offering superior durability and resistance to wear compared to underglaze, which primarily sits on the surface layer. Underglaze, though vibrant and versatile, is more susceptible to fading and chipping over time when exposed to heavy use or harsh cleaning. For long-lasting ceramic finishes, oxide stains provide enhanced longevity due to their chemical integration with the clay body during firing.

Surface Finish and Texture Outcomes

Oxide stains produce subtle, variegated surface finishes with an earthy, uneven texture due to their reactive nature during firing. Underglazes offer precise, consistent coloration with a smooth, matte or glossy finish, allowing for detailed designs and uniform textures. The choice between oxide stains and underglaze significantly influences the final tactile and visual qualities of ceramic pieces.

Best Use Cases for Oxide Stains vs Underglaze

Oxide stains are best used for creating subtle, natural tones and textured effects on ceramics due to their ability to blend seamlessly with clay bodies during firing. Underglaze offers more vibrant, precise color application ideal for detailed designs, patterns, and layering under a clear glaze. Choosing oxide stains favors earthy, rustic aesthetics and oxidation firing, while underglaze excels in decorative, multicolored surface treatments suited for both low-fire and high-fire ceramics.

Safety and Handling Considerations

Oxide stains in ceramics require careful handling due to their metal content and potential respiratory hazards when inhaled as dust, necessitating the use of protective masks and gloves. Underglazes, composed mainly of finely ground pigments and binders, are generally safer but still demand proper ventilation and avoidance of ingestion to prevent health risks. Both materials should be stored in sealed containers away from moisture and used in well-ventilated workspaces to minimize exposure.

Choosing Between Oxide Stains and Underglaze for Your Ceramic Project

Oxide stains offer vibrant, durable color that bonds directly with clay bodies and can withstand high firing temperatures, making them ideal for surface decoration and subtle effects. Underglazes provide a wide color palette with smooth application, allowing for detailed designs and consistent hues beneath glazes without running or fading. Choosing between oxide stains and underglaze depends on the desired visual effect, firing temperature compatibility, and the specific ceramic technique being employed.

Oxide Stains vs Underglaze Infographic

materialdif.com

materialdif.com