Vitrified tiles are highly durable and water-resistant, making them ideal for heavy traffic areas, while semi-vitrified tiles offer moderate water resistance and are better suited for low-traffic spaces. Vitrified tiles have a dense, non-porous surface created by a high-temperature firing process, providing superior strength and minimal absorption rates compared to semi-vitrified tiles. The choice between vitrified and semi-vitrified tiles depends on the specific requirements of durability, maintenance, and aesthetic appeal for the intended pet-friendly environment.

Table of Comparison

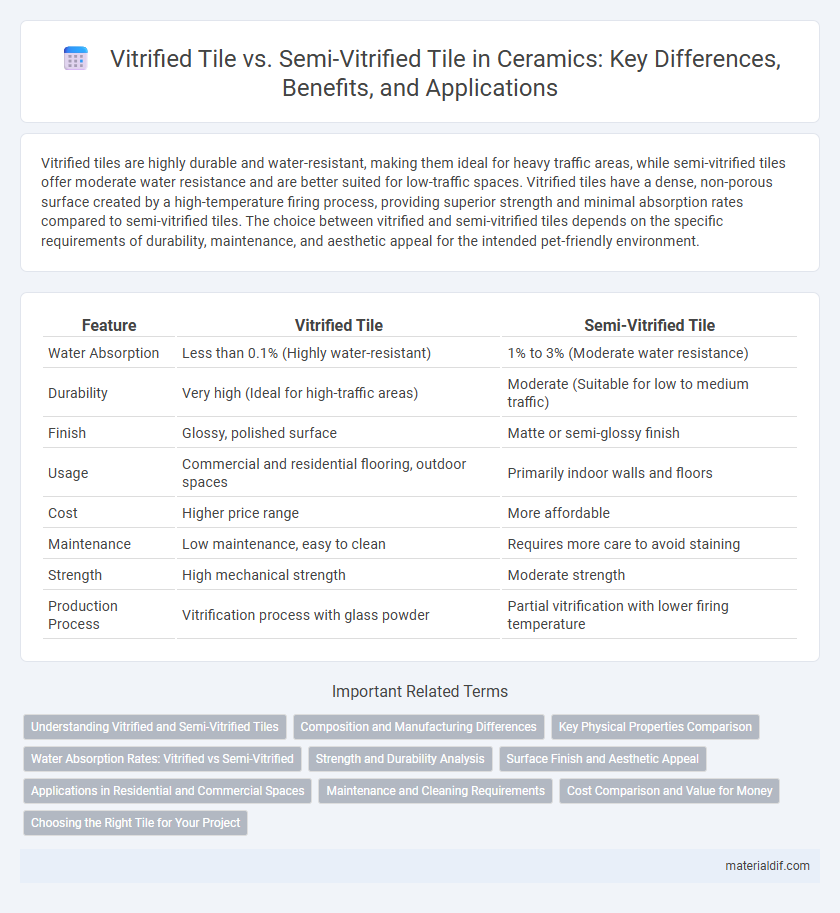

| Feature | Vitrified Tile | Semi-Vitrified Tile |

|---|---|---|

| Water Absorption | Less than 0.1% (Highly water-resistant) | 1% to 3% (Moderate water resistance) |

| Durability | Very high (Ideal for high-traffic areas) | Moderate (Suitable for low to medium traffic) |

| Finish | Glossy, polished surface | Matte or semi-glossy finish |

| Usage | Commercial and residential flooring, outdoor spaces | Primarily indoor walls and floors |

| Cost | Higher price range | More affordable |

| Maintenance | Low maintenance, easy to clean | Requires more care to avoid staining |

| Strength | High mechanical strength | Moderate strength |

| Production Process | Vitrification process with glass powder | Partial vitrification with lower firing temperature |

Understanding Vitrified and Semi-Vitrified Tiles

Vitrified tiles are manufactured through a process of vitrification that makes them denser, less porous, and highly durable compared to semi-vitrified tiles which retain some porosity. Vitrified tiles typically feature low water absorption rates below 0.05%, making them ideal for both indoor and outdoor use, while semi-vitrified tiles have absorption rates between 0.5% and 3%, limiting their usage mainly to indoor areas. The enhanced strength and resistance of vitrified tiles make them suitable for high-traffic areas, whereas semi-vitrified tiles offer moderate durability with cost-effective options for residential applications.

Composition and Manufacturing Differences

Vitrified tiles are made from a mixture of clay, quartz, feldspar, and silica, subjected to high-temperature firing that results in low porosity and high hardness, ensuring superior strength and water resistance. Semi-vitrified tiles contain a lower percentage of vitrifying agents and are fired at slightly lower temperatures, producing moderate absorbency and strength, suitable for indoor applications with less foot traffic. The key manufacturing difference lies in the vitrification process, where vitrified tiles achieve a glass-like surface through fusion, while semi-vitrified tiles retain partial porosity, affecting durability and finish quality.

Key Physical Properties Comparison

Vitrified tiles exhibit lower water absorption rates, typically below 0.05%, making them highly resistant to moisture and suitable for high-traffic areas, whereas semi-vitrified tiles have absorption rates between 3-7%, offering moderate water resistance. In terms of hardness, vitrified tiles score higher on the Mohs scale, ensuring enhanced durability and scratch resistance compared to the comparatively softer semi-vitrified tiles. Furthermore, vitrified tiles possess higher density and strength due to their non-porous composition, resulting in superior performance under heavy load conditions than semi-vitrified tiles.

Water Absorption Rates: Vitrified vs Semi-Vitrified

Vitrified tiles exhibit a water absorption rate of less than 0.05%, making them highly resistant to moisture and ideal for areas prone to water exposure. Semi-vitrified tiles have a higher water absorption rate, typically ranging between 3% to 7%, which limits their use in wet environments. Lower porosity in vitrified tiles leads to greater durability and stain resistance compared to semi-vitrified options.

Strength and Durability Analysis

Vitrified tiles exhibit higher strength and durability due to their low porosity and dense composition, making them resistant to scratches, stains, and water absorption. Semi-vitrified tiles have moderate strength with slightly higher porosity, offering decent durability but lower resistance to wear and moisture compared to vitrified tiles. The enhanced structural integrity of vitrified tiles makes them ideal for high-traffic commercial areas, while semi-vitrified tiles are better suited for residential applications with lighter usage.

Surface Finish and Aesthetic Appeal

Vitrified tiles feature a glass-like, smooth surface finish that offers superior gloss and a polished aesthetic, making them ideal for modern and luxurious interiors. Semi-vitrified tiles have a comparatively matte or satin finish, providing a more natural and textured look suitable for rustic or traditional spaces. The high-density, less porous nature of vitrified tiles results in enhanced durability and stain resistance while semi-vitrified tiles balance aesthetic appeal with cost-effectiveness.

Applications in Residential and Commercial Spaces

Vitrified tiles, known for their low porosity and high durability, are ideal for high-traffic commercial spaces like shopping malls and hospitals due to their resistance to staining and wear. Semi-vitrified tiles, with moderate water absorption and enhanced aesthetics, are preferred in residential areas such as kitchens and bathrooms where appearance and moderate durability are essential. Both tile types offer versatile solutions tailored to specific functional and design requirements in residential and commercial environments.

Maintenance and Cleaning Requirements

Vitrified tiles require minimal maintenance due to their low porosity, making them highly resistant to stains and water absorption, ideal for high-traffic areas. Semi-vitrified tiles, while slightly more porous, need regular sealing and careful cleaning to prevent moisture infiltration and staining. Both types benefit from routine sweeping and mopping with pH-neutral cleaners to maintain their surface integrity and aesthetic appeal.

Cost Comparison and Value for Money

Vitrified tiles generally cost more than semi-vitrified tiles due to their higher density and durability, making them more suitable for heavy-traffic areas. Semi-vitrified tiles offer a budget-friendly option with moderate water absorption and decent strength, ideal for residential spaces. Choosing vitrified tiles provides better long-term value for money through enhanced resistance to stains, scratches, and moisture.

Choosing the Right Tile for Your Project

Vitrified tiles, known for their low porosity and high durability, are ideal for high-traffic areas and commercial projects requiring resistance to stains and water. Semi-vitrified tiles offer a balance between aesthetics and cost, suitable for residential spaces with moderate footfall and less exposure to moisture. Evaluating the environment, usage frequency, and budget helps determine whether vitrified or semi-vitrified tiles best suit your project's functional and design needs.

Vitrified Tile vs Semi-Vitrified Tile Infographic

materialdif.com

materialdif.com